Innovative products

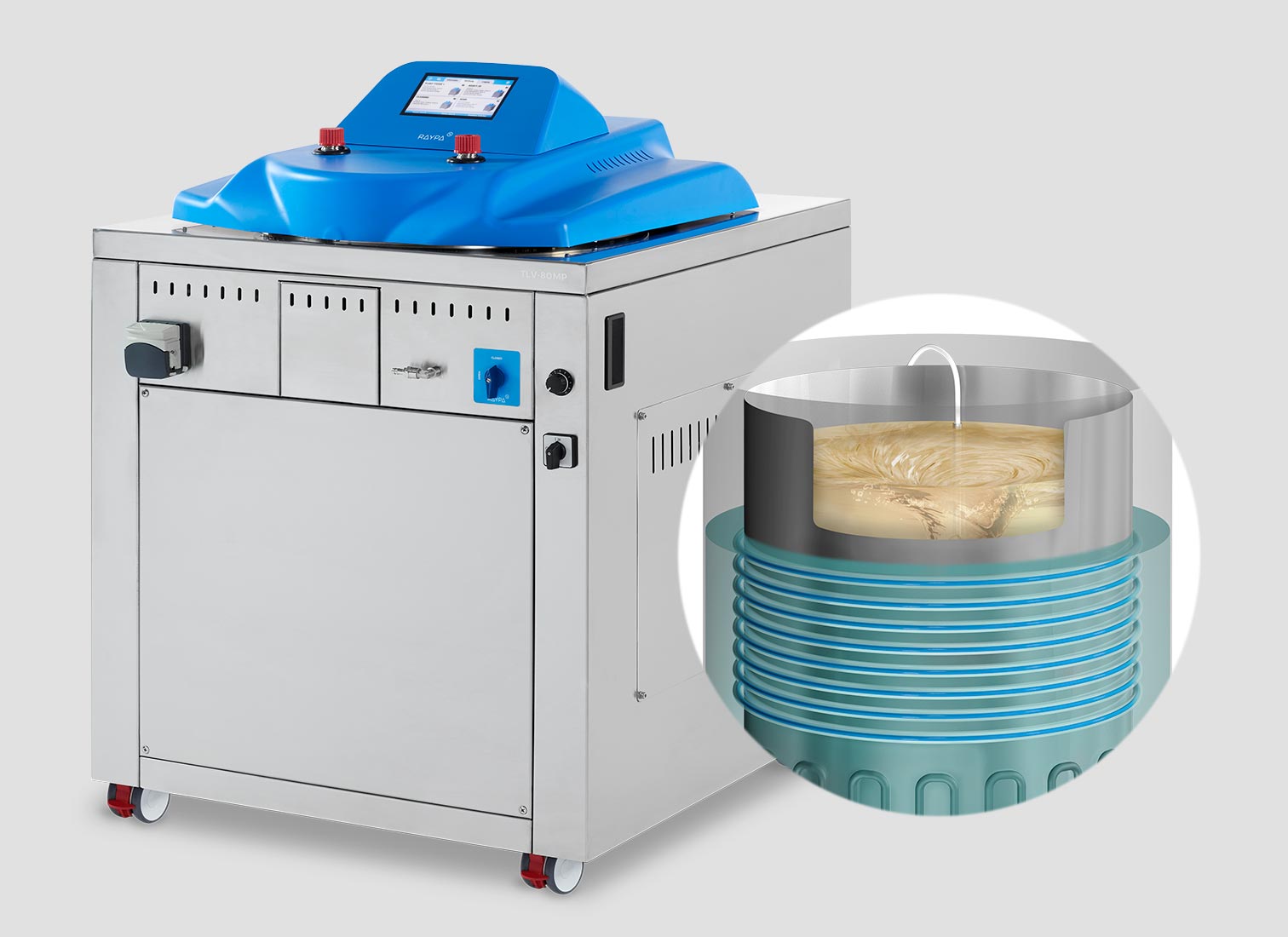

Media preparators

Featuring an innovative and ergonomic design, our AE-MP Series media preparators drastically increase the efficiency of microbiology and plant tissue culture labs. A single device incorporates the preparation, sterilization, rapid cooling, and dispensing of culture media with excellent batch-to-batch reproducibility.

Their efficient heating system and swift cooling phase cut down the media preparation time for large volumes by up to 90%. Additionally, the device is easy to clean and the dispensing lines can be cleaned and disinfected before, during, and after the dispensing phase with steam pulses that reach the entire length of the dispensing line.

Autoclaves for the pharmaceutical industry

Our TLV-FA Series autoclaves are at the forefront of sterilization technology, incorporating a rapid cooling system with a water coil, air compressor, and radial fan. This advanced technology is ideal for liquid sterilization in pharmaceutical, chemical, and biotechnology industry settings, both in research and industrial applications.

