Autoclaves > Classic line verticals AE-DRY-MD Series

Vertical medical autoclaves with drying

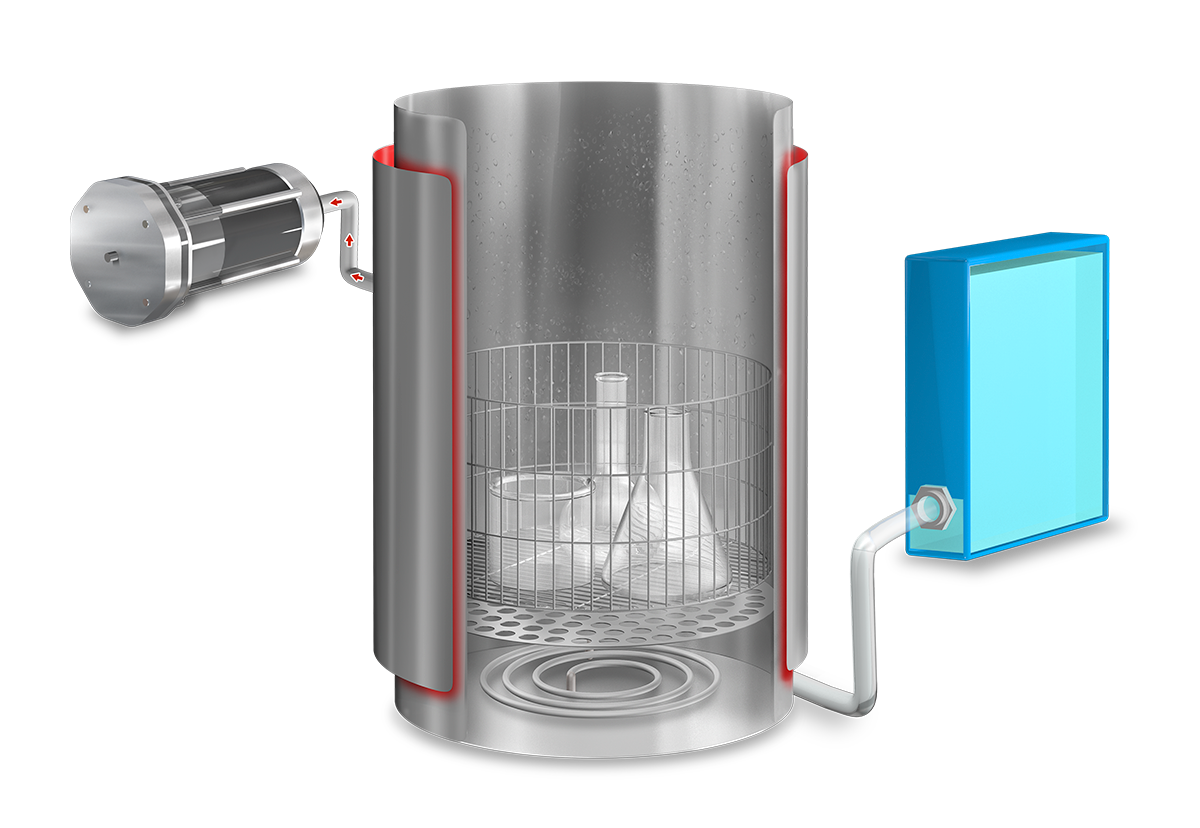

The AE-DRY-MD Series vertical medical autoclaves with drying are specifically designed for sterilizing solid loads and enhancing productivity in healthcare facilities.

- Solid loads are completely dry upon cycle completion

- Economical, cost-effective, and with robust performance

- Excellent construction materials

Vertical medical autoclaves with drying

The AE-DRY-MD Series vertical medical autoclaves meet the sterilization needs of clinical, healthcare and research facilities with the aim of boosting productivity and reducing each sterilization cycle’s turnaround time. There is no need to dry the load in an external oven.

Designed for sterilizing bagged solid loads, porous and hollow objects, glass, plastics, metal utensils, and laboratory waste bags. They can also process liquids and culture media.

The versatility to process all types of loads, the final drying function, and the highest degree of automation, along with greater efficiency in resource consumption such as water, energy, and operational time, result in a cost-efficient solution for managing the laboratory’s workload.

