The cycle with drying

Learn how autoclaves equipped with cycles with drying enhance sterilization efficacy and mitigate the risk of recontamination. Read this article to understand all their features.

Steam autoclaving is a fundamental technique in fields such as medicine, microbiology, and the food industry, where the thorough eradication of microorganisms and pathogens from pharmaceuticals, test specimens, and food products is imperative. This objective is achieved through the use of an autoclave, which sterilizes equipment, instruments, and objects by employing steam at elevated pressure and temperature.

A critical component of this process is the cycle with drying, which ensures the effectiveness and safety of sterilization across all types of solid objects. This cycle facilitates the complete removal of moisture from the load prior to the conclusion of the sterilization process. In the following article, we will explain everything you need to know about this type of cycle.

What is an autoclave with drying?

An autoclave with drying is a specialized sterilizer that not only performs the conventional steam sterilization process but also incorporates a drying phase at the end of the cycle.

This drying phase is critical for eliminating any residual moisture from the sterilized objects. Residual moisture can serve as a breeding ground for microorganisms, thereby posing a significant risk for contamination and potentially compromising the sterility of instruments and materials. The inclusion of the drying phase ensures that the sterilized items remain free from moisture, thereby maintaining their sterile state.

Operation of the cycle with drying

The sterilization cycle in an autoclave with drying consists of several steps:

-

Purge phase

Before sterilization, it is imperative to remove all air from the autoclave, as air can act as an insulator and prevent the steam from reaching the necessary temperature for effective sterilization. To achieve this, autoclaves with drying use a vacuum pump that mechanically expels this air.

-

Heating phase

At the end of the purge phase, the autoclave generates steam and the temperature inside the chamber rises progressively until the sterilization temperature is reached.

-

Sterilization phase

During this phase, the high-pressure steam destroys any microorganisms or spores present in the load, ensuring complete sterilization.

-

Drying phase

Following the sterilization phase, the autoclave enters the drying phase. Here, heat or a combination of heat and vacuum is employed to evaporate any residual moisture from the chamber and the sterilized items. Typically, a heating jacket is used to warm the walls of the chamber and the load, while a vacuum pump expels all moisture to the outside. Proper completion of this phase is essential to prevent recontamination of solid objects once they are removed from the autoclave.

-

Cooling phase

After drying, the autoclave starts the cooling phase, reducing the temperature and pressure of the chamber to 80ºC.