In addition to their modern design, these autoclaves are equipped with the most advanced connectivity available and comply with the latest advancements in electronic record-keeping and data control. This makes them suitable for environments regulated by FDA, GMP, and GLP standards.

View products

Advanced traceability

In our pursuit of excellence, we continuously integrate the latest in data and process traceability across all our products. We understand the importance of being able to track and monitor the performance and quality of our equipment, both for our clients and for our own operations.

Our commitment leads us to consistently invest in research and development, seeking innovative ways to enhance traceability while providing a fully digital user experience. We are at the forefront of adopting state-of-the-art technologies, such as cloud-based connectivity, to capture and analyze real-time data on the use and performance of our equipment. This approach not only aids in identifying trends and areas for improvement but also streamlines remote maintenance, updates and troubleshooting.

We believe that data traceability is a key factor in delivering value to our clients, complying with the most stringent certifications and regulations, and staying ahead of the competition. We are committed to ongoing advancements in product development to incorporate the latest breakthroughs in this area.

RAYPAcloud

All our Top line autoclaves feature a 7’’ touchscreen and can be equipped with RAYPAcloud, our cloud-based software solution. This setup enables full connectivity while complying with FDA 21 CFR Part 11 and GMP Annex 11 regulations.

Equipment status and traceability management are accessible from any device, enhancing operational flexibility. Additionally, these autoclaves facilitate remote troubleshooting and direct communication with technical support via the controller’s screen. Furthermore, RAYPAcloud is fully compatible with LIMS infrastructure in laboratory settings.

RAYPAnet

Los equipos de análisis alimentario de segunda generación cuentan con pantalla táctil de 5’’ y conexión Wi-Fi y pueden conectarse a la plataforma online RAYPAnet para el procesamiento de datos y obtener una trazabilidad de todas las operaciones realizadas en el equipo sin necesidad de instalar o descargar una aplicación o un programa. Además, toda la información se puede exportar en informes con formato PDF para su posterior consulta, estudio y almacenamiento.