Save time thanks to the final drying function

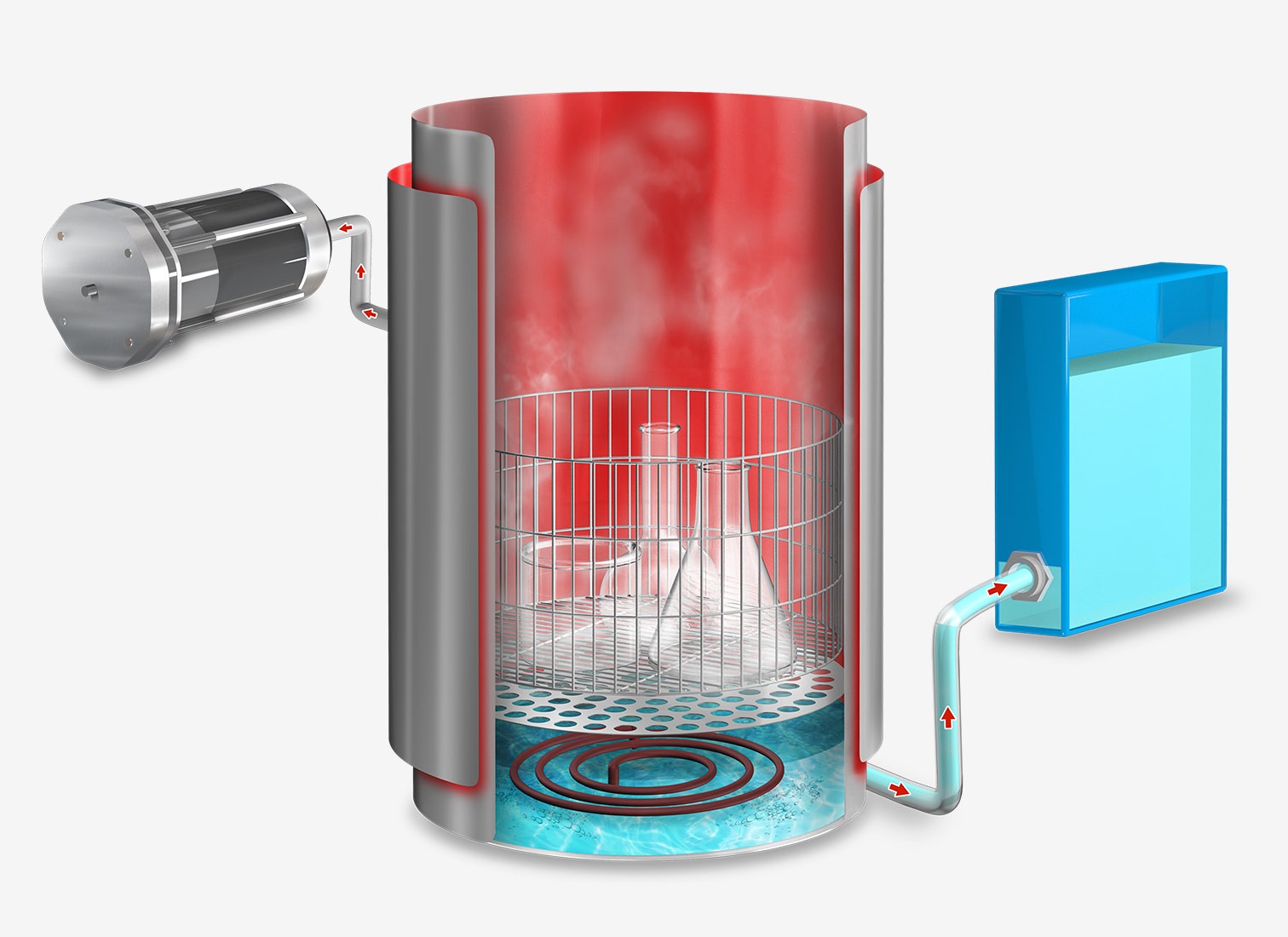

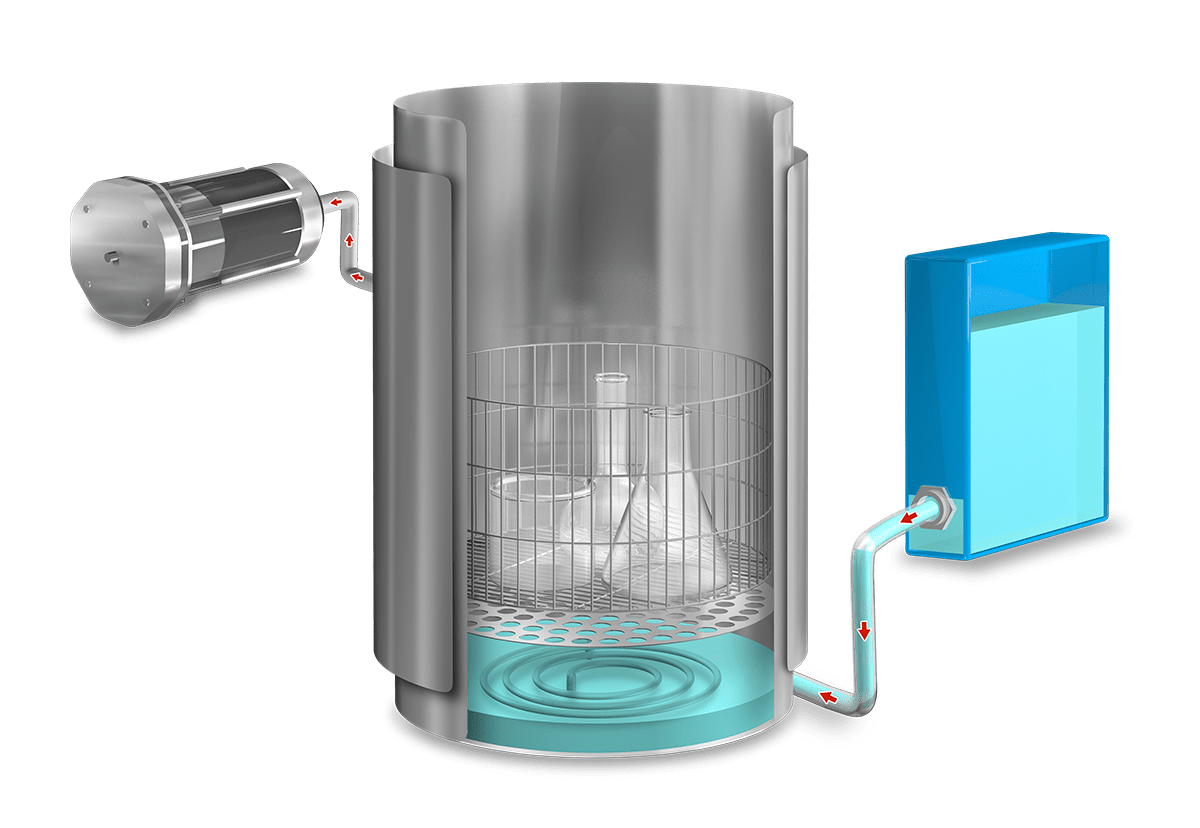

Thanks to its final drying function using a heating jacket and vacuum pump, the load will be completely dry at the end of the cycle, eliminating the need to dry the load in an external oven, thus gaining convenience and saving handling time.

Optimized sterilizations and higher degree of automation

Mechanical purge through a vacuum pump to remove air pockets and improve steam penetration. Specific programs for liquids. Includes a bacteriological filter and an independent water tank that can be equipped with an automatic filling kit for seamless operation.

Customize with a range of accessories

Choose the baskets and crane that best fit your needs. Install a flexible probe for more accurate and safe sterilization of liquids. Record and analyze your processes with dedicated software or an embedded printer. You can also enhance the heating capacity of your unit to save time.

