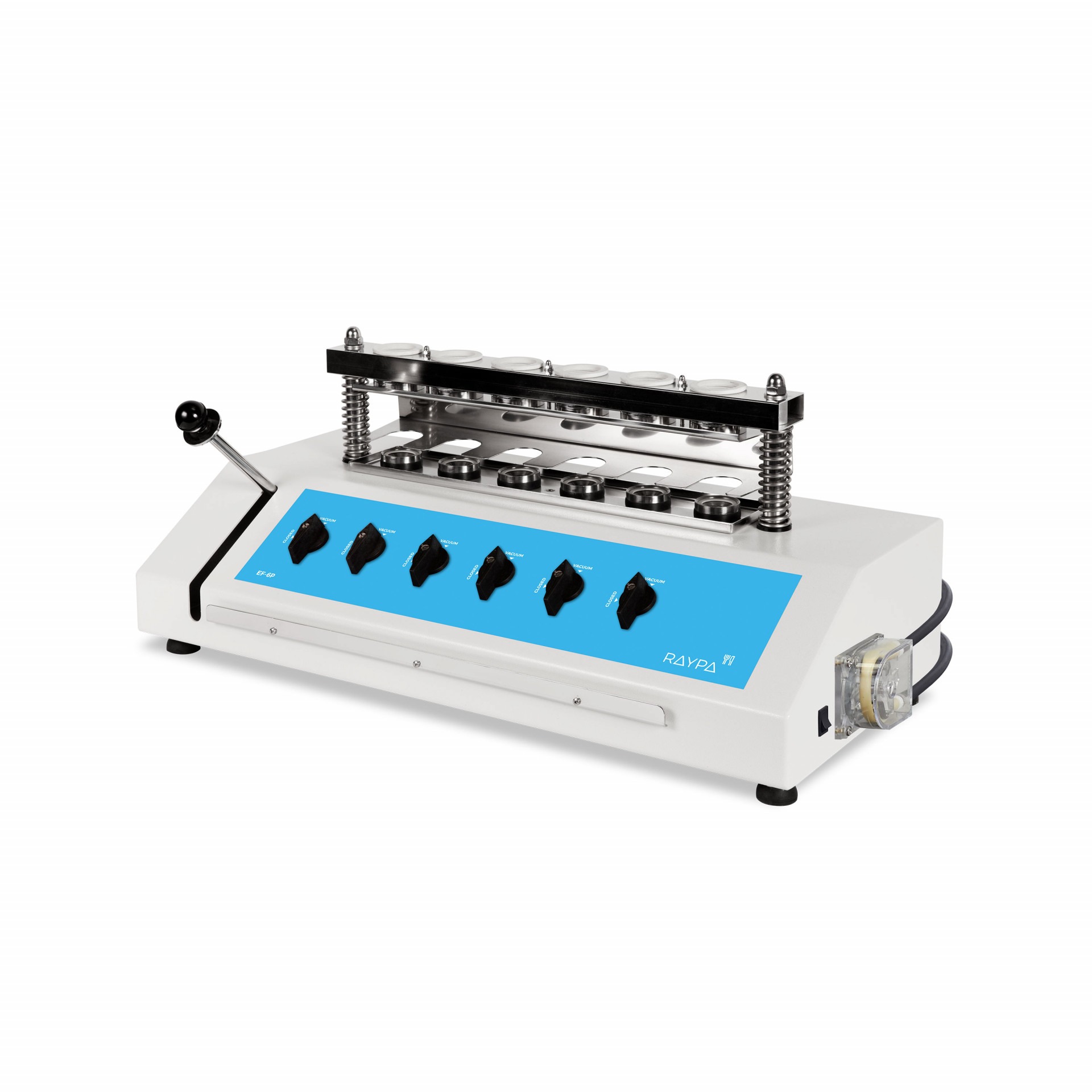

Food analysis > EF-6P Cold Fat Extractor

Cold fat extractor

Extraction system recommended for degreasing samples prior to fibre extraction or for performing cold extractions of fat content.

- Compatible with non-polar organic solvents

- Integrated negative pressure support via peristaltic pump

- Economical and fast extractions

Cold fat extraction system

Our Cold fat extractor offers a versatile, efficient, and cost-effective solution for quick cold extractions. It features 6 individually adjustable extraction positions, with an exterior made of stainless steel and includes a negative pressure support to break down clumps. It also has a connection for adding positive pressure support and allows for the recovery of solvents used in the assay.

