Vacuum test in autoclaves: What is it and why is it important?

Learn the importance and procedure of the vacuum test in autoclaves to ensure effective and safe sterilization. Read the article to get all the essential information.

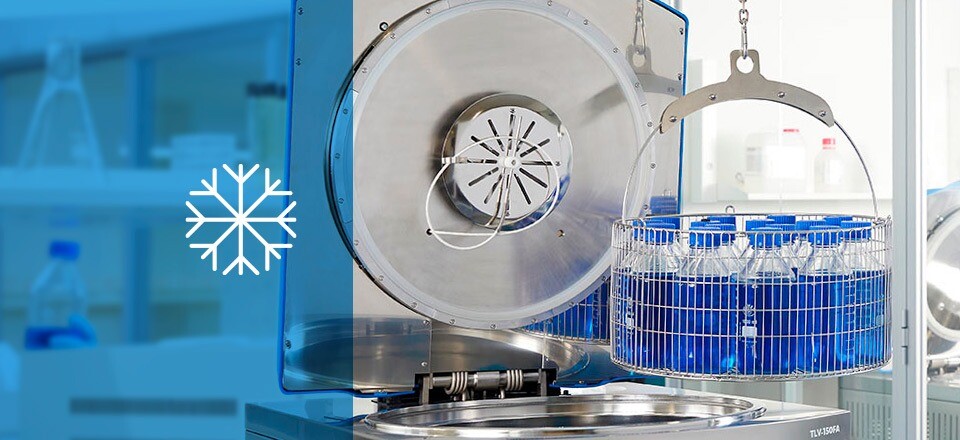

The vacuum test in an autoclave is a fundamental procedure to ensure the hermetic integrity of the chamber and the piping system of an autoclave, as well as to verify the proper functioning of the equipment’s vacuum system.

This evaluation subjects the autoclave to vacuum conditions, measuring the vacuum loss over time. In this article, we will explain what this test evaluates, its procedure and operation, and when it is recommended to perform it, based on industry best practices and standards.

The importance of proper performance of an autoclave’s vacuum system

For autoclave sterilization to be effective, it is essential that steam comes into contact with all surfaces to be sterilized. This is because steam, as the sterilizing agent, transfers its energy by conduction and condensation, i.e., by transitioning from a gaseous to a liquid state. Therefore, it is crucial that nothing obstructs the steam’s access to the surfaces that need to be sterilized. For this reason, ensuring the creation of a quality vacuum before generating steam is vital.

If air is not properly removed from the chamber, the nitrogen and other gases present in the air act as an insulating barrier between the steam and the object to be sterilized, thereby compromising the effectiveness of the sterilization process.

What does the vacuum test evaluate?