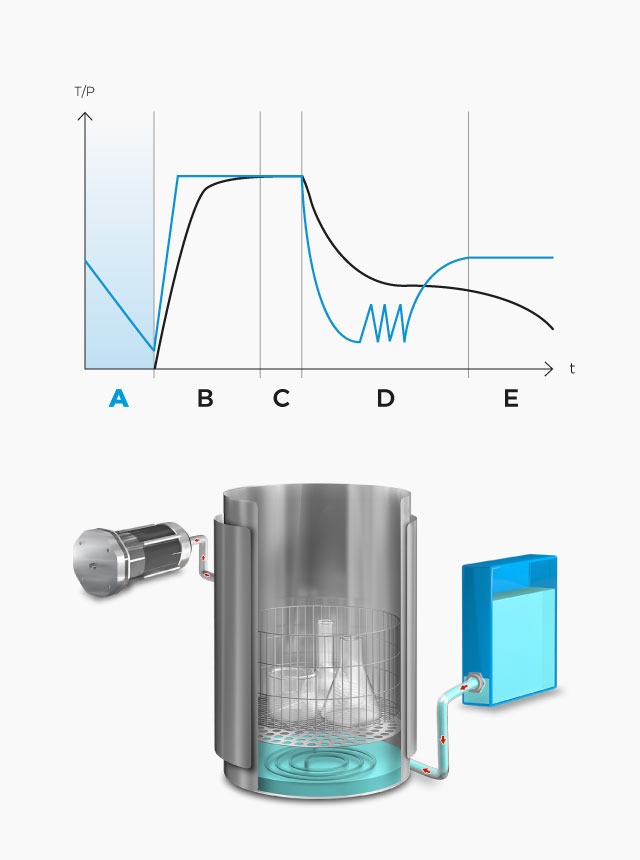

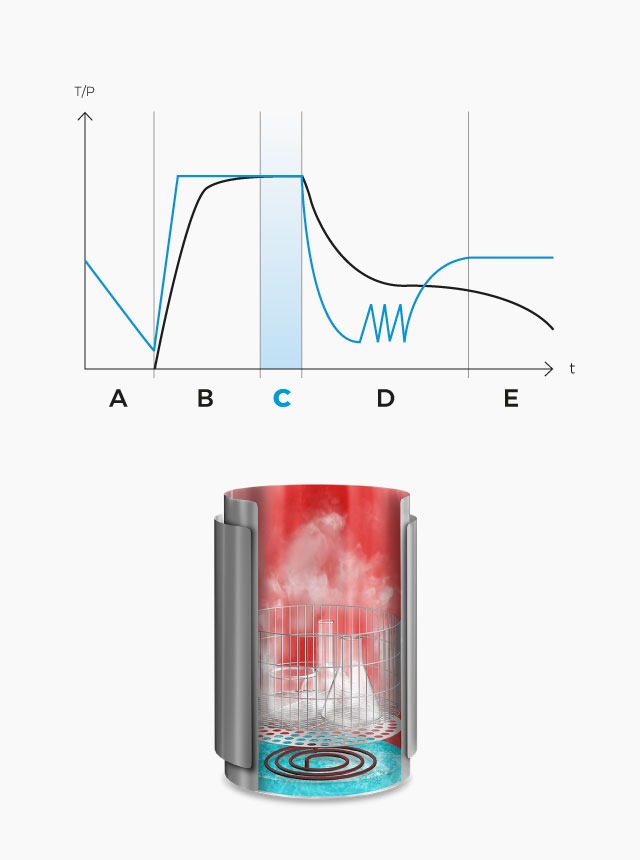

Operation

Temperature

Pressure

Operation

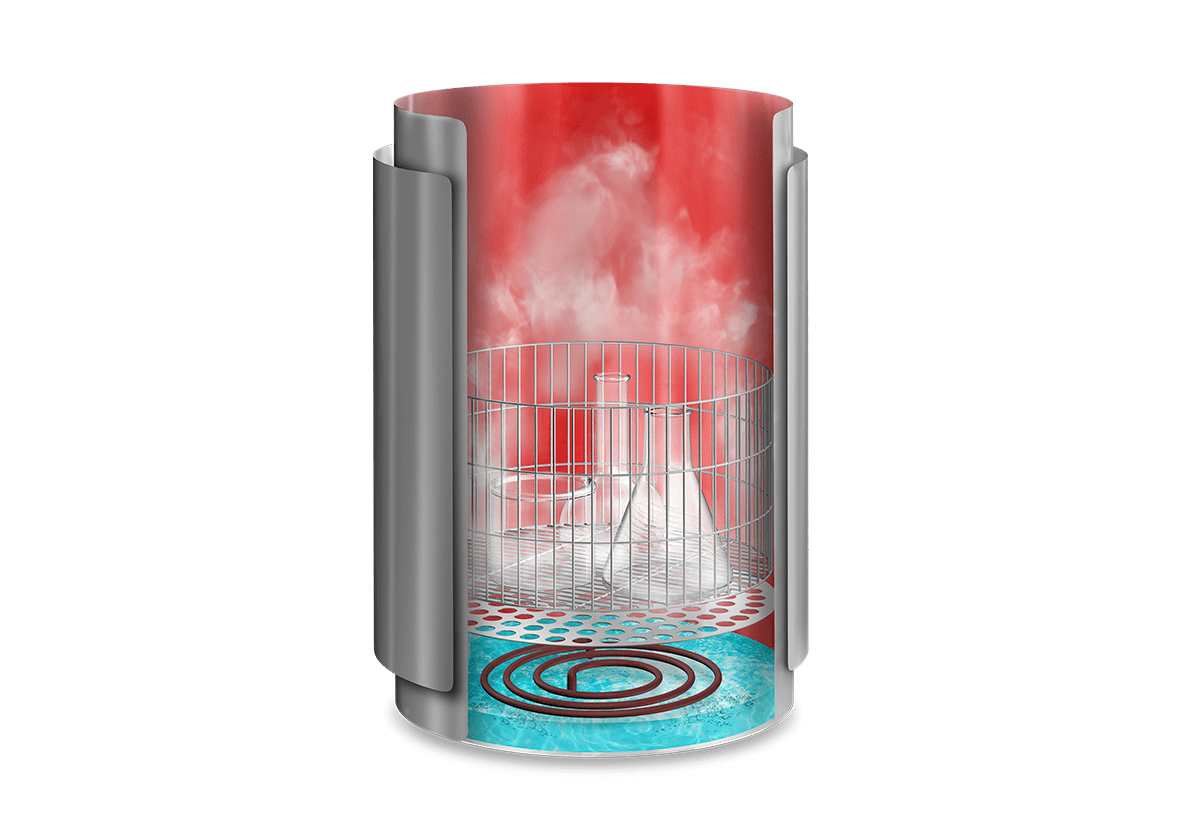

The cold air in the chamber is mechanically purged to the outside through a vacuum pulse, reducing the presence of non-condensable gases and facilitating steam penetration throughout the load.

