Food analysis > Soxhlet y Randall SX-6 extractor

Soxhlet and Randall Extractor

Soxhlet and Randall extractor designed for rapid determination of fat content.

- Accurate and economical solvent extraction system

- Animations and alarms signal each phase change

- 3.5'' touchscreen and Wi-Fi connection for access to RAYPAnet

Solvent extraction system according to the Soxhlet and Randall methods

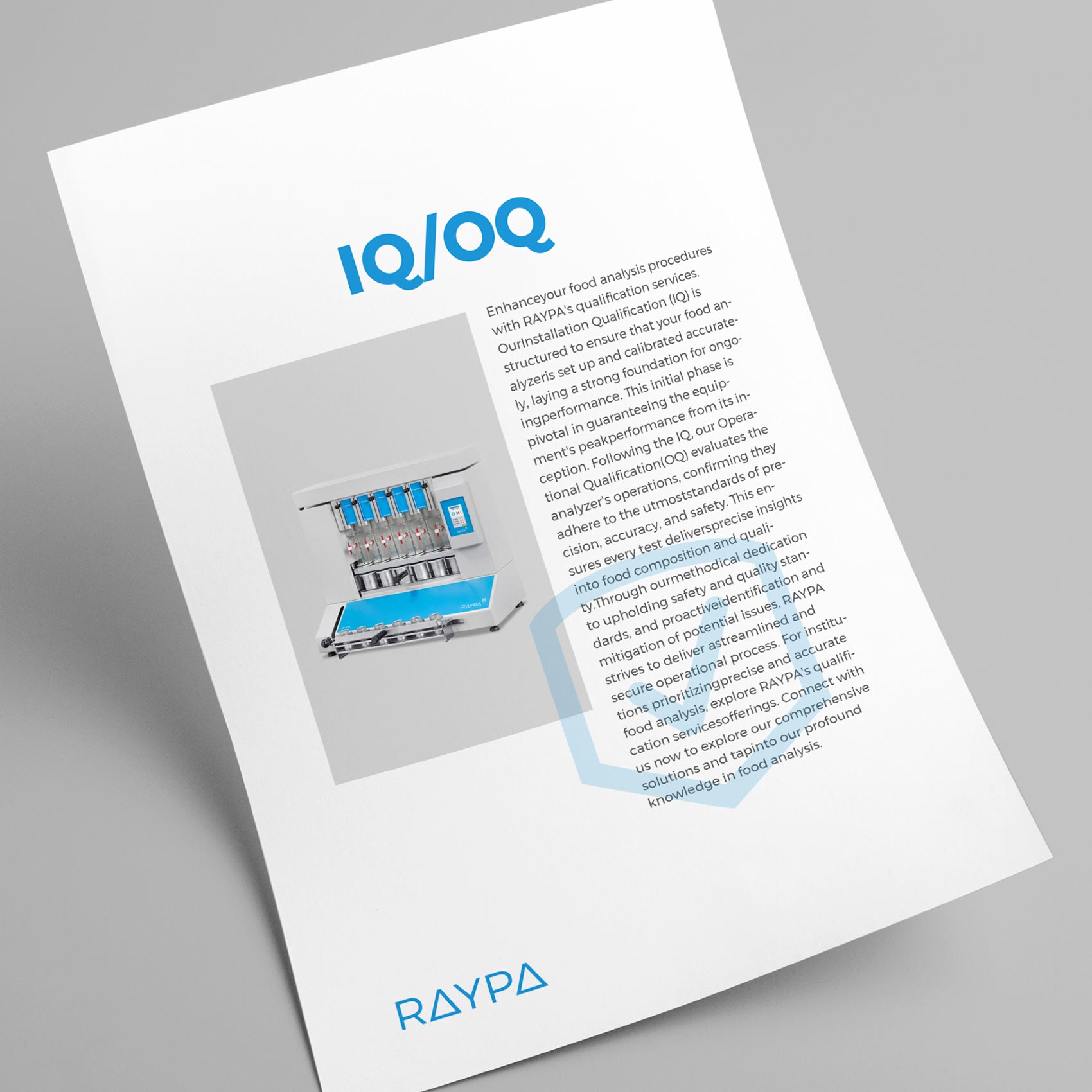

Discover the precision, speed and efficiency of extracting fat content and soluble substances of our Soxhlet and Randall extractor, engineered to perform solvent extraction according to the Soxhlet, Randall, and Twisselmann methods.