Operational excellence

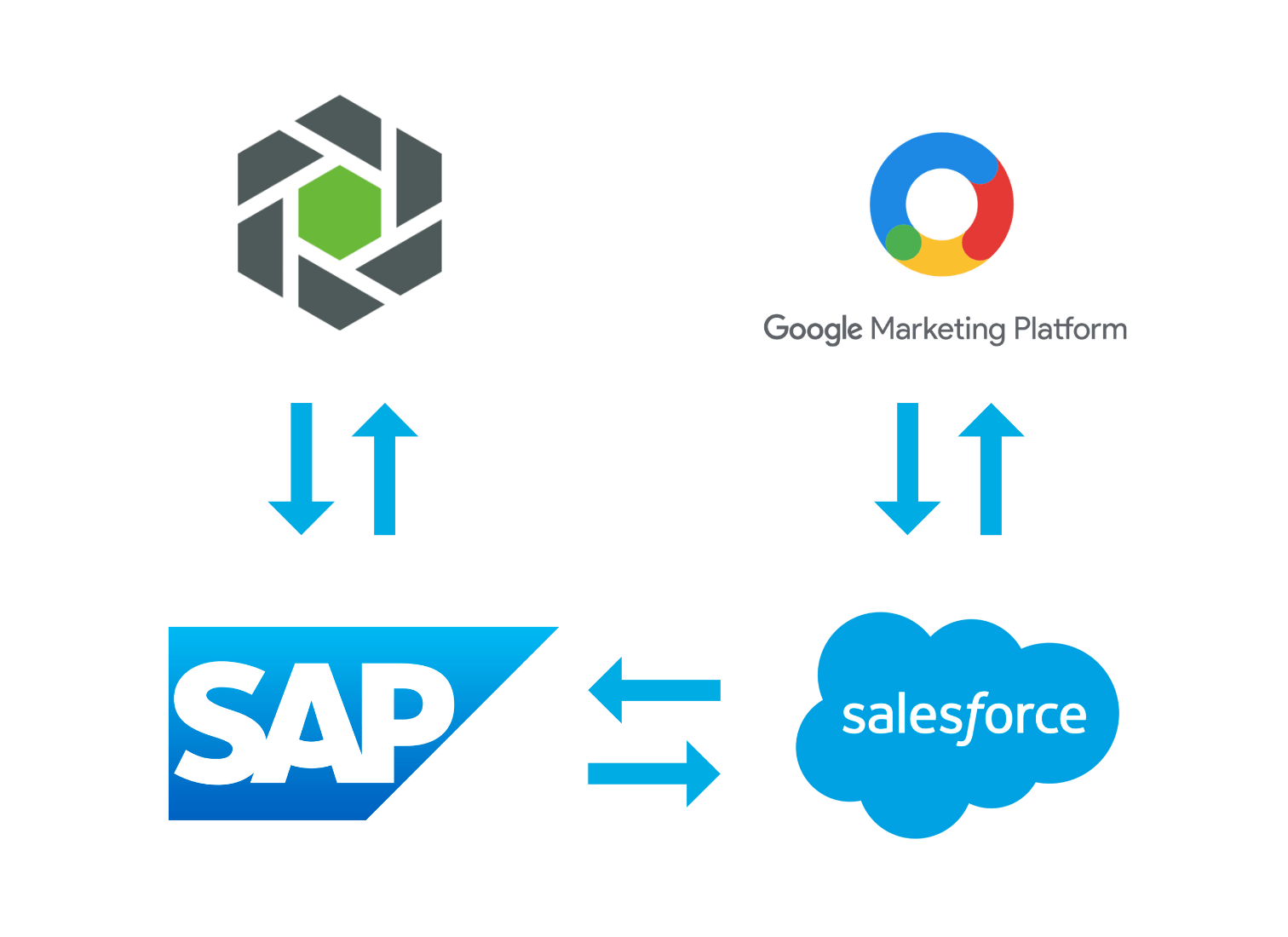

Top-tier business software

In our commitment to providing exceptional service to our clients, we partner with top-tier business software providers. This collaboration helps us effectively manage our value chain, business operations and client relationships. We are convinced that to maintain our status as a leading manufacturer, it’s crucial to adopt best practices and leverage the latest, most innovative tools. This strategy ensures we remain competitive and enhance our efficiency daily.

Summit Program

Beyond embracing ambitious business technology, we strive to utilize it purposefully. For instance, we are implementing a transformation plan called Summit, rooted in lean management philosophy, which is yielding numerous positive impacts within our company. By focusing on continuous improvement and waste reduction, we’ve optimized our processes and enhanced efficiency. This has led to cost savings, improved product quality, and increased customer satisfaction.

Our efforts to implement this lean management philosophy have fostered a culture of innovation and collaboration within the company. By involving our employees in the improvement process and empowering them to identify and address issues, we’ve seen heightened engagement and a drive for excellence. This has resulted in a more motivated and productive workforce.

Undoubtedly, the adoption of lean management philosophy has been transformative for our company. It has enabled us to refine our operations, increase our competitiveness, and deliver greater value to our customers.

Expert manufacturing

As a leading manufacturer, we are dedicated to employing the latest and most advanced manufacturing technology to enhance the quality and agility of our production. Significant financial resources are invested in state-of-the-art systems and processes that enable us to optimize our design, manufacturing, and logistics operations. Our constant pursuit is to find innovative ways to harness technology, boosting innovation, efficiency and our company’s growth.

Sustainable manufacturing

A cornerstone of our future strategy is the meticulous control and optimization of our environmental impact. We are deeply committed to advancing sustainability and supporting ecological transitions to combat climate change. A variety of initiatives have been implemented to reduce our environmental footprint and promote sustainability across all our operations. These efforts encompass investing in renewable energy sources, reducing waste and emissions, and utilizing recycled materials and eco-friendly processes. We believe that sustainability is not just a corporate responsibility but also a wellspring of innovation. We are constantly exploring new ways to lessen our impact and drive positive change for our planet.

Why RAYPA?

GLOBAL REACH

With half a century of experience, we have a lengthy list of satisfied customers around the world. Currently, we export 85% of our annual turnover and have a stable network of distributors in over 100 countries.

EFFICIENT TECHNICAL SERVICE

Our team of highly qualified technicians and engineers is expert in our products. If you experience a technical issue, it will be our priority to rectify it. When you purchase a RAYPA unit, you’re guaranteed top-level support and technical assistance.

EXPERT MANUFACTURER

RAYPA is a global leader in manufacturing laboratory autoclaves. Each of our autoclaves is designed and built entirely at our facilities in Barcelona, ensuring the highest levels of production excellence.

FULL AND CUSTOMIZABLE RANGE

We offer an extensive portfolio of laboratory autoclaves to cover multiple applications and market segments. Discover the combination of autoclave model and accessories that best fits your needs within our 11 series and 35 available models.

INNOVATION AND QUALITY

Our products feature advanced technology, ongoing innovation, superior construction quality, and are designed for a long service life. Our technical and engineering staff works tirelessly every day to optimize our products and exceed our customers’ expectations.

COMPREHENSIVE CONSULTATION

Our team of specialists assesses each project and provides guidance to clients on the option that best suits their requirements. After the sale, we offer training on the use and recommended maintenance of each unit to ensure its optimal operation and extend its lifespan.