Food analysis > Oenologic Distiller ENODEST

Oenological distiller

Automatic oenologic distiller for rapid determination of alcoholic strength by volume of beverages

- Automatic distillation compatible with beverages of any alcohol content

- Accurate and reproducible results according to OIV, EEC 2676/90 and EC 2870/2000 standards.

- 3.5'' touchscreen and Wi-Fi connection for access to RAYPAnet

Steam distiller for determining volumetric alcohol content

Experience the efficiency and versatility of our ENODEST alcohol distiller, specifically designed to meet the demands of any laboratory focused on alcoholic beverage analysis. It’s capable of calculating the alcoholic strength by volume in beverages of any alcohol content, in compliance with OIV, EEC 2676/90, and EC 2870/2000 regulations, as well as measuring volatile acidity and sorbic acid. It’s the perfect instrument for laboratories of wineries, liqueur manufacturers, breweries, and ethanol production facilities.

With a successful track record spanning over 30 years in research and development, this new generation of the Oeonologic distiller is built to withstand the test of time. Constructed with materials of superior quality, its stainless steel exterior ensures its durability and resistance to wear.

Additionally, our Alcohol distiller features a modern design and advanced technology, including a 5″ touchscreen, Wi-Fi connectivity for result analysis on RAYPAnet, and an enhanced cooling system for efficient alcoholic sample distillation, ensuring accuracy and consistency in results.

Choose our ENODEST Alcohol distiller to elevate your analyses to a new level of efficiency and precision. Leveraging our extensive experience in the market, we provide solutions that seamlessly blend into your lab operations. Reach out to us now to explore how our equipment can enhance the accuracy and efficiency of your analytical processes.

PROFESSIONAL DETERMINATION OF ALCOHOLIC STRENGTH BY VOLUME

Our oenological distiller is equipped with an electric steam generator of adjustable power, a water addition pump for automatic sample dilution, an adapter that allows the use of different flask volumes and an optimized cooling circuit for alcohol distillation. This combination of features ensures precise and consistent results across various distilled volumes in beverages of any alcohol content, in accordance with the official standards set forth in OIV regulations, EEC 2676/90, and EC 2870/2000.

TOUCHSCREEN AND RAYPANET ACCESS VIA WI-FI

The 5'' touchscreen provides real-time updates of all relevant variables for each assay. The process steps are intuitively presented through animations, icons, and timers, simplifying the understanding and execution of the procedure. Every model comes with Wi-Fi capability, enabling connection to the RAYPAnet web platform from any device. Users can view test results in real-time or retrospectively through the platform's historical test log. Data can be exported as graphs, and reports can be produced in both .CSV and .PDF formats for subsequent review, analysis, and archiving. Moreover, it allows for the simultaneous connection and management of multiple devices.

SUPERIOR CONSTRUCTION QUALITY WITH A FOCUS ON SAFETY AS A TOP PRIORITY

Main structure made of stainless steel painted with epoxy resin for exceptional strength and durability. For user safety, the design incorporates sensors for sample tube and open door. Additionally, the system also has a dedicated display for technical personnel and an access port for inserting an external validation probe. If an error is detected, the display will show an alert message allowing for quick correction of the problem.

