Accelerated aging cycle: the key to product life cycle assessment

Discover how the accelerated aging cycle makes it possible to evaluate the service life of products by subjecting them to extreme conditions.

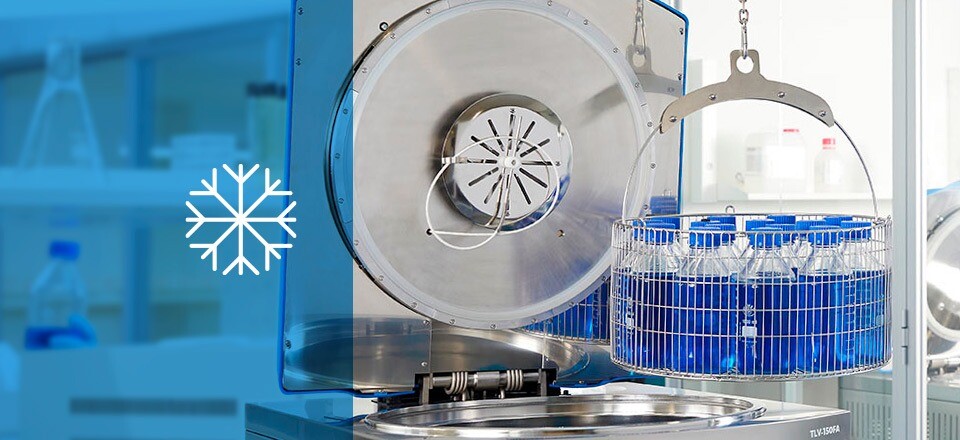

The accelerated aging cycle in autoclaves constitutes a technique employed in specialized research and quality control laboratories across various sectors, including the electronics, construction, medical devices and packaging industries. This method is essential for validating the structural and functional integrity of novel materials.

In contrast to conventional sterilization methods, the accelerated aging cycle is characterized by the implementation of multiple consecutive sterilization cycles conducted continuously within a sealed chamber. This process is designed to subject products to exceptional stress levels, with the objective of thoroughly investigating their durability and response to extreme conditions.

