What is a pre vacuum autoclave?

A pre vacuum autoclave is an advanced type of steam sterilizer used to ensure effective sterilization of various materials.

Unlike traditional gravity autoclaves, pre vacuum models incorporate a vacuum pump that actively removes air from the sterilization chamber before the introduction of steam. This is known as the “pre vacuum phase”, and it plays a critical role in enhancing the sterilization process.

Recent research has shown that pre vacuum sterilization is significantly more efficient than gravity-based methods, particularly in penetrating porous and complex materials.

During the pre vacuum phase, multiple vacuum pulses are applied to remove trapped air from porous materials, textiles, or objects with complex geometries like medical instruments with cavities.

Air can act as a barrier to steam penetration, which is crucial for thorough sterilization. By eliminating this air, the autoclave allows the steam to uniformly penetrate even the most intricate surfaces of the items being sterilized.

This process ensures that all microorganisms, including bacteria and spores, are effectively eradicated.

Pre vacuum autoclaves are particularly useful for sterilizing loads that would be difficult to process with standard methods, such as wrapped items, surgical tools, and other heat-sensitive or moisture-sensitive equipment.

Their ability to guarantee consistent steam penetration across all surfaces makes them a reliable choice for critical applications in research, healthcare, and industrial settings.

Key features of pre vacuum sterilizers

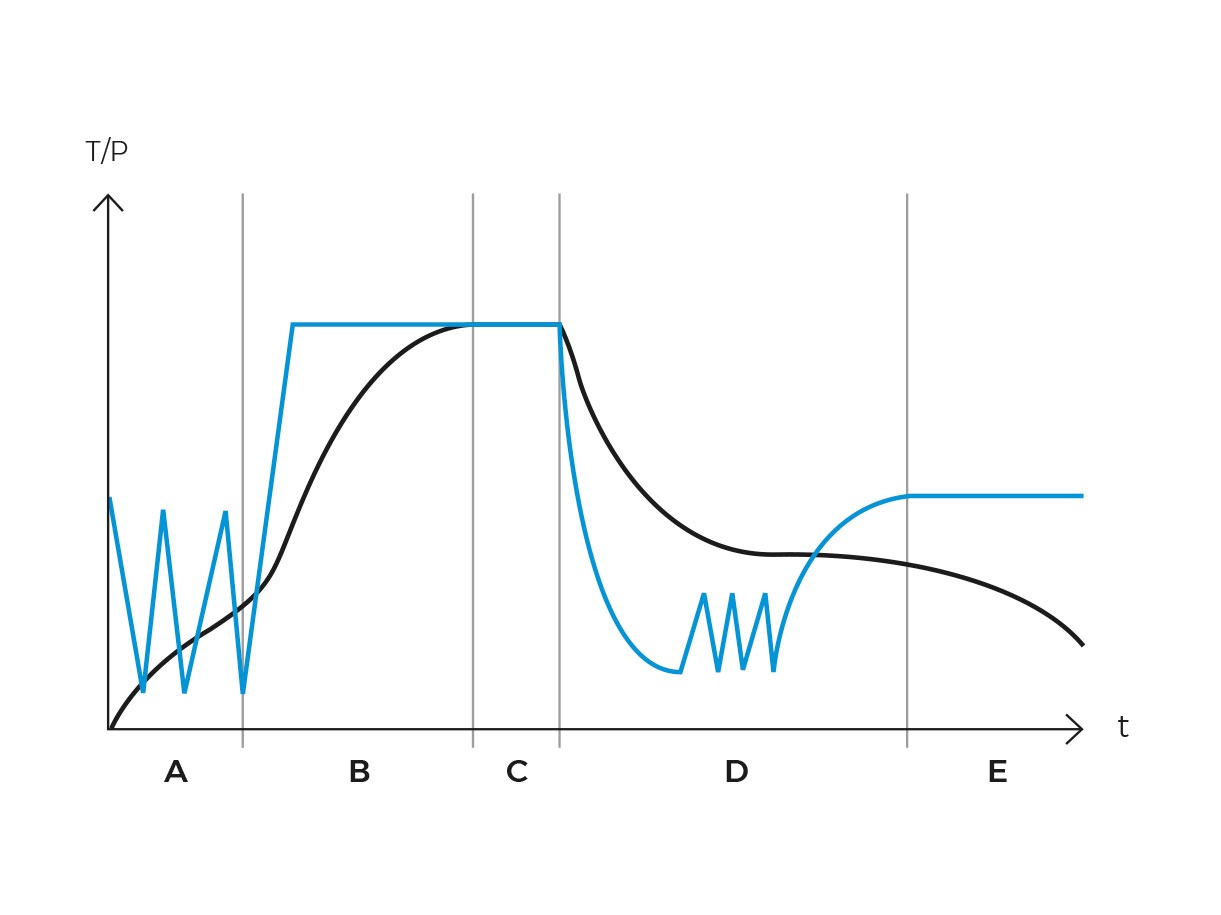

Pre vacuuming is a crucial phase in the sterilization process. At this stage, the autoclave vacuum pump mechanically extracts the air from the chamber and the load. This is accomplished through multiple vacuum pulses at -0.75 Bar, interspersed with injections of saturated steam. Typically, this cycle is repeated at least three times to ensure that all the cold air is fully replaced by steam, which is essential for the steam to thoroughly penetrate all objects.