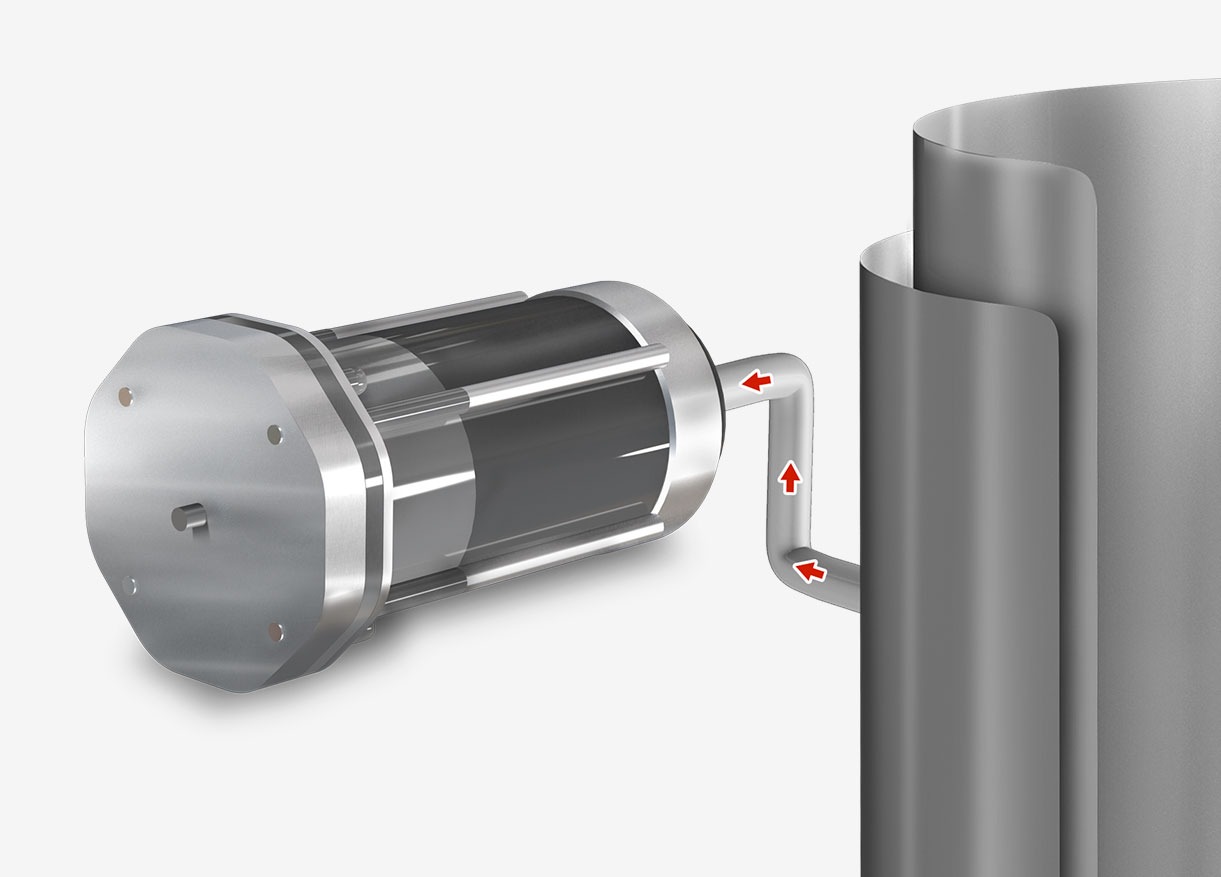

The main objective of the vacuum test is to verify the hermeticity of the chamber and the piping system of the autoclave, ensuring that there are no air leaks that could compromise the sterilization process. This test is crucial to confirm that the sterilization chamber is perfectly sealed, meaning that there is no unexplained decrease in the vacuum level. It helps identify potential failures in the vacuum pump’s operation, the sealing of solenoid valves, the presence of air leaks in the door gasket or pipe connections, and whether the vacuum levels defined by the manufacturer have been achieved.

