The vacuum cycle

Discover how the vacuum cycle in autoclaves improves sterilization by removing air, enabling a more efficient penetration of steam and improving microbial eradication. Read the article for more details.

The prevacuum cycle, one of the most fundamental types of sterilization cycles used in autoclaves, employs saturated steam under pressure to eradicate microorganisms and spores. This cycle is distinguished from the gravity cycle by utilizing a mechanized vacuum system to remove air from the sterilization chamber before the introduction of steam, thereby allowing for deeper steam penetration and more robust sterilization.

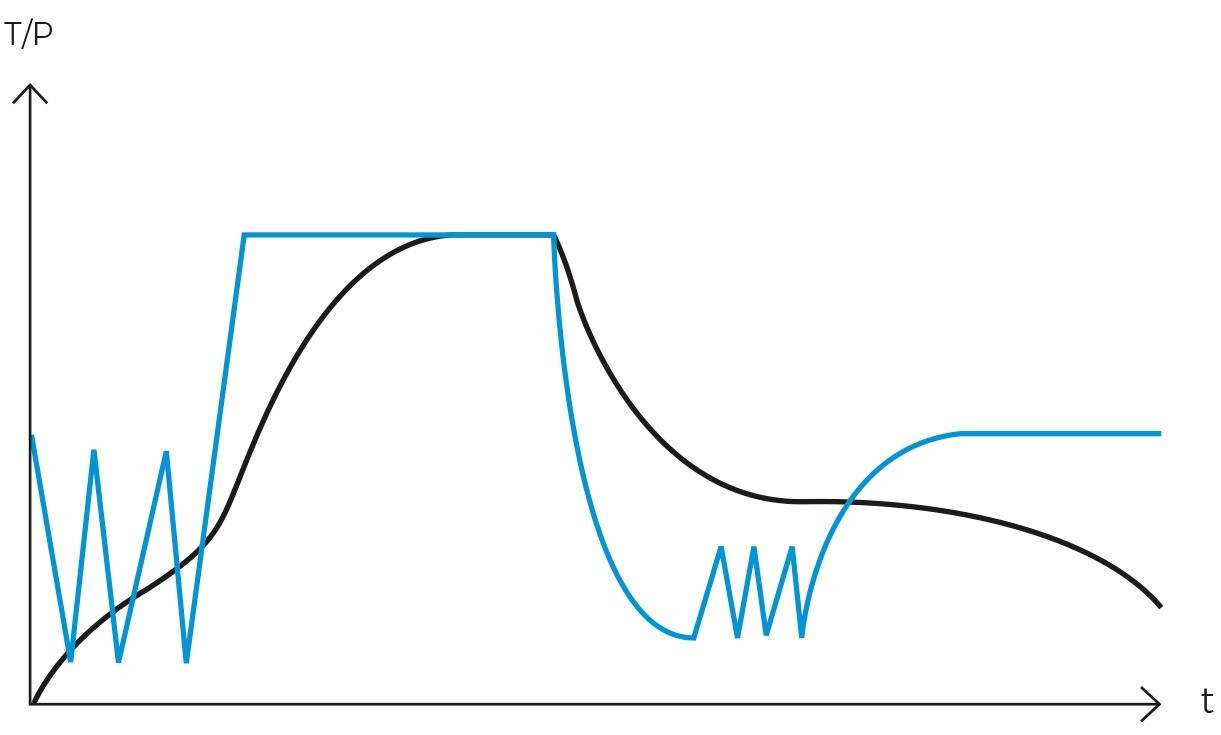

In the operation of the prevacuum cycle, the initial evacuation of air via a vacuum pump is essential to prevent trapped air from impeding steam penetration. Following this evacuation, saturated steam is introduced into the chamber, effectively penetrating all surfaces, including the internal parts of hollow or porous objects, due to the absence of cold air pockets.

The active removal of air through vacuum pulses is a key feature of the prevacuum cycle, enabling more effective steam penetration compared to the gravity cycle. While the gravity cycle relies on passive displacement of air by steam, the prevacuum cycle ensures that even the smallest and most complex spaces are accessible to steam.