Designed for cold fat extraction procedures using acetone or other non-polar organic solvents, it comes with EPDM and GSR tubes.

The primary recommended application is for cold fat extraction procedures using acetone or other non-polar organic solvents. When used in conjunction with the F-6P Fibre extractor, it enables the use of a source of positive pressure support to break down clumps and perform preliminary degreasing of the sample before hot fibre extraction.

COLD EXTRACTION OF FAT CONTENT

Our EF-6P cold fat extractor is used to degrease samples prior to hot fibre extraction procedures. As a stand-alone unit, the EF-6P can be used as a cold fat extractor with solvents such as acetone or other non-polar organic solvents, making it ideal for samples with more than 1% fat content and highly recommended for those with over 10%.

COMPATIBLE WITH THE FIBRE EXTRACTOR

Integrated connection with the F-6P equipment to apply positive pressure to break up compact lumps formed during filtration and accelerate extraction. It also features a negative pressure support system through an integrated peristaltic pump on the side of the unit. The extraction process is controlled by three-position valves for precise adjustment between closed, drainage, and positive pressure.

SUPERIOR CONSTRUCTION QUALITY WITH A FOCUS ON SAFETY AS A TOP PRIORITY

Made with stainless steel and coated with epoxy resin, it ensures unmatched durability and strength. Designed with 6 individual adjustable extraction positions, it includes all necessary components for safe sample handling, along with a set of 6 GSR gaskets.

Operation

Cold fat extraction with the EF-6P extractor for the analysis of lipid substances in various samples is aimed at recovering and analyzing fats and oils. This method is primarily designed for cold fat extraction procedures with acetone or other non-polar organic solvents, and also for preliminary degreasing of samples prior to hot fiber extraction.

The process starts with the preparation of the samples. Each sample is carefully weighed and placed in a crucible of known porosity. An organic solvent is then introduced into each crucible, and filtration assisted by the application of negative pressure by means of a peristaltic pump is started. During this process, compact lumps are usually generated and in those laboratories that have the fiber extractor, they can connect both equipment and use the air pump of the F-6P to apply positive pressure on the lower part of the crucibles and break these lumps.

Applications

Forage

Hay and alfalfa, Silage, Grain products, Legumes and cover crops, Fresh grasses and herbs, Energy concentrates, Mineral and vitamin supplements, Specialized feed for ruminants.

Pet food

Dry dog and cat food, Canned wet food, Therapeutic diets and vitamin supplements, Snacks and treats, Raw and natural food, Bird food, Fish and aquarium food.

Cereals

Wheat, Corn, Rice, Oats, Barley and malt, Rye, Sorghum, Millet, Granola and breakfast cereals, Whole grain and products made from whole grains.

Food and feed industry

Dairy and milk-based items, Cereals, Various meats and meat-related goods, Fish and Seafood, products derived from cocoa and chocolate, Oil and oilseeds, Nuts.

Pharmaceutical industry

Designing materials, Traditional plant-based medicines, Polymers R&D.

Environmental analysis

Wastewater, Mineral oils, Lubricants, Soils.