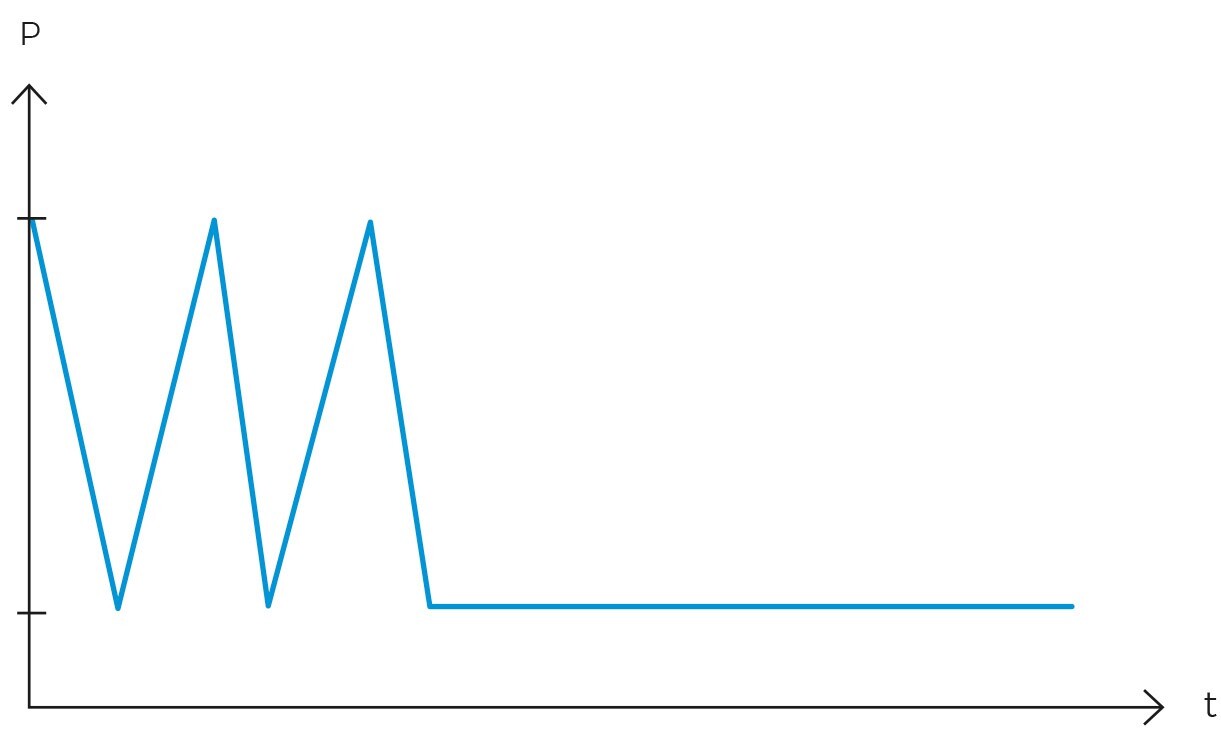

During the test, the autoclave is subjected to a vacuum cycle, and the amount of vacuum lost over a specific period is measured. A typical cycle includes three vacuum pulses, followed by a 15-minute hold time in a deep vacuum. At the end of the test, the leak rate is measured in units such as kPa/min, mbar/min, or mmHg/min. Most industry standards establish that an acceptable leak rate is 1 mmHg/min or less.

Procedure and operation of the vacuum test

The procedure for conducting a vacuum test includes several stages to ensure the accuracy and reliability of the results. Generally, any pre-vacuum autoclave comes from the factory with the specific program for this test in its program memory. To carry out the test, the following steps should be followed:

- Preparation: The autoclave must be empty and clean. All removable accessories, such as trays, racks, or supports, should be removed to avoid interference with the test.

- Cycle Start: The corresponding vacuum test cycle program is executed. The autoclave will start by performing three vacuum pulses, eliminating air from the system and then allowing it to return to atmospheric pressure, repeating this process three times.

- Holding Time: After the three vacuum pulses, the autoclave maintains a deep vacuum for 15 minutes. During this period, the vacuum loss is quantified.

- Results: At the end of the cycle, the autoclave displays the leak rate. This result is compared with industry standards or the user’s specific criteria to determine if the autoclave passes or fails the test.

As you can see, the correct outcome of this procedure is essential to ensure that the autoclave operates properly and can perform effective vacuum sterilization cycles.

When should the vacuum test be performed?

The frequency with which the vacuum test should be performed depends on the standard operating procedures (SOP) of each laboratory and the risk tolerance of each facility. Logically, centers that sterilize surgical, laparoscopic, or dental instruments will have a shorter interval for conducting this control test than a school microbiology laboratory. However, performing this test regularly is important as it provides evidence of the structural integrity of the autoclave and its vacuum system.

While any autoclave from any manufacturer is calibrated and checked at the factory, it is essential to periodically validate the proper functioning of pre-vacuum autoclaves using this test. This validation includes not only the vacuum test but also other operational tests, such as the Bowie-Dick test, spore tests, or sterilization control tape. Regularly performing these tests is fundamental to maintaining rigorous control over the sterilization process.

In addition to the frequency determined by each laboratory’s SOP, it is advisable to perform the vacuum test after any repair, maintenance, or replacement of the autoclave gasket. These situations can affect the equipment’s performance, and a vacuum test helps verify that everything is working properly.

In summary, the vacuum test is a crucial part of the maintenance and validation of autoclaves with vacuum systems. Its implementation ensures the optimal functioning of these devices, thereby guaranteeing the effectiveness of the sterilization process and the safety of sterilized products.