The penetration of steam is crucial for successful sterilization, as it allows the steam to come into contact with all surfaces, including the internal parts of medical and dental instruments with narrow lumens or porous materials. The high temperature and pressure of the steam in the prevacuum cycle ensure the effective destruction of any microorganisms.

The prevacuum cycle is distinguished by its precise control and monitoring of all critical parameters, such as temperature and pressure, which are fundamental for achieving optimal conditions that promote sterilization. Modern autoclaves equipped with this cycle incorporate automated control systems, which not only record and adjust these parameters but also ensure the reproducibility and efficacy of the process regardless of the type of load.

Advantages of the prevacuum cycle over the gravity cycle in autoclaves

The prevacuum cycle, compared to the gravity cycle, offers significant advantages in efficiency, effectiveness, and versatility. These features are particularly valuable in environments where sterility is critical, such as hospitals, research laboratories and the pharmaceutical industry. The superior steam penetration combined with the absence of non-condensable gases in the chamber ensures that porous loads, bagged items, and objects with complex geometries are processed with excellent homogeneity and precision, thereby reducing the risk of sterilization failure.

Superior steam penetration

One of the main advantages of the prevacuum cycle over the gravity cycle is its ability to achieve more effective and uniform steam penetration. This is achieved by mechanically removing air from the sterilization chamber prior to the introduction of steam, ensuring that there are no pockets of cold air to act as an insulating barrier.

This occurs because air contains non-condensable gases, and the presence of these gases prevents the condensation of steam on the surfaces of the load, impairing the correct heat transfer from the steam. This capability is particularly crucial for sterilizing objects with complex internal surfaces and geometries, such as surgical instruments with lumens and cavities, or porous materials like textiles.

Increased speed

Vacuum cycles accelerate the heating phase, making them valuable for rapid sterilization when time is critical. Instead of relying on gravity to slowly and inefficiently remove cold air, vacuum cycles enhance efficiency by actively extracting the air from the chamber.

This process involves prevacuum autoclaves, which use a vacuum pump to remove air from the chamber through multiple vacuum pulses, expelling the air outside.

Effectiveness with porous and complex loads

The prevacuum sterilization cycle is the recommended sterilization cycle for porous loads, such as surgical textiles, wrapped instrument kits, and other materials that can trap air. Efficient air removal ensures that saturated steam fully penetrates these materials. In contrast, the gravity cycle does not effectively remove air, increasing the risk of unsterilized areas due to air pockets.

Reduction in the risks of sterilization failure

The prevacuum cycle significantly reduces the risk of sterilization failures. By more effectively controlling air removal and steam distribution, it minimizes the likelihood of load surfaces remaining unsterilized. Additionally, modern autoclaves with prevacuum cycles are equipped with microprocessors that monitor multiple sensors and constantly execute automated controls over all critical process parameters, providing greater reliability and consistency compared to autoclaves that only perform gravity cycles.

Versatility in a wider range of applications

The prevacuum cycle is more versatile and suitable for a wider range of applications. While the gravity cycle is effective for simple and non-porous loads, the prevacuum cycle can handle a variety of loads, including complex medical instruments, laboratory equipment, and sensitive materials. This versatility makes it indispensable in environments where different types of loads requiring sterilization are managed.

Specific applications of the prevacuum sterilization cycle in autoclaves

The prevacuum cycle in autoclaves is essential across various sectors where effective and reliable sterilization is required. Its adaptability to different applications makes it indispensable in dental, veterinary, and medical industries, as well as in the pharmaceutical industry and research environments.

In medicine and dentistry, the prevacuum cycle is crucial for sterilizing instruments with narrow lumens and complex cavities, ensuring complete steam penetration to prevent cross-infections. This capability is equally important for medical equipment such as endoscopes, catheters, textiles, and implants, where thorough sterilization is necessary to ensure patient safety.