Operation

STEAM DISTILLATION OF ALCOHOL

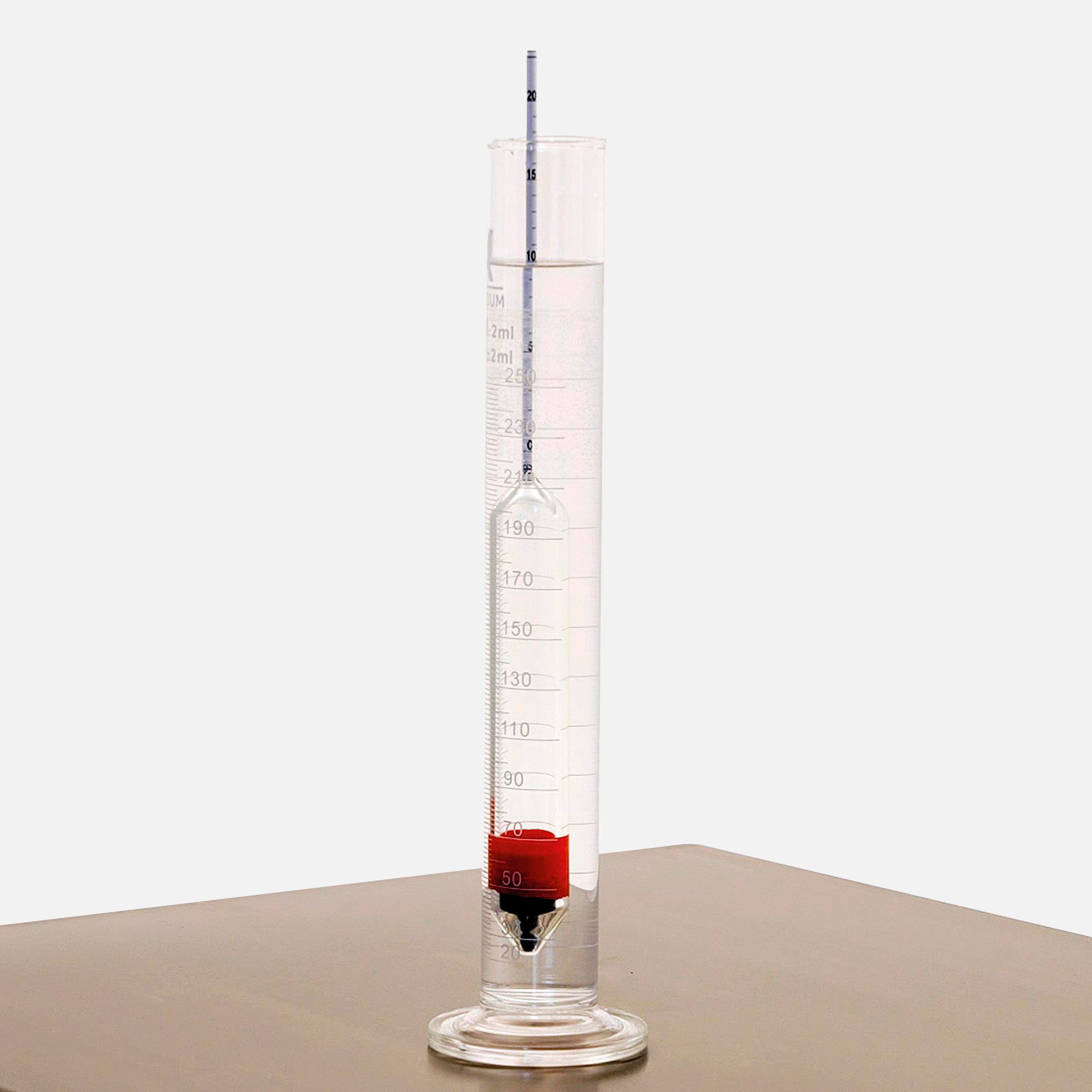

Using the oenological distiller, the process begins by loading a sample and starting a specific program. Then, the equipment adds an exact amount of water to the sample. Next, the steam generator injects water vapor into the sample, heating it rapidly. Consequently, the alcohol is carried away by the steam. It first evaporates and then, after passing through the cooling circuit, it condenses and is collected in the receiving flask. In the following step, the alcoholic strength by volume is determined by optical detection using a calibrated alcoholometer.

To enhance water efficiency, the oenological distiller’s cooling system and steam generator are activated exclusively during the distillation process.

The ENODEST alcohol distiller provides superior automation for measuring the alcoholic strength by volume. It presents a cost-effective and highly efficient option for rapid distillations, enabling accurate and digital documentation of all results.

Applications

Wineries and cellars

Red wines, White wines, Rosé wines, Cavas and sparkling wines.

Liquor factories

Whisky and Bourbon, Vodka and Neutral Spirits, Gin and Botanical Spirits, Rum and Sugar Cane Derivatives, Tequila and Mezcal, Brandy and Cognac, Fruit and Flavored Liqueurs, Cream-based and Sweet Liqueurs, Absinthe and Anise-flavored Spirits.

Breweries

Beers from commercial breweries, craft breweries, and microbreweries: lager and pilsner, ale and pale ale, stout and porter, wheat and weissbier, IPA and hop varieties, sour beers and barrel-fermented beers.

Ethanol production plants

Biofuels and sanitary applications through fermentation and distillation processes using corn and sugar cereals, cellulosic components or biomass as sources.