Our extractor is specially optimized for determining crude fat or other components soluble in organic solvents, catering to a broad spectrum of analytical needs. From food to soil analysis, and extending to detergents, polymers, paper pulp, fibers, rubbers, textiles, pharmaceuticals, and petrochemical products, our solution offers outstanding versatility. This claim is not just our own but is also validated by our compliance with standards set by prestigious organizations like AOAC, ISO, AACC, DIN, and EPA. Adhering to these international norms confirms that you can fully trust the quality and dependability of the outcomes produced by our instruments.

With a successful track record of over 30 years in research and development, this new generation comes equipped with a 3.5″ touchscreen and an advanced microprocessor, enabling simple and intuitive setting of parameters across up to 56 different programs. With pre-installed methods for the most common applications, it offers complete customization according to the specific needs of each application. Moreover, the integrated Wi-Fi connection allows access to RAYPAnet, facilitating the monitoring and evaluation of results.

Choose our Soxhlet and Randall extractor to elevate your analyses to a new level of efficiency and precision. Leveraging our extensive experience in the market, we provide solutions that seamlessly blend into your lab operations. Reach out to us now to explore how our equipment can enhance the accuracy and efficiency of your analytical processes.

TOUCHSCREEN DISPLAY AND COMPATIBILITY WITH A WIDE VARIETY OF SAMPLES

Our Soxhlet and Randall extractor features a 3.5'' touch screen and offers 56 programs of customizable name that can be set according to the solvent used, temperature, and extraction times for the boiling, rinsing, and recovery stages. It enables a constant monitoring of flow. Each stage of the extraction process is clearly identified with animations and timers, and it comes with an integrated solvent library.