Technical data

| Reference |

|---|

| Sample positions |

| Dimensions of glass crucible (Ø x H mm) |

| External dimensions (L x D x H mm) |

| Net weight (Kg) |

| Power (W) |

| Voltage* (V) |

| Frequency (Hz) |

| EF-6P |

| 6 |

| 34 x 60 |

| 724 x 380 x 315 |

| 13 |

| 100 |

| 230 |

| 50/60 |

| *Other voltages and electrical configurations available on request. |

Accessories

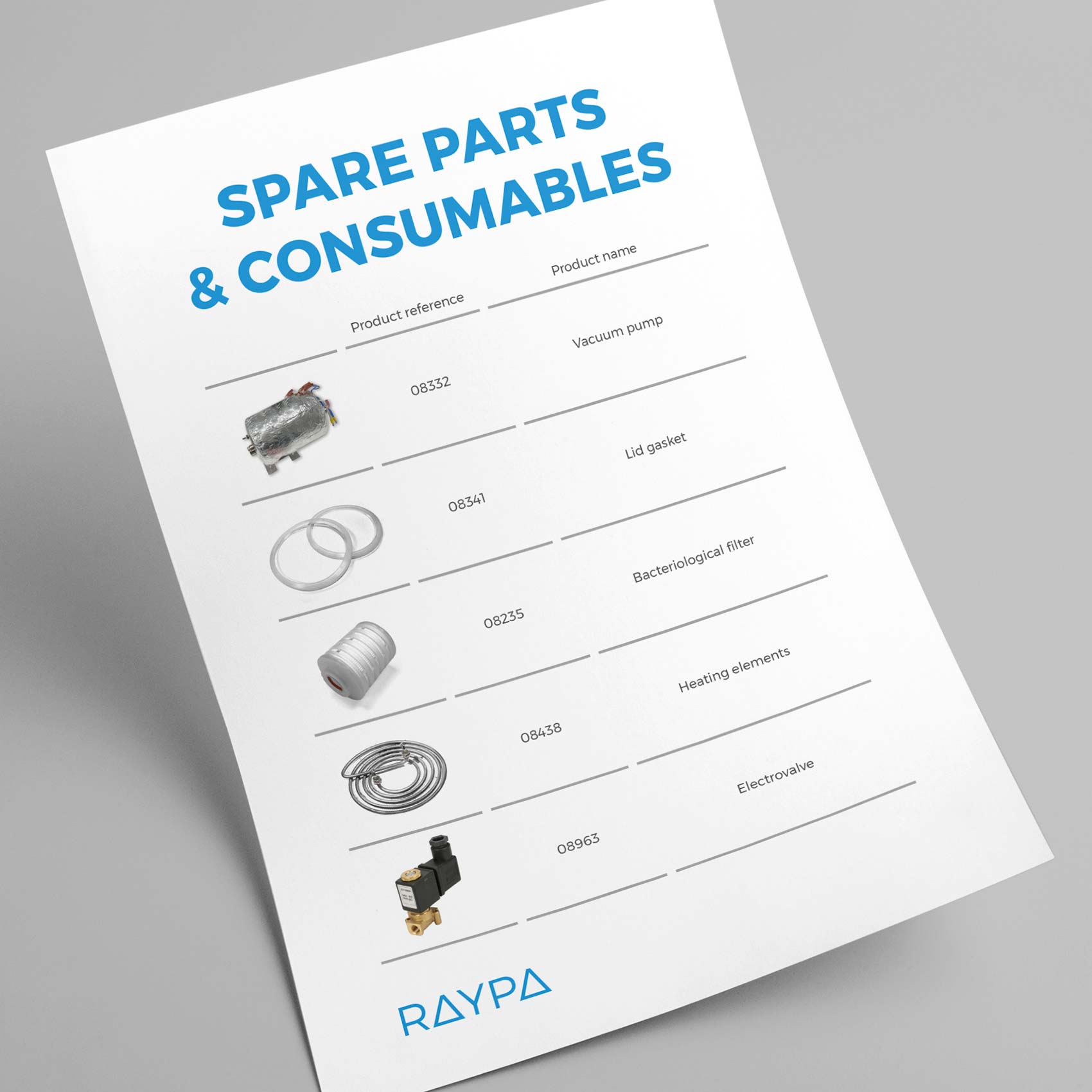

Set of consumables, spare parts and essential components

Set of original spare parts, consumables, and components, chosen specifically to adhere to each model's maintenance plan, intended to maximize equipment longevity and minimize downtime in the event of a malfunction.

Maintenance contract

A schedule of regular inspections that encompasses technical assessments, probe calibration, and adherence to the preventative maintenance plan, along with discount rates.

Remote commissioning & training

Guided remote start-up including a training session for users on the operation and maintenance of the equipment.

On-site commissioning & training

On-site guided start-up that includes the verification of the correct operation and installation of the equipment, complemented by a training session on its operation and maintenance for users.

IQ-OQ-PQ Qualification

Comprehensive qualification service provided by RAYPA.

IQ-OQ Documentation

Delivery of model-specific IQ/OQ protocol and documentation for customers who prefer qualifications to be conducted by a third-party.

Warranty extension

Extended warranty up to a total of 3 years.

Consultative services in food science

Consultancy services specializing in the development of application notes, available for remote collaboration using actual samples.

Crucible set

Set of P-2 porosity glass crucibles.

FAQS

What is the EF-6P cold fat extractor?

What are the main features of the EF-6P?

What type of samples is it suitable for?

What kind of solvents can be used with the EF-6P?

You may also be interested in

Fibre extractor

Oenological distiller

Soxhlet and Randall Extractor

Kjeldahl Digester

Kjeldahl Distiller

Subscribe to our newsletter

"*" indicates required fields