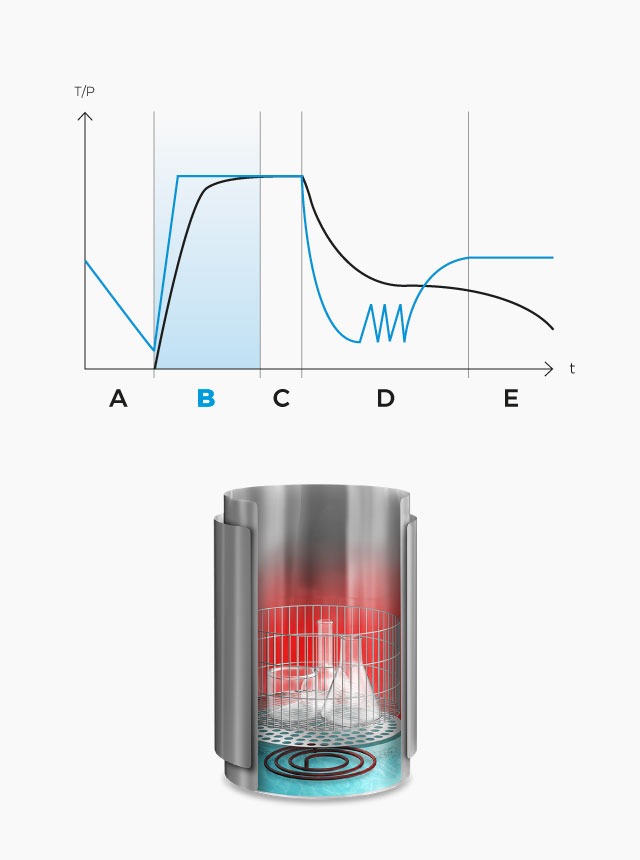

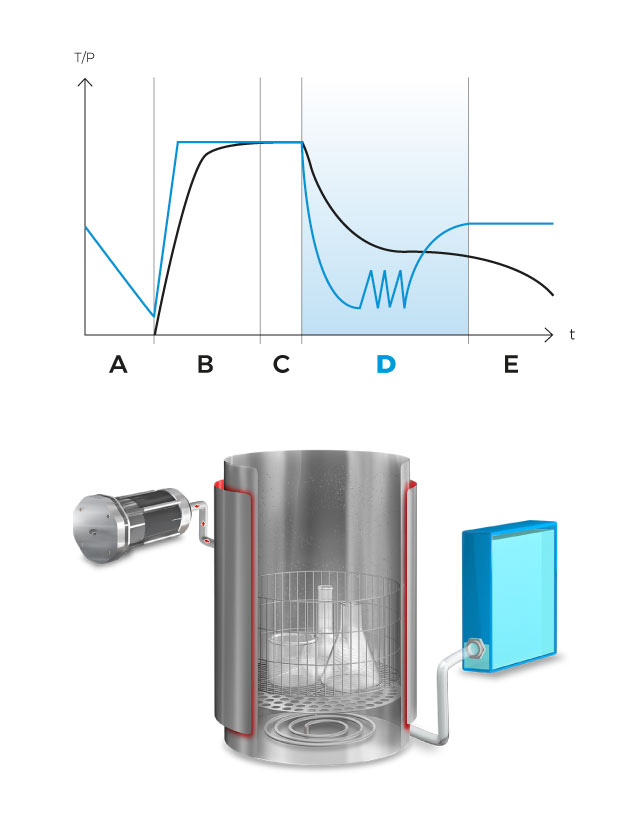

Temperature

Pressure

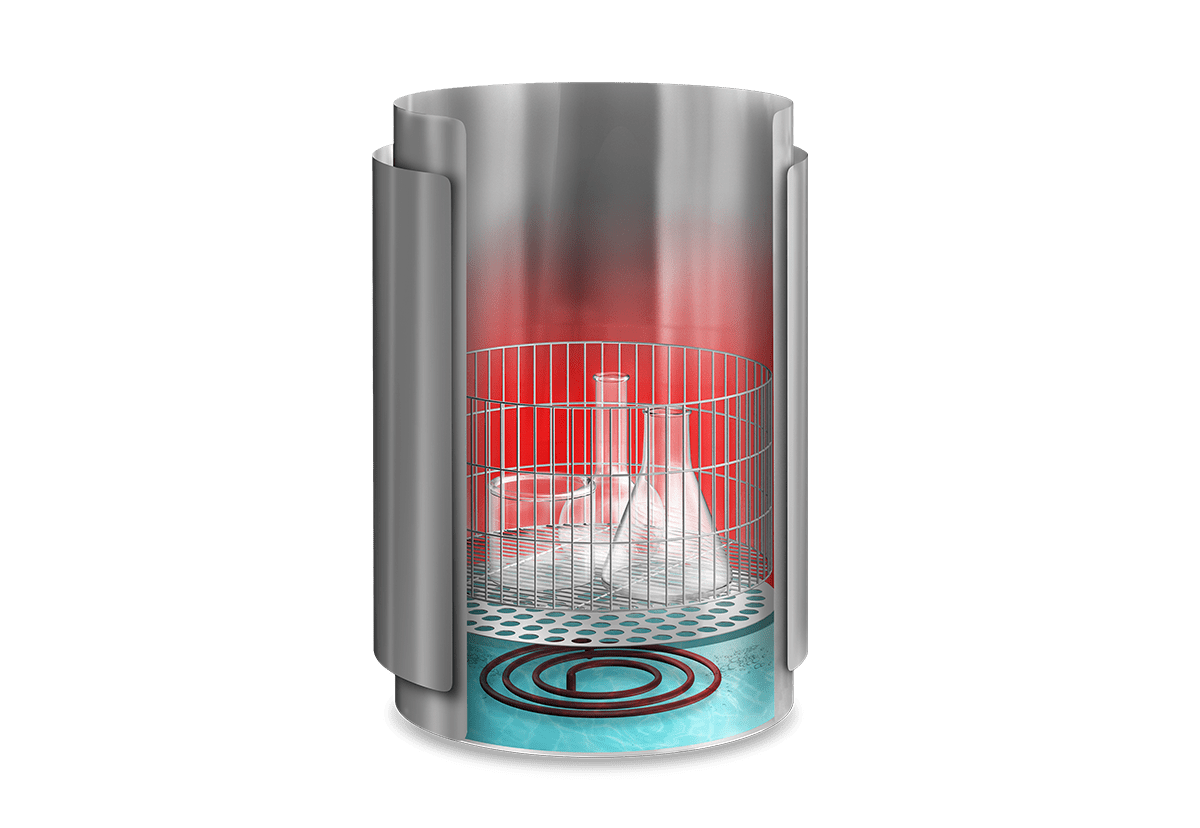

After completing the first vacuum pulse, the heating elements heat up water to produce saturated steam, which expels the cold air outward until the sterilization temperature is reached in the chamber.

Temperature

Pressure

Upon reaching the sterilization temperature in the medium, the sterilization phase begins and the temperature is accurately sustained for the predefined duration. Antibiotics, pH correctors or thermolabile ingredients can be dispensed at any time using the external dispensing ports.

Temperature

Pressure

In programs for solid loads, after the sterilization phase is completed, the vacuum pump and heating jacket are activated simultaneously to expel all moisture and completely dry the load through the use of multiple vacuum pulses. Conversely, in programs for liquid loads, this drying phase is not performed.

