What are the features of autoclaves with fast cooling?

Autoclaves featuring fast cooling capabilities incorporate various components designed to expedite the cooling process of the autoclave load.

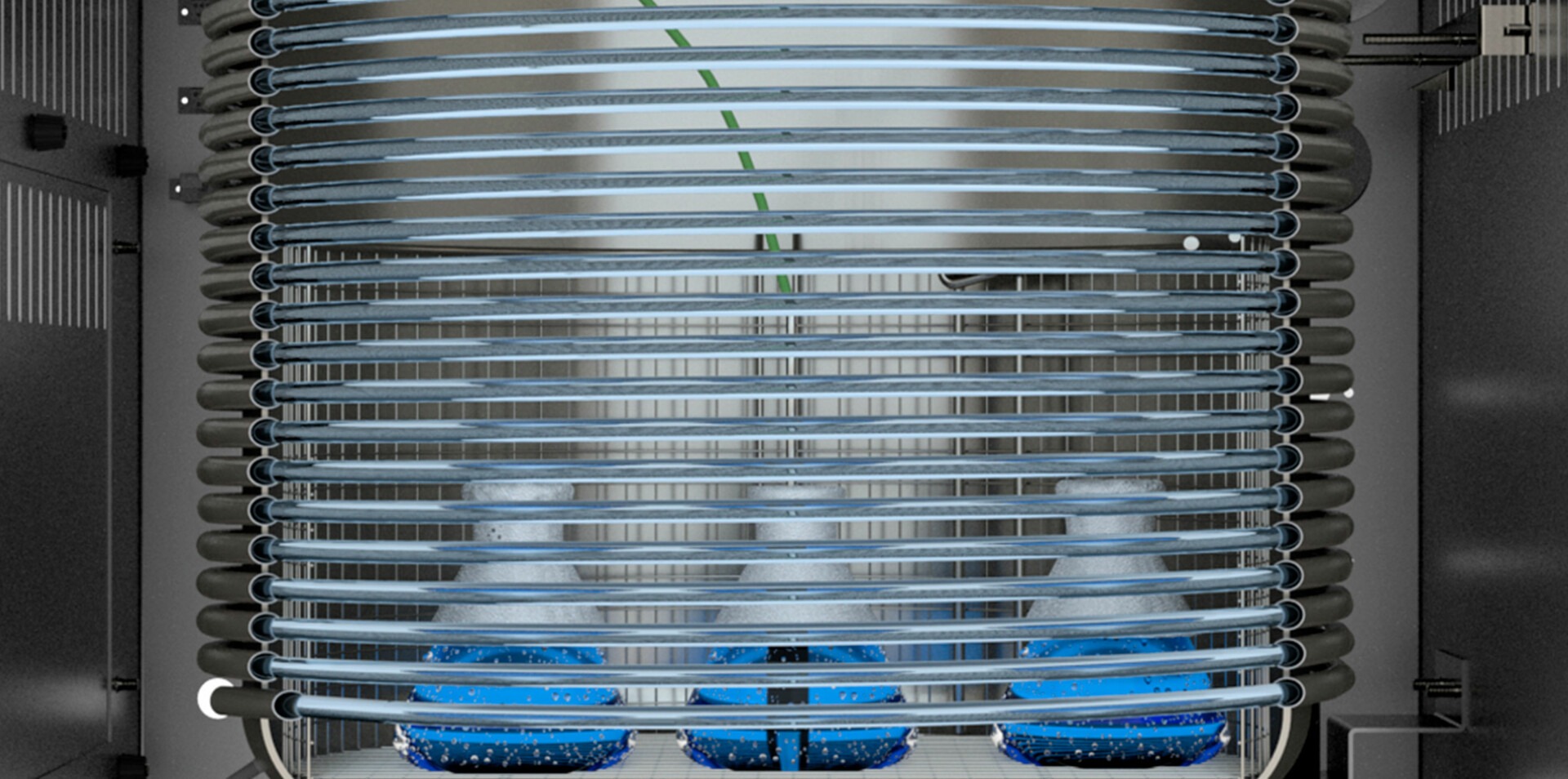

In this type of autoclave, the main chamber is surrounded by a coil-type water circuit through which cold water circulates. The internal radial fan is responsible for moving the air inside the chamber. As it moves, the air from the fan displaces heat to the walls, which are then cooled by the cold water flowing through the surrounding coil.

This system causes the air to cool rapidly, enabling both the autoclave and its contents to quickly reach the safe temperature required for opening the chamber.

Thanks to this feature, sterilized items and components are available for use much quicker, without any compromise on the quality of the process. Furthermore, sterilized liquids, objects, and instruments are better protected, as the time they are exposed to high temperatures is reduced.

In certain instances, this decrease in cooling time can surpass 70%, amounting to reductions of up to 45 minutes.

Fast cooling in this type of autoclave begins once the sterilization process has been completed. But before it starts, it is necessary to insert compressed air into the chamber. This method ensures that the internal pressure does not plummet abruptly, thus preventing complications and accidents involving the contents, such as excessive evaporation of liquids, spills, or breakages.

To properly process the load and monitor its cooling, these autoclaves are equipped with one or several flexible probes that are inserted directly into the load. This allows for the verification that the processed items have cooled sufficiently to be safely handled before opening the autoclave door.

Autoclaves with fast cooling functionality are equipped with a water coil, a flexible probe, and an air compressor for this purpose. In many cases, they also include an internal fan that serves to further accelerate the process.

Autoclaves and sterilizers with fast cooling of certified quality

At RAYPA, we design and manufacture autoclaves with fast cooling that ensure precise, safe, and efficient sterilization processes.

Our TLV-FA Series comprises vertical autoclaves with fast cooling, engineered to deliver an advanced level of liquid sterilization in both research-related settings and various industrial fields. These include the chemical industry, the pharmaceutical industry and the biotechnology industry.

In addition, they are equipped with professional traceability and are prepared to work in GLP, GMP and FDA environments.

Do you have any doubts about autoclaves with fast cooling? Contact our team of professional experts.

Why RAYPA?

GLOBAL REACH

With half a century of experience, we have a lengthy list of satisfied customers around the world. Currently, we export 85% of our annual turnover and have a stable network of distributors in over 100 countries.

EFFICIENT TECHNICAL SERVICE

Our team of highly qualified technicians and engineers is expert in our products. If you experience a technical issue, it will be our priority to rectify it. When you purchase a RAYPA unit, you’re guaranteed top-level support and technical assistance.

EXPERT MANUFACTURER

RAYPA is a global leader in manufacturing laboratory autoclaves. Each of our autoclaves is designed and built entirely at our facilities in Barcelona, ensuring the highest levels of production excellence.

FULL AND CUSTOMIZABLE RANGE

We offer an extensive portfolio of laboratory autoclaves to cover multiple applications and market segments. Discover the combination of autoclave model and accessories that best fits your needs within our 11 series and 35 available models.

INNOVATION AND QUALITY

Our products feature advanced technology, ongoing innovation, superior construction quality, and are designed for a long service life. Our technical and engineering staff works tirelessly every day to optimize our products and exceed our customers’ expectations.

COMPREHENSIVE CONSULTATION

Our team of specialists assesses each project and provides guidance to clients on the option that best suits their requirements. After the sale, we offer training on the use and recommended maintenance of each unit to ensure its optimal operation and extend its lifespan.