What is an autoclave and what is it used for?

Discover what an autoclave is and its importance in science and industry. Read the article for more details on its operation and applications.

At the heart of microbiology laboratories and production facilities spanning various industries, the autoclave serves as an indispensable guardian of safety, purity, and precision. This apparatus, far from being a mere adjunct, functions as a formidable barrier against contamination, vital for the integrity of scientific experiments and the safety of pharmaceutical and food products. Its role transcends basic sterilization, acting as a critical quality assurance instrument that ensures environments and processes remain devoid of pathogens and contaminants.

The autoclave, with its robust construction and capacity to withstand high pressures and temperatures, represents a pinnacle of engineering sophistication. It is essential in operations where sterility is paramount. In the realms of research and production, where the risk of contamination is ever-present, the autoclave is an invaluable asset, guaranteeing the impeccable and reliable outcomes of experiments and the consistent quality of products.

This article explores the fundamental nature of the autoclave, elucidating its crucial role across various professional settings. By detailing its operational principles and underscoring its significance, we provide a comprehensive understanding of its irreplaceable function in both science and industry. The autoclave is not merely a process component; it epitomizes the rigor and unwavering commitment to excellence that define the sectors reliant upon its capabilities.

What is an autoclave?

An autoclave is a sterilization device that plays an indispensable role in science and industry, ensuring that materials and tools are free from microorganisms. While often likened to a pressure cooker due to its ability to reach high temperatures and pressures, the autoclave surpasses this comparison with its advanced controls and safety systems. It can precisely and reliably sterilize a diverse range of items, from surgical instruments to culture media.

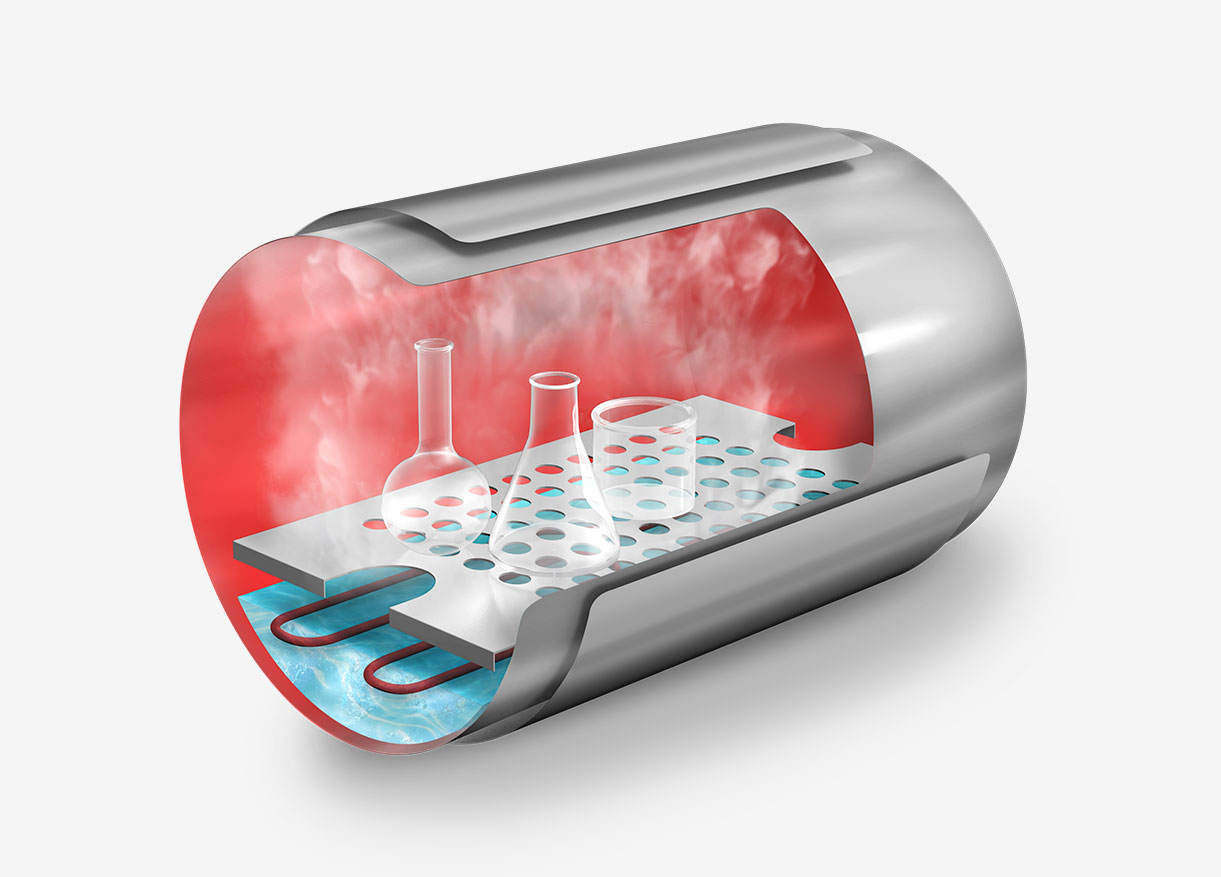

The centerpiece of an autoclave is its sterilization chamber, designed to endure the rigorous pressures and temperatures necessary for rapid and effective decontamination. These chambers come in various sizes and capacities, tailored to the specific demands of different environments, whether they be small laboratories or large industrial facilities. Selecting the appropriate autoclave involves considering factors such as the volume and type of materials to be sterilized, available space, and usage frequency.