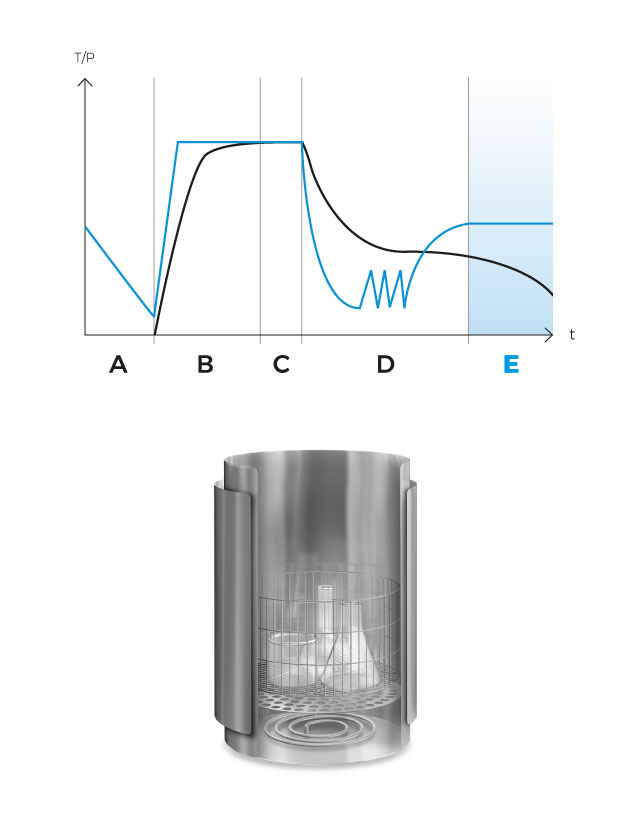

Temperature

Pressure

After the load is fully dry, a natural cooling phase begins, ending once the temperature drops to a level that's safe for handling the load without burning oneself. Then, the door can be unlocked, and the load can be taken out. Optionally, the agar mode can be configured to maintain a constant temperature.

Temperature

Pressure

Applications

POROUS SOLIDS AND WRAPPED OBJECTS

The initial pre-vacuum pulse facilitates steam access to porous loads and wrapped objects, enabling sterilization of high-complexity loads. They will also be dry thanks to the final vacuum drying function.

PLASTICS AND METAL OBJECTS

In programs for solid loads, the heating jacket and vacuum pump are activated at the end of the sterilization phase to completely dry the load.

GLASSWARE

In programs for solid loads, the heating jacket and vacuum pump are activated at the end of the sterilization phase to completely dry the load.

SANITARY WASTE

The mechanical purge of air using the vacuum pump facilitates the posterior penetration of steam, facilitating the sterilization of bagged items. Moreover, at the end of the cycle, they will be dry thanks to the drying function. Chemical and/or biological tests must be used to validate the proper sterilization of the load.

LIQUIDS AND CULTURE MEDIA

Specific programs for liquid loads. The agar mode maintains the temperature and prevents culture media from gelling. Installing a flexible probe allows for more precise sterilization of liquid loads.

Technical data

| References |

|---|

| Total/usable volume of the chamber (L) |

| Usable dimensions of the chamber (Ø x H mm) |

| External dimensions (L x D x H mm) |

| Loading height (mm) |

| Net weight (Kg) |

| Power (W) |

| Voltage* (V) |

| Frequency (Hz) |

| AE-28-DRY-MD |

| 33/31 |

| 300 x 440 |

| 505 x 580 x 1110 |

| 795 |

| 75 |

| 2000 or 3200 |

| 230 |

| 50/60 |

| AE-50-DRY-MD |

| 55/50 |

| 300 x 710 |

| 505 x 580 x 1290 |

| 975 |

| 95 |

| 3200 or 5000 |

| 230 |

| 50/60 |

| AE-75-DRY-MD |

| 79/75 |

| 400 x 600 |

| 610 x 700 x 1185 |

| 870 |

| 123 |

| 3200 or 6000 |

| 230 |

| 50/60 |

| AE-110-DRY-MD |

| 115/110 |

| 400 x 850 |

| 610 x 700 x 1435 |

| 1120 |

| 150 |

| 4500, 6000 or 9000 |

| 400 |

| 50/60 |

| AE-150-DRY-MD |

| 175/153 |

| 500 x 760 |

| 750 x 820 x 1400 |

| 1085 |

| 235 |

| 6000 or 9000 |

| 400 |

| 50/60 |

| *Other voltages and electrical configurations available on request. Special models with increased power may operate with other voltages. |

Accessories

Flexible probe

Add a flexible probe to improve the sterilization of liquid loads.

Integrated thermal printer

Prints program number, cycle number, temperature, date and hour of the run and error messages.

Automatic water filling kit

Water pump designed to automate the supply of the independent water tank with purified water.

Integrated basket lifting crane

Mobile crane integrated into the side of the autoclave, designed to assist in the loading and unloading of heavy items.

Mobile basket lifting crane

Crane with integrated battery, mobile and independent, designed to assist in the loading and unloading of heavy items.

Wire baskets

Baskets suitable for the sterilization of all types of clean loads.

Wire basket tray

Tray designed to be used in conjunction with wire baskets to collect liquids.

Unperforated baskets

Baskets suitable for sterilization of dirty loads and those at risk of spillage.

Schimmelbusch Drum

Drum suitable for sterilization of medical instruments and biohazardous loads.

