Food analysis > Kjeldahl Distiller

Kjeldahl Distiller

Kjeldahl distiller for performing automated nitrogen analyses according to the Kjeldahl method, among various other applications.

- Pre-installed methods for the most common applications

- 5'' touchscreen and Wi-Fi connectivity for accessing RAYPAnet

- Multiple options available with varying degrees of automation

Steam distillation using a Kjeldahl distiller

Experience the versatility and durability of our Kjeldahl distillers, an essential addition to any quality control laboratory in the food industry that aims to perform precise, rigorous, and convenient measurements. Our Kjeldahl distillers go beyond mere determination of nitrogen content; they are capable of measuring volatile acidity, alcohol content, sorbic acid, among many other components.

With a successful track record spanning over 30 years in research and development, this new generation of Kjeldahl distilers is built to withstand the test of time. Constructed with materials of superior quality, its stainless steel exterior ensures its durability and resistance to wear.

Our Kjeldahl distillers are designed to meet the wide range of needs of your laboratory. With a variety of models featuring different levels of automation, we can adapt to the specific demands of each user. Each of our Kjeldahl distillers comes equipped with a 5″ color touchscreen, Wi-Fi connection for result evaluation on RAYPAnet, and offers a library of 100 customizable programs with pre-installed methods for the most common applications. Additionally, they feature dedicated menus for priming, calibration, and cleaning the reagent pumps, facilitating straightforward maintenance and ensuring the delivery of accurate and consistent results. This claim is not just our own but is also validated by our compliance with standards set by prestigious organizations like AOAC, ISO, EPA, and DIN. Adhering to these international norms confirms that you can fully trust the quality and dependability of the outcomes produced by our instruments.

Rely on our Kjeldahl distillers for your laboratory’s protein analysis needs. Leveraging our extensive experience in the market, we provide solutions that seamlessly blend into your lab operations. Reach out to us now to explore how our equipment can enhance the accuracy and efficiency of your analytical processes.

PRECISE AND OPTIMIZED DISTILLATIONS TAILORED FOR EACH APPLICATION NOTE

Our Kjeldahl distillers offer unparalleled flexibility to customize each assay. With a library of up to 100 application notes of editable name, each program allows for the configuration of various parameters, such as steam generation intensity, reagent dosing volumes, delay time, distillation time, and sample aspiration. This customization makes it possible to adjust every step of the distillation process to the specific needs of each sample, ensuring the highest quality results. Additionally, the microprocessor incorporates specialized menus for priming, calibration, and cleaning of the reagent pumps.