Overview of the process

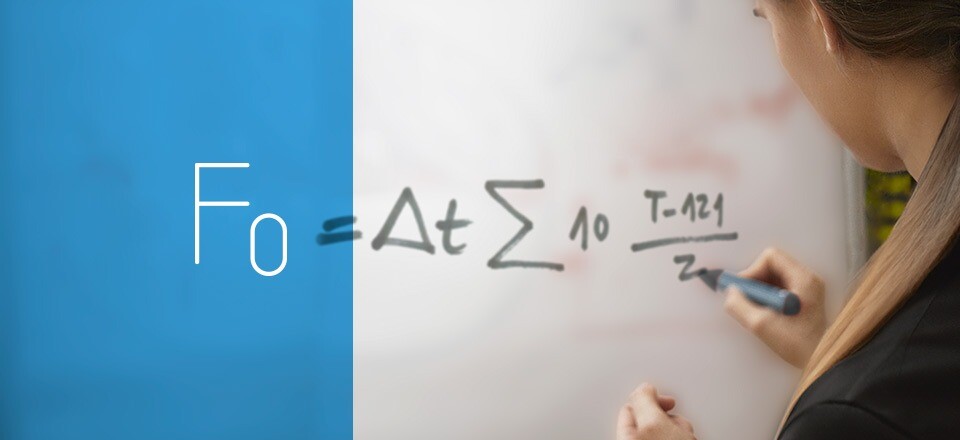

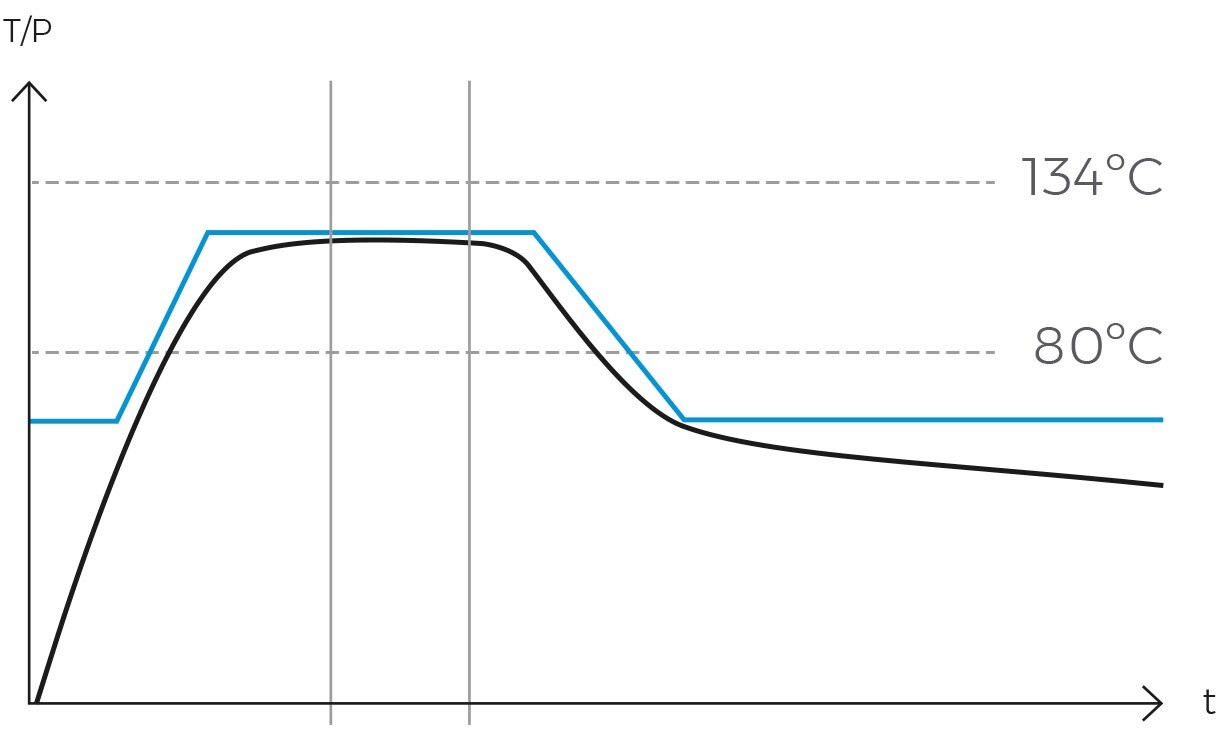

The cycle commences with the placement of the product into the sterilization chamber, where it is subjected to a series of repetitive sterilization cycles without interruption. These cycles can be maintained uniformly or vary in duration, with maximum temperatures that may either progressively increase or decrease. While conventional applications typically do not necessitate extremely high temperatures, these tests are commonly conducted within a range of 80°C to 134°C.

The objective of this methodology is to simulate the effects of time and adverse conditions that the product may encounter throughout its lifecycle, but within a significantly shortened timeframe. This approach facilitates an accurate and efficient assessment of the durability and reliability of the materials and products under study.

Industrial applications of accelerated aging tests with autoclave

Lifecycle testing cycles using autoclaves hold significant relevance in the development of new materials and products. Below, we explore how this methodology is applied across various industries.

In the electronics industry, the use of this cycle is essential for predicting and ensuring the resilience of electronic components under continuous use. These tests simulate the operational conditions these components may face throughout their service life or during manufacturing, allowing for the anticipation of potential failures and ensuring optimal performance over their lifespan.

Within the construction sector, the accelerated aging sterilization cycle is employed to evaluate the durability and resistance of construction materials under scenarios of artificially accelerated wear and aging. This is crucial to ensure that materials maintain their structural and functional integrity, meeting the required safety standards for buildings and structures.

In the packaging industry, the application of this cycle serves to verify the durability and protective capacity of packaging after being subjected to a standard sterilization process during its useful life. This analysis ensures that packaging will maintain the product’s integrity and protect its contents effectively until it reaches the final consumer.

In the pharmaceutical sector, the importance of these sterilization cycles is even greater, as they are fundamental in determining the shelf life and expiration dates of pharmaceutical products. Simulating stress conditions helps predict the behavior of medications during manufacture and during storage, ensuring their efficacy and safety for patients.

Autoclaves for conducted accelerated aging studies and product lifecycle tests

Before utilizing an autoclave for these purposes, it is essential to ensure that the equipment is equipped with the appropriate technology, pertinent components, and necessary robustness to withstand the stress conditions of these test cycles. The selection of an autoclave should be based on a detailed evaluation of its construction quality, the manufacturer’s reputation, and its durability to endure the demanding test cycles simulating accelerated stress conditions.

To ensure that the autoclave meets these standards, it is advisable to contact the manufacturer directly. Typically, autoclave manufacturers do not design their equipment specifically for conducting accelerated aging tests or lifecycle testing. The intensity of the test cycles requires the use of high-quality materials and components, which can significantly increase production costs.

If you already have an autoclave, a key indicator of its suitability for these tests is its capability to configure custom programs that can execute these accelerated aging cycles repetitively and continuously

If you require an autoclave designed to carry out accelerated aging and product lifecycle tests, we can custom-build it to meet your exact specifications and requirements. Contact us for more information.