Technical data

| Reference |

|---|

| Distillation time (min/mL) |

| External dimensions (L x D x H mm) |

| Net weight (Kg) |

| Power (W) |

| Voltage* (V) |

| Frequency (Hz) |

| ENODEST TS |

| 7 / 200 |

| 520 x 360 x 910 |

| 27 |

| 2000 |

| 230 |

| 50/60 |

| *Other voltages and electrical configurations available on request. |

Accessories

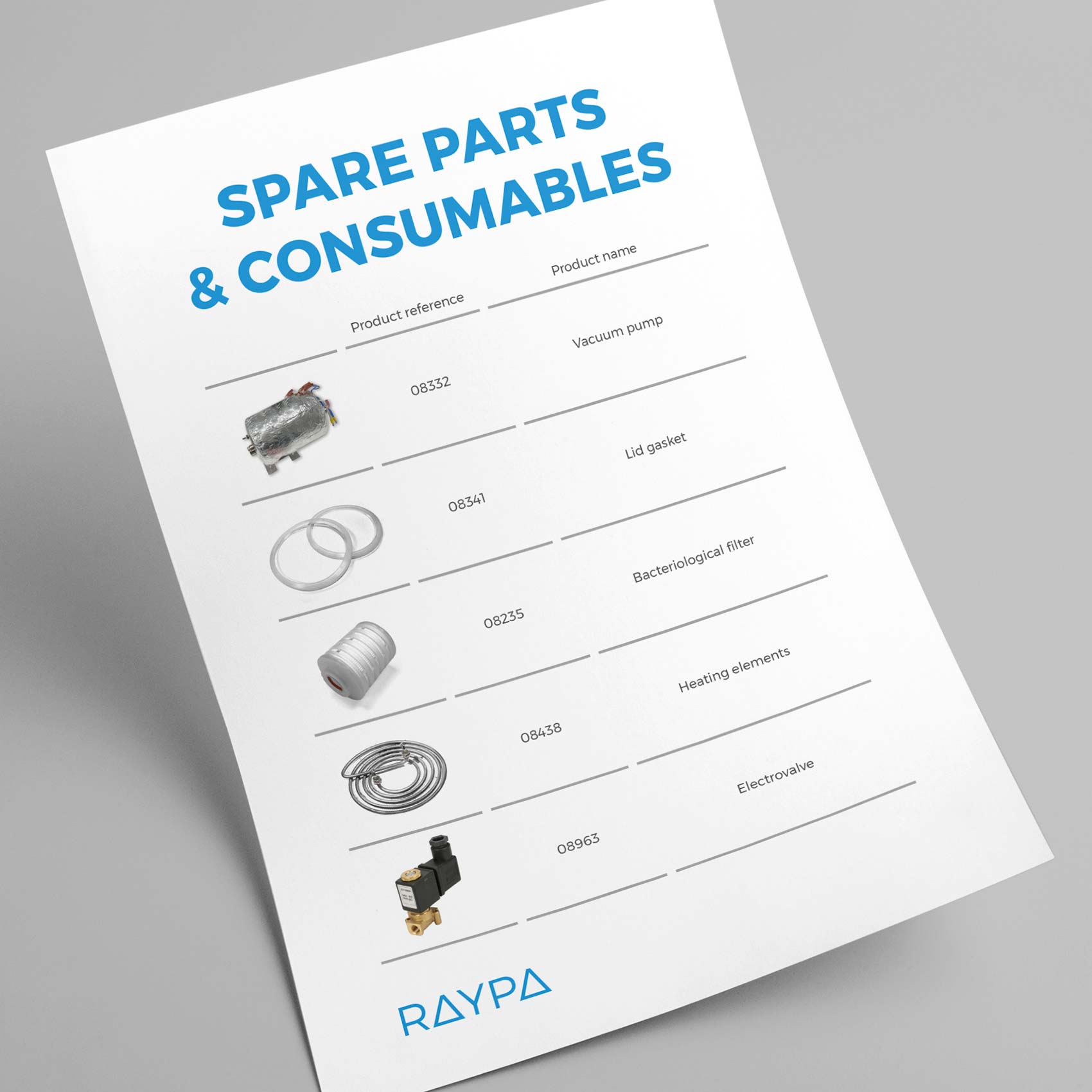

Set of consumables, spare parts and essential components

Set of original spare parts, consumables, and components, chosen specifically to adhere to each model's maintenance plan, intended to maximize equipment longevity and minimize downtime in the event of a malfunction.

Maintenance contract

A schedule of regular inspections that encompasses technical assessments, probe calibration, and adherence to the preventative maintenance plan, along with discount rates.

Remote commissioning & training

Guided remote start-up including a training session for users on the operation and maintenance of the equipment.