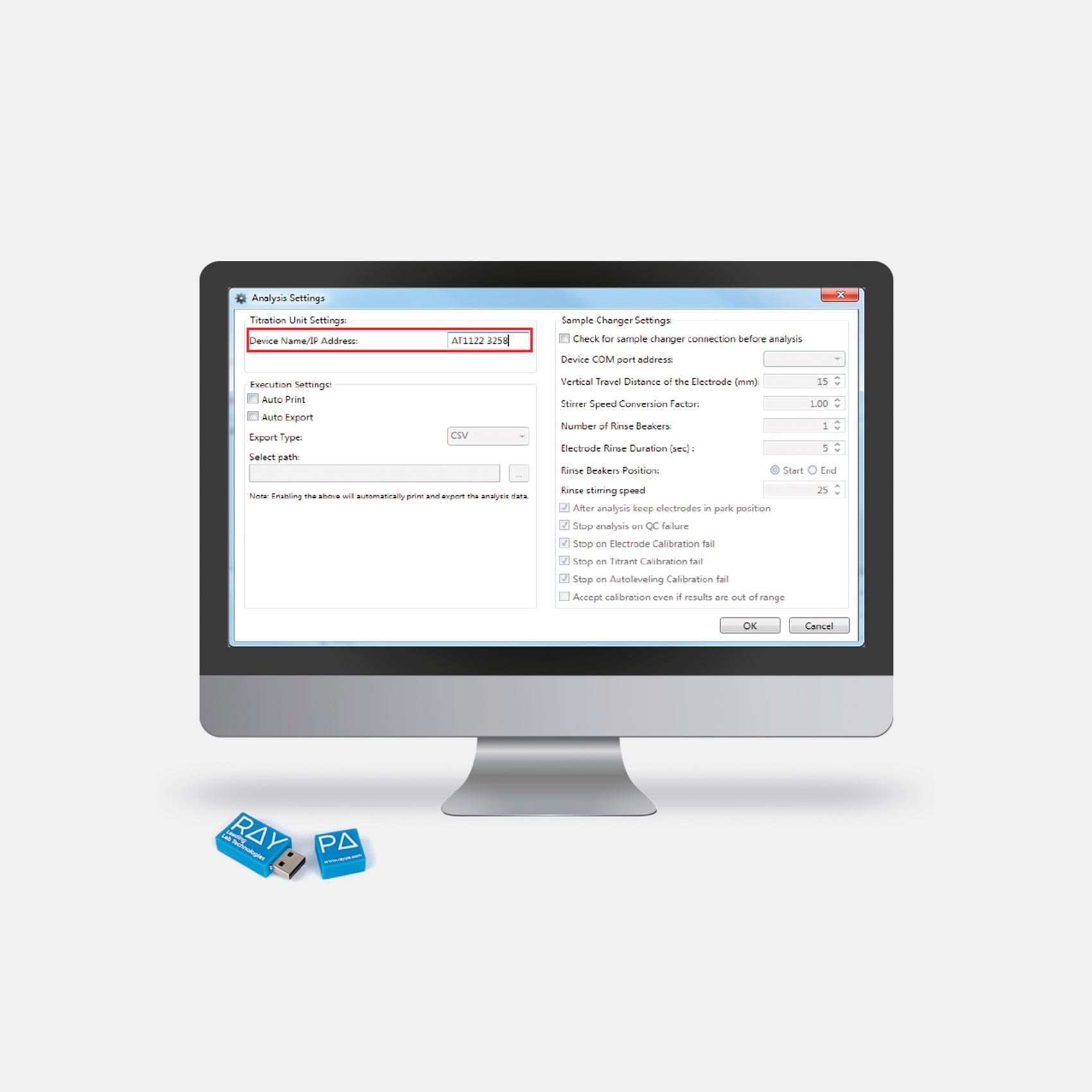

TOUCHSCREEN AND RAYPANET ACCESS VIA WI-FI

The 5'' touchscreen displays the status of all relevant parameters of each assay in real time. Moreover, each stage of the process is clearly represented with animations, icons, and timers, making it easy to understand and follow the procedure. All models come equipped with Wi-Fi connectivity for accessing the RAYPAnet web platform from any device. The results of each assay can be consulted live or retrospectively directly on the platform by accessing the historical record of assays. All information can be exported in graphic format and reports can be generated in .CSV and .PDF formats for further consultation, study, and storage. It is possible to connect and control multiple units simultaneously.

3 OPTIONS WITH VARYING DEGREES OF AUTOMATION

All models are equipped with the same safety features and contain all the essential components to perform a Kjeldahl distillation. The most automated operation model includes sample aspiration, addition of H3BO3, an external titrator that automatically determines the analysis result, and titrator control software.

Operation

KJELDAHL DISTILLATION BY STEAM DISTILLATION

Using the Kjeldahl Distiller, the process begins by loading a previously digested sample and starting a specific program. The equipment then adds the selected reagents in the exact amount. After the necessary delay time, the steam generator injects water vapor into the sample, heating it rapidly. The analyte is then carried along by the steam. First, the sample will evaporate and then condense, collecting in the receiving flask. In the next step, the nitrogen content is determined through titration, and the results are exported directly to your PC.

To make more efficient use of water, the cooling system and the steam generator of the Kjeldahl Distiller are only activated during distillation. At the end of the distillation, the remaining residue in the sample tube is aspirated and removed.

The combination of the Kjeldahl Distiller DNP-2000-TS and the external titrator TITRA-RAY offers a unique, cost-effective, and highly efficient automation of the Kjeldahl method by transferring samples, performing rapid distillations, executing precise titrations, and properly recording the results.

Applications

Technical data

| References |

|---|

| Automatic addition of receiver solution H₃BO₃ |

| Automatic removal of sample residue after distillation |

| Automatic titration with external titrator |

| External dimensions (L x D x H mm) |

| Net weight (Kg) |

| Power (W) |

| Voltage* (V) |

| Frequency (Hz) |

| *Other voltages and electrical configurations available on request. |