This phase is essential for sterilizing objects such as wrapped solids, textiles, porous loads, and especially medical instruments with complex cavities and geometries. It is fundamental because, in its absence, ensuring thorough steam penetration into materials with minute cavities would be problematic, potentially leading to incomplete sterilization.

The cavities within these items trap cold air, which serves as a barrier to water vapor. Without removing this air, the efficiency of the sterilization process is compromised, posing risks of microbiological contamination. The consequences of using a contaminated medical implant in a patient are severe, increasing the likelihood of infection and sepsis dramatically.

As for the post vacuum phase, also known as the vacuum drying phase, it is conducted on solid loads and takes place after sterilization. Autoclaves equipped for this phase not only have the standard features of a pre vacuum autoclave but also include a heating jacket and a bacteriological filter.

During this phase, multiple vacuum pulses are applied similarly to the pre vacuum phase. However, the key difference is that hot air saturated with humidity is extracted and replaced with dry, cold air of lower humidity. This incoming cold air is filtered through a bacteriological filter to prevent any contamination of the sterilized load.

The goal of this phase is to eliminate all moisture from the load. To achieve this, the heating jacket is activated during the vacuum pulses, causing any condensed water within the load and on the chamber walls to evaporate. This process enables the vacuum pump to effectively remove all moisture from the autoclave’s interior.

The post vacuum phase is essential to obtain completely dry and moisture-free loads. If this is not done, any moisture remaining inside these materials and instruments could be contaminated in the future.

Certified quality pre vacuum autoclaves

Our pre vacuum autoclaves are designed to thoroughly eliminate cold air before the sterilization step and to assure complete drying of the load once the process concludes.

Our range of pre vacuum sterilizers includes a wide variety of models, corresponding to the AE-B, AHS-B, TLV-PD and TLV-DUAL Series.

These units are equipped with a steam generator and include a fractionated pre vacuum cycle. Thanks to these characteristics, they excel at sterilizing porous solid materials, wrapped objects and those with intricate geometries, among other challenging applications.

Furthermore, the AE-B, AHS-B, TLV-DUAL, and TLV-PD Series feature vacuum drying at the conclusion of the sterilization phase, effectively removing all moisture from the lead. This guarantees that the sterilized items are completely dry and ready for immediate storage or use once the cycle is finished.

Trust in sterilization equipment is essential for conducting safe and successful sterilizations, as well as for upholding quality in healthcare settings. This reliability is also essential for quality assurance in laboratories and production areas.

That is why for over 45 years, all our pre vacuum steam sterilizers have been designed and constructed at our facilities in Barcelona, reflecting our commitment to quality and our extensive experience.

This equipment is subjected to rigorous testing to ensure compliance with regulations and standards, including the European Pressure Equipment Directive (PED). With this, we strive for the highest levels of production excellence and ensure the safety of our products.

At RAYPA, we provide comprehensive solutions for our customers’ sterilization needs. With our wide range of autoclaves and the expert advice of our team, we help you find the equipment that best suits your specific requirements.

For more detailed and customized guidance on choosing the ideal autoclave for your laboratory, do not hesitate to contact our experts. Together, we can identify and provide a solution that ensures both effectiveness and safety in all your sterilization operations.

Why RAYPA?

GLOBAL REACH

With half a century of experience, we have a lengthy list of satisfied customers around the world. Currently, we export 85% of our annual turnover and have a stable network of distributors in over 100 countries.

EFFICIENT TECHNICAL SERVICE

Our team of highly qualified technicians and engineers is expert in our products. If you experience a technical issue, it will be our priority to rectify it. When you purchase a RAYPA unit, you’re guaranteed top-level support and technical assistance.

EXPERT MANUFACTURER

RAYPA is a global leader in manufacturing laboratory autoclaves. Each of our autoclaves is designed and built entirely at our facilities in Barcelona, ensuring the highest levels of production excellence.

FULL AND CUSTOMIZABLE RANGE

We offer an extensive portfolio of laboratory autoclaves to cover multiple applications and market segments. Discover the combination of autoclave model and accessories that best fits your needs within our 11 series and 35 available models.

INNOVATION AND QUALITY

Our products feature advanced technology, ongoing innovation, superior construction quality, and are designed for a long service life. Our technical and engineering staff works tirelessly every day to optimize our products and exceed our customers’ expectations.

COMPREHENSIVE CONSULTATION

Our team of specialists assesses each project and provides guidance to clients on the option that best suits their requirements. After the sale, we offer training on the use and recommended maintenance of each unit to ensure its optimal operation and extend its lifespan.