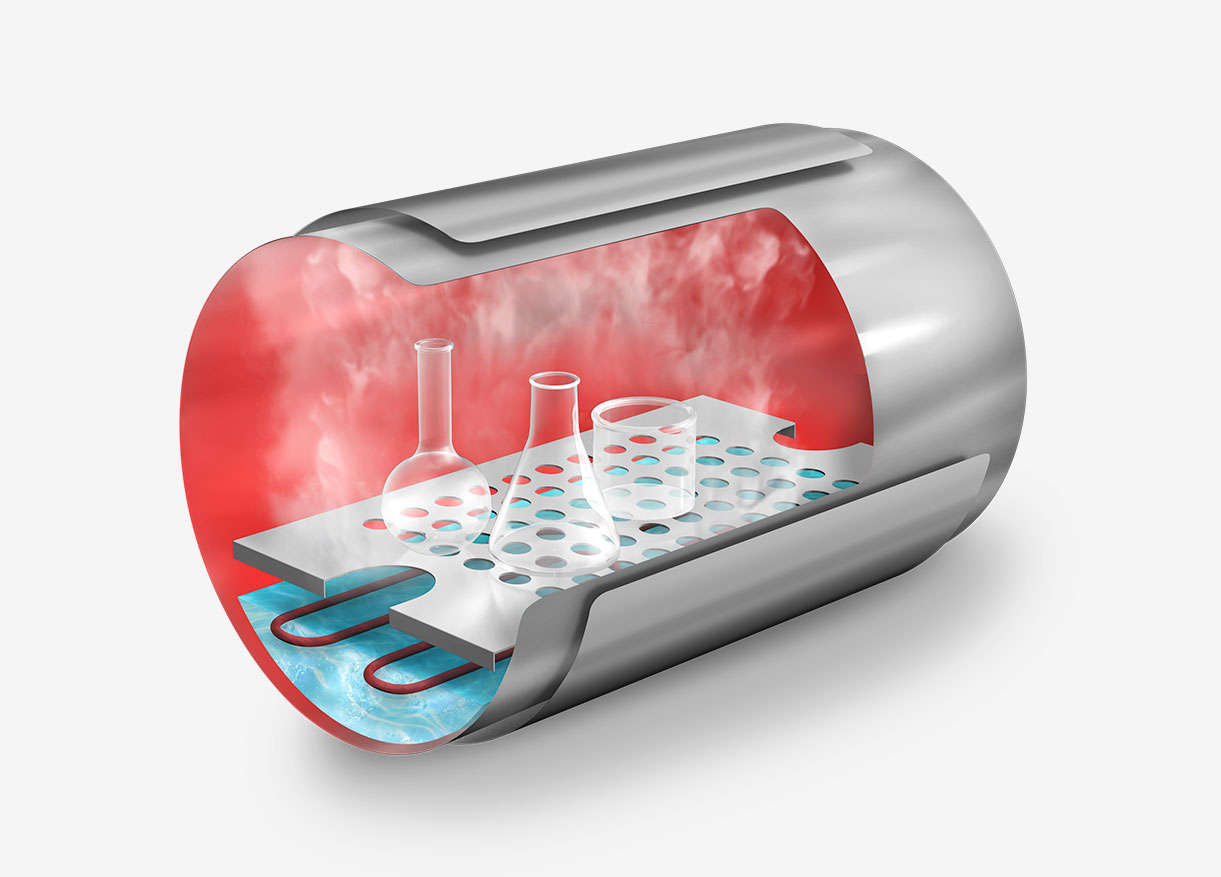

The accompanying image illustrates the operation of an AHS-DRY Series autoclave during the drying phase. These models are equipped with electric heating elements and an integrated water tank. During the cooling phase, the water automatically returns to the tank. Upon starting the drying phase, the heating jacket surrounding the sterilization chamber is activated, and simultaneously, the vacuum pump expels the humid air to the outside.

The importance of drying in sterilization

The drying phase in the autoclave sterilization process is often underestimated, yet its importance is fundamental to ensuring the safety and efficacy of sterilization procedures.

Prevention of post-sterilization contamination

One of the most significant risks associated with insufficient removal of moisture from the load is the possibility of post-sterilization contamination. Residual moisture on sterilized items can act as a reservoir for microorganisms to regrow on sterilized materials. This phenomenon, known as capillarity, occurs when moist objects come into contact with contaminated environments, surfaces, or hands, allowing microorganisms to migrate through the moisture into the object. Therefore, proper drying is essential to maintain the sterility of the instruments until they are used.

Maintaining the integrity of materials

Residual moisture can cause corrosion on metal instruments and deterioration of other sensitive materials. For instance, laboratory instruments can undergo physical changes if stored wet, affecting their functionality and shelf life. Additionally, moisture can compromise the strength of packaging materials, potentially leading to package rupture and exposure of the contents to external contamination.

Effect on efficacy and safety

Complete and effective drying is vital to ensure that sterilized materials are safe for use. In clinical and laboratory settings, where sterility is of paramount importance, failure to ensure adequate drying can have serious consequences, including nosocomial infections. Proper drying ensures that sterilized items remain free from contamination until they are used, thereby maintaining their safety and efficacy.

Factors influencing the drying process in an autoclave

The drying process in an autoclave is influenced by multiple factors that can impact its efficacy. Understanding these factors is essential for optimizing the drying process and ensuring effective and safe sterilization.

-

Autoclave type: Dynamic air removal vs. gravity displacement

Autoclaves that utilize dynamic air removal, which eliminate air using a vacuum pump before introducing steam, facilitate a more uniform and efficient drying process. In contrast, autoclaves relying on gravity displacement depend on gravity to purge the air and are less efficient in drying, particularly for bulky loads or large packages.

-

Autoclave configuration and loading

Excessive loading or improper arrangement of items can hinder the free circulation of air and steam, resulting in uneven drying. It is crucial to follow the manufacturer’s recommendations regarding maximum capacity and proper arrangement of materials within the autoclave.

-

Type and weight of materials

Denser materials or those with greater mass can retain more moisture and require longer drying times. The type of wrapping or container used also affects drying efficiency. Depending on the type of load, the drying phase must be programmed for a shorter or longer duration.

-

Quality of steam

Pure, high-quality saturated steam facilitates a more efficient subsequent drying process. Conversely, low-quality, more mineralized steam can increase residual moisture in sterilized materials by transferring mineral salts to the load, causing obstructions and increasing the hygroscopicity of the load.

-

Environmental conditions

The environmental conditions of the area where the autoclave is located, such as altitude, external temperature, and humidity, can affect the drying process. A more humid or colder environment may prolong the drying times required to fully dry the load. Additionally, locations above 1000 meters above sea level will require specific adjustments to operate correctly.

Procedures and best practices for effective drying

Implementing appropriate protocols and adhering to best practices are essential steps to achieve optimal drying in the autoclave sterilization process.