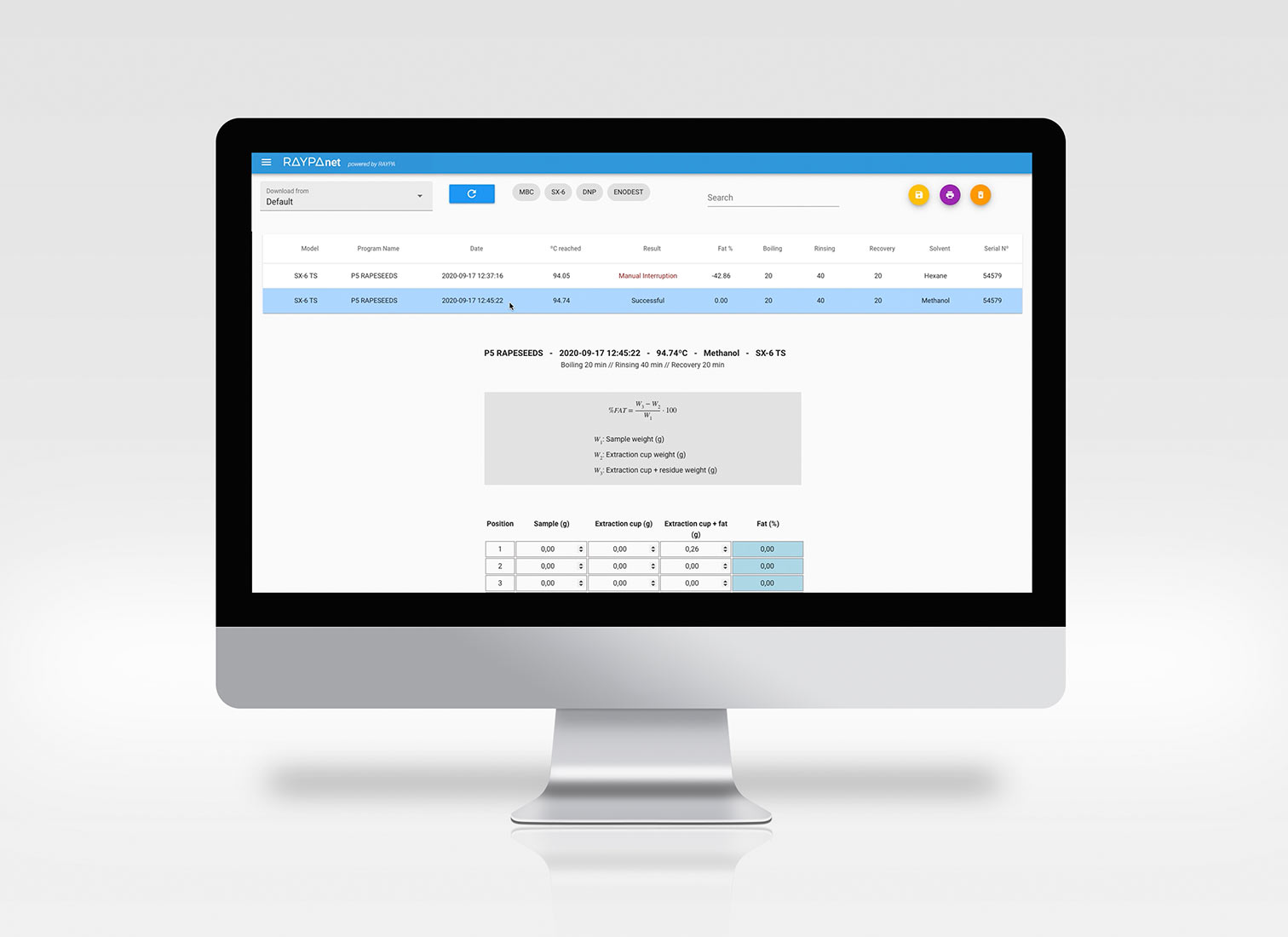

ACCESS TO RAYPANET VIA WI-FI

Every model comes with Wi-Fi capability, enabling connection to the RAYPAnet web platform from any device. Users can view test results in real-time or retrospectively through the platform's historical test log. Data can be exported as graphs, and reports can be produced in both .CSV and .PDF formats for subsequent review, analysis, and archiving. Moreover, it allows for the simultaneous connection and management of multiple devices.

SUPERIOR CONSTRUCTION QUALITY WITH A FOCUS ON SAFETY AS A TOP PRIORITY

Main structure made of stainless steel painted with epoxy resin for exceptional strength and durability. It has 6 individually adjustable simultaneous extraction positions. It includes solvent recovery tanks, all the necessary components for safe sample handling and a set of 12 Viton® and EPDM gaskets for solvent recovery. The system also has a dedicated display for technical personnel and an access port for inserting an external validation probe. If an error is detected, the display will show an alert message allowing for quick correction of the problem.

Operation

SOXHLET AND RANDALL EXTRACTION

The fat extraction process using our Soxhlet and Randall extractor is up to four times faster and ensures solvent recovery compared to the traditional Soxhlet method. The first step starts with sample preparation. Each one is weighed and placed in a cellulose extraction cartridge, then inserted into the extractor. Subsequently, extraction flasks are positioned beneath each sample, and the corresponding program is initiated.

The assay begins with immersing the sample in hot solvent, ensuring continuous fat content absorption both by immersion and reflux. The sample is placed in the extraction vessel, and then the boiling phase starts with the system completely sealed.

The next stage is the rinsing phase, where the sample is removed from contact with the condensed solvent. During this step, fat content absorption continues only by reflux.

In the final recovery stage, the solvent tank valve is closed, and the solvent is collected in a separate container for future reuse. This step allows the solvent-free fat content to settle at the bottom of the extraction flask, ensuring a clean and straightforward subsequent recovery.

Applications

Technical data

| Reference |

|---|

| Sample positions |

| External dimensions (L x D x H mm) |

| Net weight (Kg) |

| Power (W) |

| Voltage* (V) |

| Frequency (Hz) |

| *Other voltages and electrical configurations available on request. |