The operating principle of an autoclave revolves around the use of saturated steam, which is exceptionally effective at heat transfer and material penetration, leading to the rapid and thorough coagulation of microbial proteins. This moist heat sterilization process is more efficient than dry heat methods, as steam can more effectively reach and maintain the temperatures necessary for complete sterilization throughout the entire load.

The sterilization cycle begins with the evacuation of air from the chamber, allowing saturated steam to fill it completely. Next, the chamber’s pressure and temperature are raised to critical levels and maintained for a specified period, tailored to the type and load of materials inside. Precise controls and real-time monitors ensure that each sterilization cycle is consistently executed, meeting the required standards for effective decontamination.

Modern autoclaves are equipped with automation technology that monitors and adjusts sterilization parameters, ensuring consistent and safe cycles. These systems not only protect the integrity of the sterilization process but also safeguard the operator, preventing accidental opening during cycles and managing any anomalies that may arise. Safety and efficiency are therefore inherent in the design and operation of contemporary autoclaves.

Upon completing a sterilization cycle, the autoclave undergoes a depressurization phase and, if necessary, a drying phase to eliminate residual moisture. This step is crucial to prevent recontamination of the sterilized materials. Once the process concludes, the sterilized items can be safely removed and are ready for use in environments where sterility is paramount, such as research labs, drug development facilities, clinical settings, and industrial food production.

What is an autoclave used for?

The autoclave transcends its role as a simple sterilization device; it stands as a bastion of safety in the fight against microbial contamination across various fields.

In research laboratories, the autoclave is indispensable for ensuring that instruments and materials are free from microorganisms that could compromise the integrity of experimental data. Sterility is a fundamental pillar in scientific methodology, and the autoclave is essential for maintaining an environment and equipment devoid of contaminants, thereby ensuring the accuracy and reproducibility of experimental results.

In the pharmaceutical industry, the autoclave is equally vital. The production of drugs and vaccines requires sterile conditions to prevent contamination that could adversely affect patient health. Autoclave sterilization is a regulatory requirement, critical not only for safety but also for the efficacy of pharmaceutical products, particularly those administered through injection or eye drops where sterility is paramount.

The autoclave’s relevance extends to the food industry, where product safety and shelf life are of utmost importance. Sterilizing packaged foods and processing equipment with an autoclave prevents the proliferation of microorganisms that cause diseases and spoilage. This process ensures that food is safe for consumption and maintains its quality and freshness for extended periods.

In biotechnology, the autoclave is indispensable for sterilizing culture media and bioprocessing equipment. Contamination in these environments can lead to the loss of valuable cell cultures or the production of defective biomolecules. The autoclave ensures that culture environments and production processes remain aseptic, which is crucial for the viability and success of biotechnological operations.

Finally, the autoclave plays a crucial role in managing biological and hazardous waste. Contaminated waste, which poses a risk to health and the environment, is effectively sterilized, transforming it into safe material for final disposal. This process not only protects public health and the well-being of healthcare and laboratory workers but also ensures compliance with environmental regulations, facilitating responsible waste handling.

Autoclave sterilization temperatures and times

Steam sterilization is widely recognized as the gold standard for sterilization across diverse applications due to its unparalleled efficiency, speed, and safety. This method ensures uniform and complete sterilization, contingent upon adherence to the manufacturer’s specifications and the specific requirements of the load.

The efficacy of steam sterilization hinges on the complete saturation of the steam within the autoclave chamber and the effective removal of air, which enables thorough penetration of the steam into every part of the materials being sterilized. While pressure is integral to the process, its primary function is to facilitate the attainment of the high temperatures essential for sterilization.

Precision in sterilizing porous materials is paramount, and autoclaves are engineered to create optimal conditions for this purpose. The required temperature for effective sterilization ranges from 115ºC to 134ºC, with the necessary time varying from 30 minutes to several hours based on the selected temperature and the nature of the load. It is imperative to adhere to the recommended time and temperature guidelines specific to each material, considering factors such as porosity, the presence of cavities, and texture, which significantly influence the process’s success.

The nature of the material being sterilized also plays a critical role. Different materials require distinct sterilization protocols; for instance, glassware and cotton clothing necessitate approximately 20 minutes and 30 minutes at 121°C, respectively. This tailored approach ensures effective sterilization without compromising the integrity of the items. The autoclave’s versatility and precise control enable it to accommodate these specific needs, providing a sterile environment indispensable for scientific research, medical practice, and industrial production.

If you have any questions, do not hesitate to reach out to our experts. Working together, we can identify and provide a solution that ensures both efficiency and safety in all your sterilization operations.