Height adjustable tray support

For sterilization of instruments, small bags and other small objects that must be placed straight up.

Cylinders with basket

Suitable for sterilization of Petri dishes with a diameter of 80 or 120mm.

Standard cylinders

Suitable for sterilizing pipette tips and other small consumables.

External dot matrix printer

Prints program number, cycle number, temperature, date and hour of the run and error messages.

SW7000 Software

Communication software between the equipment and the PC for display and recording of each cycle.

Premium casters

Higher quality casters with brakes.

Transport trolley

Auxiliary trolley to aid in the loading and unloading of equipment and containers.

Eco-efficient water purifier

Eco-efficient direct-flow water purifier without water storage, capable of filtering 1.3L/min with an LED display.

Purified water tank

25L bottle for storing purified water

Cable gland

Cable gland allowing access for up to 8 probes for calibration and validation operations.

External temperature probe adapter

External adapter for continuous validation processes that allows obtaining a temperature reading independent of the equipment's microprocessor.

Temperature recorder

Disk-shaped datalogger for monitoring the temperature inside a load.

Sterilization control tape

Class 1 indicator for steam sterilization.

IQ-OQ Documentation

Delivery of documentation and IQ/OQ protocol for third party autoclave qualification.

IQ-OQ-PQ Qualification

IQ/OQ/PQ autoclave qualification service performed by RAYPA.

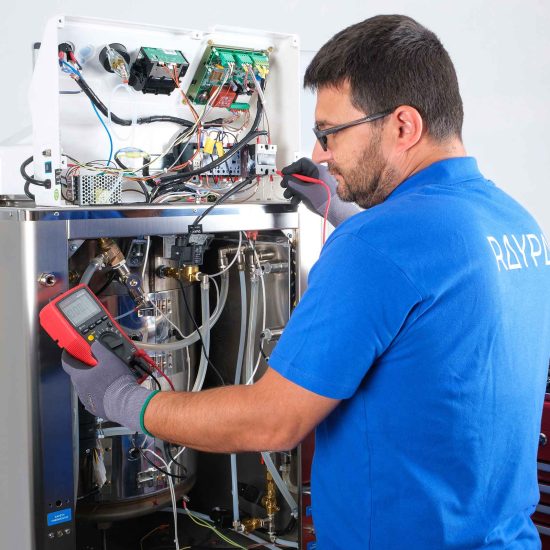

On-site commissioning & training

On-site guided start-up that includes the verification of the correct operation and installation of the equipment, complemented by a training session on its operation and maintenance for users.

Remote commissioning & training

Guided remote start-up including a training session for users on the operation and maintenance of the equipment.

Maintenance contract

A schedule of regular inspections that encompasses technical assessments, probe calibration, and adherence to the preventative maintenance plan, along with discount rates.

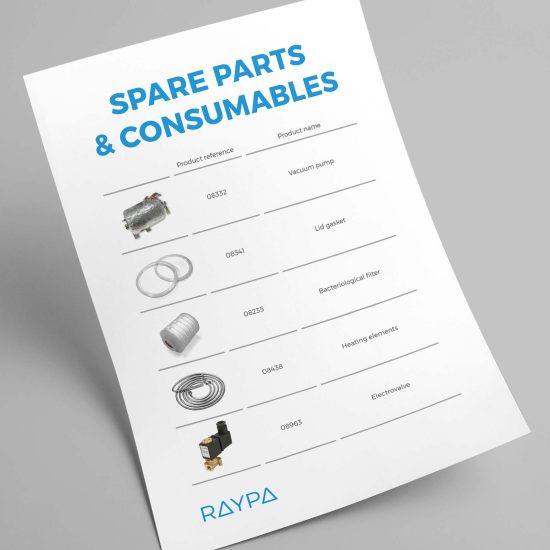

Set of consumables, spare parts and essential components

Set of original spare parts, consumables, and components, chosen specifically to adhere to each model's maintenance plan, intended to maximize equipment longevity and minimize downtime in the event of a malfunction.

Warranty extension

Extended warranty up to a total of 3 years.

You may also be interested in

Vertical medical autoclaves without drying

- AES-MD Series

- Classic Line

Vertical medical autoclaves with prevacuums and drying

- AE-B-MD Series

- Classic Line

Vertical medical autoclaves with super-drying system

- TLV-PD-MD Series

- Top Line

Front-loading Benchtop Medical Autoclaves with Drying

- AHS-DRY-MD Series

- Classic Line

Benchtop medical autoclaves with prevacuums and drying

- AHS-B-MD Series

- Classic Line

Subscribe to our newsletter

"*" indicates required fields