In the pharmaceutical industry and research laboratories, the prevacuum cycle is used to sterilize bulk products and sensitive materials, ensuring the integrity of culture media, solutions in ampoules, and laboratory equipment. Its reliability is vital to prevent contamination that could compromise experimental results.

Implementation of the prevacuum sterilization cycle in practice

The effective implementation of the prevacuum cycle in autoclaves demands meticulous attention to technical and operational details to ensure safe and efficient sterilization. Key aspects include:

1. Autoclave configuration

Ensuring the autoclave is correctly configured is crucial. This involves initial qualification of the equipment after installation, periodic calibration, and both preventive and corrective maintenance. Modern autoclaves with digital interfaces facilitate the configuration and monitoring of these parameters both onsite and remotely. Maintaining the autoclave in optimal condition through regular maintenance and performance checks is essential.

2. Load preparation

Items must be thoroughly cleaned and, if necessary, properly wrapped or packaged. The arrangement of the load should allow for optimal steam circulation and effective air removal, avoiding overly tight or overlapping packages that might obstruct steam penetration. Additionally, baskets should not be overloaded. When stacking multiple baskets, ensure that the base of the upper basket does not touch the materials in the lower basket.

It is also important to use specific accessories recommended by the manufacturer and to avoid placing objects in direct contact with the chamber walls.

3. Operation of the prevacuum cycle

The number of vacuum pulses, cycle duration, and settings for temperature and pressure should be customized for each specific type of load. Autoclaves typically come with pre-programmed cycles designed for various materials and applications. When in doubt, it is advisable to contact the manufacturer. As a general recommendation, always opt for a more thorough program and avoid using flash cycles.

4. Monitoring and validation

Continuous monitoring is vital to maintain appropriate sterilization conditions. Sensors and automated logging systems help track critical parameters such as temperature, pressure, and time. Regular validation of the sterilization process, using biological and chemical indicators, is essential to confirm the efficacy of the prevacuum cycle.

5. Maintenance and troubleshooting

Regular maintenance of the autoclave is crucial for its optimal operation. This maintenance includes cleaning the chamber, verifying the proper functioning of valves, and maintaining all autoclave components. Additionally, routine functional tests, such as the vacuum leak test or the Bowie-Dick test, should be performed to confirm the autoclave’s proper operation. Promptly addressing any signs of malfunction will ensure the autoclave continues to operate effectively.

Challenges and recommendations while performing prevacuum cycle in autoclaves

The prevacuum cycle in autoclaves, despite being an effective and widely used technique, faces challenges that require specific solutions to maintain its efficiency and effectiveness, especially due to the use of more advanced autoclaves that incorporate a greater number of components.

- Handling special loads: The sterilization of complex surgical instruments, porous materials, and devices with narrow lumens presents unique challenges. Recommendations for processing these items include using proper loading techniques that facilitate air removal and steam penetration, selecting appropriate sterilization programs, and conducting frequent steam penetration tests such as the Bowie & Dick test.

- Operational efficiency: Maintaining high operational efficiency, particularly in environments with intensive autoclave usage, necessitates the automation of processes and the establishment of clear protocols for each type of load, as well as the definition of specific programs for the most frequent applications. Furthermore, training personnel in the efficient use of the autoclave is crucial to enhancing productivity.

- Parameter control and monitoring: Precise control and constant monitoring of parameters such as temperature, pressure, and time are crucial. Analyzing these results helps detect problems related to loss of effectiveness. Autoclaves with advanced control systems and accurate sensors facilitate the adjustment and monitoring of these parameters; some even automatically adjust cycles based on load variations or operating conditions.

- Maintenance and troubleshooting: Inadequate maintenance can lead to sterilization failures and downtime. It is essential to implement a regular preventive maintenance program and train personnel in identifying and resolving common issues. Additionally, having a reliable and responsive technical support service is crucial for effectively addressing breakdowns.

- Compliance with regulations and standards: Complying with the constantly evolving sterilization regulations and standards is a challenge. Staying updated with the latest regulations and ensuring that equipment and processes meet these standards is vital. Collaborating with regulatory agencies and participating in training sessions and seminars are effective strategies to stay current.