On-site commissioning & training

On-site guided start-up that includes the verification of the correct operation and installation of the equipment, complemented by a training session on its operation and maintenance for users.

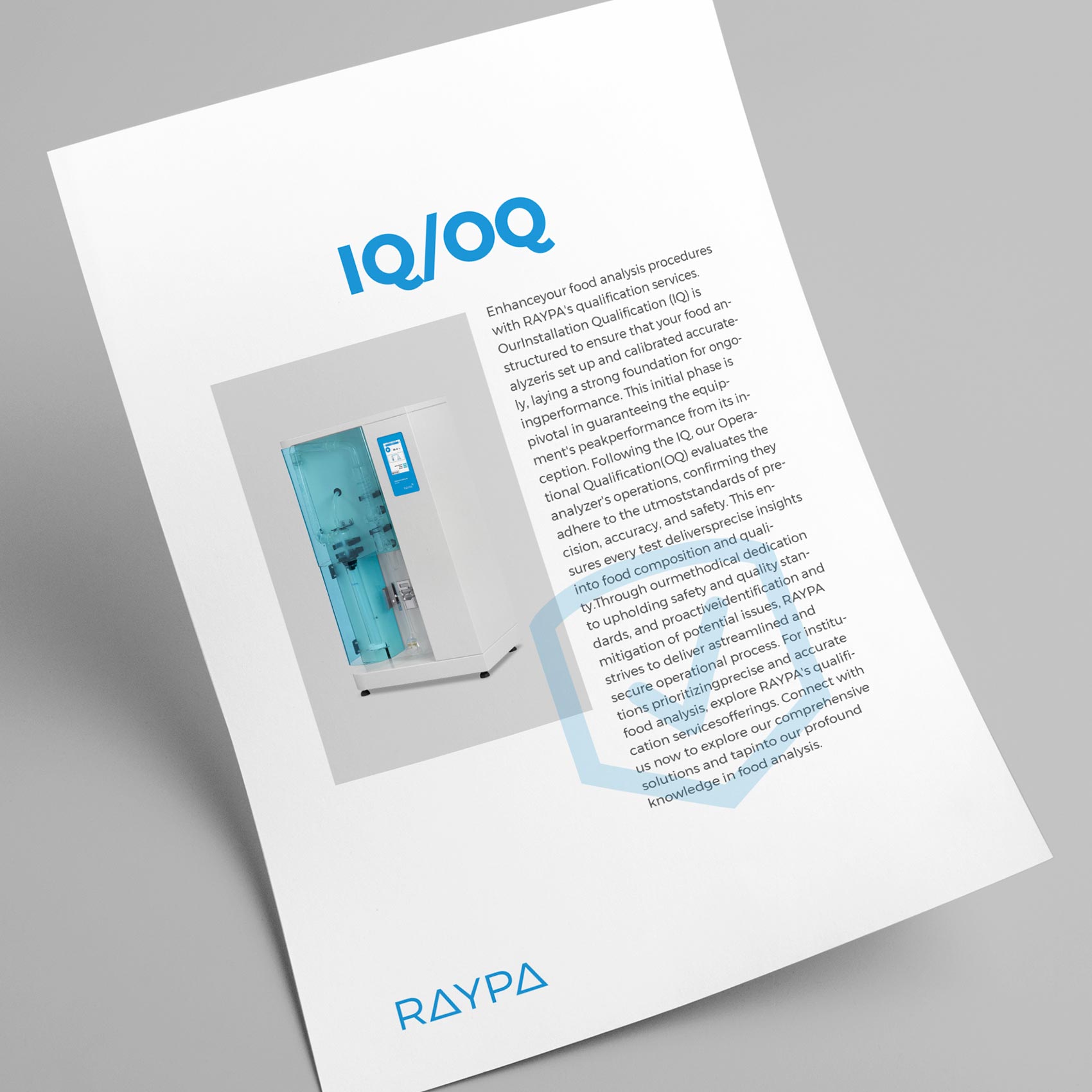

IQ-OQ-PQ Qualification

Comprehensive qualification service provided by RAYPA.

IQ-OQ Documentation

Delivery of model-specific IQ/OQ protocol and documentation for customers who prefer qualifications to be conducted by a third-party.

Warranty extension

Extended warranty up to a total of 3 years.

Consultative services in food science

Consultancy services specializing in the development of application notes, available for remote collaboration using actual samples.

Precision alcoholometer

EG-OIML class II precision glass alcoholometer. Models available with integrated Hg thermometer.