-

Adherence to manufacturer instructions

It is crucial to meticulously follow the specifications and recommendations provided by the autoclave manufacturer, particularly regarding the cycles with drying. This includes the cycle duration, the recommended drying temperature, and specific instructions for various types of loads. Modern autoclaves often allow for adjustments in the duration and temperature of the drying phase. However, it must be understood that the drying cycle is specifically designed to process solid objects.

-

Proper loading of the autoclave

Avoid overloading the autoclave and ensure an even distribution of items to facilitate the circulation of air and steam. When stacking baskets, ensure the bottom of the upper basket does not touch the materials in the lower basket. Proper arrangement is critical for both effective sterilization and complete drying.

-

Appropriate use of wrappers and containers

Select suitable wrappers and containers for the materials to be sterilized. Ensure they allow for the free exit of moisture.

-

Monitoring and adjusting drying cycles

Monitor the results of the drying cycles and adjust the duration or temperature of the drying phase as necessary. Tailoring the process to the specific needs of the load will enhance drying efficiency.

-

Regular maintenance of the autoclave

Regular and proper maintenance is essential to ensure optimal operation. This includes routine cleaning, inspection of critical components, and calibration of probes.

-

Consideration of the work environment

The environment in which the autoclave is located can influence the drying process. Avoid placing the autoclave in areas with high humidity or temperature fluctuations. Adjustments to the autoclave may be necessary for locations above 1000 meters above sea level.

Incident management during the drying cycle

Despite the implementation of best practices and procedures, incidents may occur during the drying cycle in an autoclave. It is essential to manage these incidents effectively to maintain the integrity of sterilization and the safety of the materials.

-

Identification and response to interruptions

In the event of an interruption during the drying cycle, promptly identify the cause, whether it be a power outage, mechanical failure, or human error. The appropriate response depends on the duration and nature of the interruption. If the interruption is brief, the cycle may be resumed with minimal impact; however, if it is prolonged, it is necessary to repeat the entire sterilization cycle.

-

Residual moisture evaluation

Following any incident, inspect the materials for residual moisture. If moisture is detected, it is advisable to re-sterilize the materials. It is also recommended to visually inspect the load after each cycle and verify that no moisture or water remains in the load upon completion of the cycle.

-

Documentation and reporting of incidents

Document incidents in detail, including their nature and the corrective actions taken. This documentation is important for presentation to the maintenance technician during the annual equipment inspection.

-

Review and adjustment of procedures

After an incident, review and adjust the operational procedures for autoclave use, and if necessary, also the program parameters, to prevent future incidents. This may include reviewing autoclave maintenance protocols and training the personnel operating the equipment.

-

Staff training and awareness

Personnel operating the autoclave should receive adequate training on the importance of the drying cycle, the types of loads compatible with it, how to organize the load within the autoclave, and how to handle incidents. Continuous training will help reduce the likelihood of failures.

Maintenance and care of the autoclave to optimize the drying process

Proper maintenance and care of the autoclave are essential to optimize the drying process and ensure overall sterilization efficiency.

-

Regular preventive maintenance

Preventive maintenance is crucial for the optimal functioning of the autoclave. This includes the regular inspection of critical components such as lid seals, valves, sensors, and control systems. Preventive maintenance helps identify and resolve issues before they develop into major failures, which can affect drying and sterilization efficiency.

-

Cleaning and disinfection

Regular cleaning is essential to keep the autoclave in optimal condition. The accumulation of residues or mineral deposits can impact the equipment’s efficiency, including its drying capability. The autoclave chamber, baskets, trays, and racks should be cleaned according to the manufacturer’s recommendations using appropriate cleaning agents.

-

Ongoing staff training

Personnel responsible for operating and maintaining the autoclave should receive continuous training. This ensures they are aware of the best maintenance and care practices and can operate the equipment safely and efficiently.

-

Verification and calibration of sensors and controls

The autoclave’s sensors and controls should be regularly verified and calibrated to ensure proper functionality. Incorrect calibration can lead to inefficient drying cycles, affecting sterilization quality. Regular calibration ensures that cycle parameters such as temperature and pressure are accurate.

-

Vacuum systems and steam quality check

Since the vacuum system and steam quality are critical factors in the drying process, it is important to review and maintain the vacuum and steam generation systems. This includes ensuring that the autoclave generates steam of the appropriate quality and that the vacuum pump operates efficiently.

-

Seal inspection

Autoclave seals should be regularly inspected for signs of wear or damage. A defective seal can allow steam to escape, affecting drying efficiency. Replacing worn seals is essential to maintain hermeticity and an efficient sterilization environment.