Tube racks

Stainless steel rack for distillation tubes.

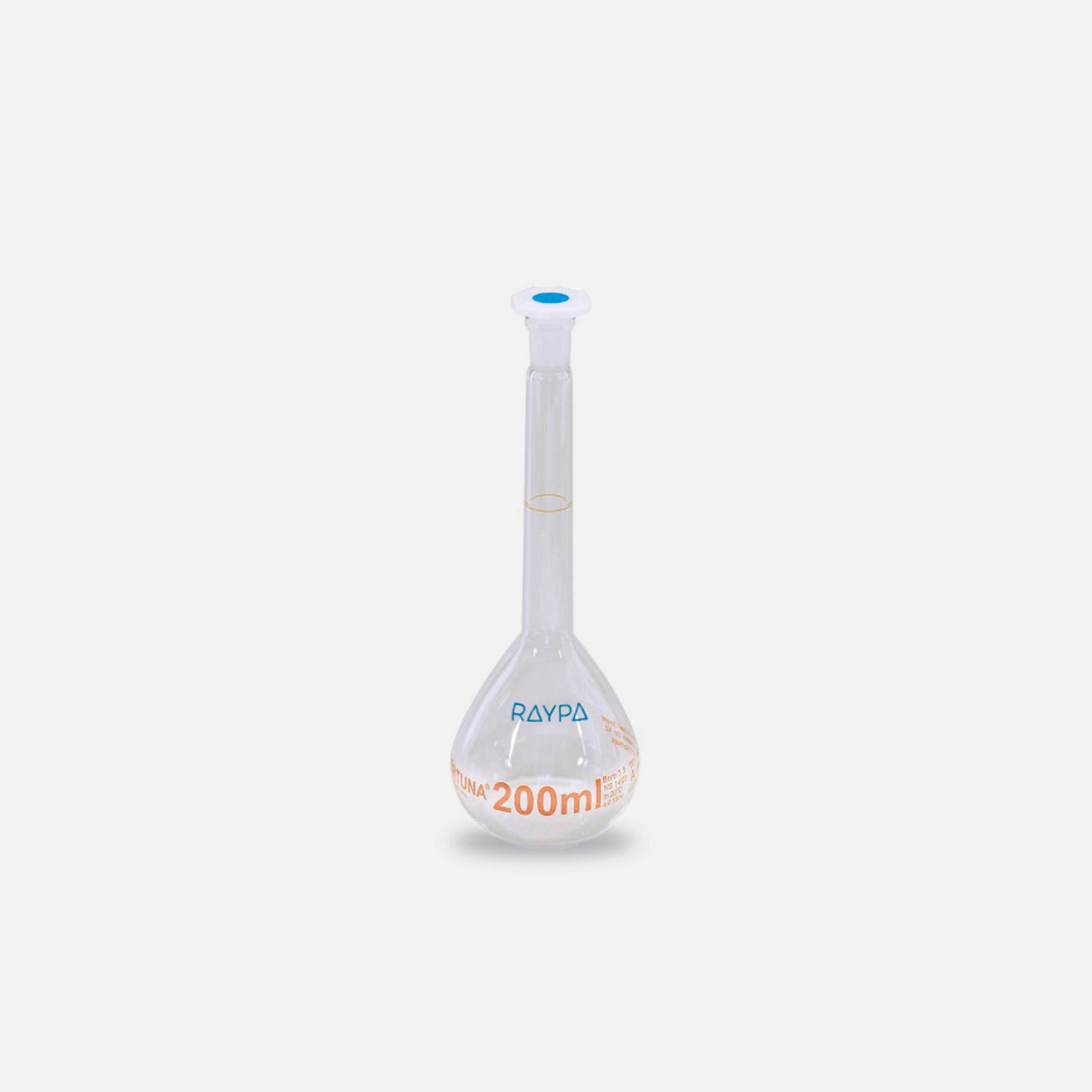

Volumetric flasks

Glass volumetric flasks to collect the distillate.

Sample tube

Large 1200ml distillation tube.

Sample tube

325ml standard distillation tube.

FAQS

When should the correction factor be applied to the distillate?

What reagents are needed to carry out distillation?

What instrument is used to measure alcohol content?

What step should be performed prior to distillation?

You may also be interested in

Cold fat extractor

Fibre extractor

Soxhlet and Randall Extractor

Kjeldahl Digester

Kjeldahl Distiller

Subscribe to our newsletter

"*" indicates required fields