Autoclaves > Top line verticals TLV-FA Series

Vertical autoclaves with fast cooling system

Designed specifically for the pharmaceutical and biotech industries, the TLV-FA Series vertical autoclaves excel in sterilizing liquid loads thanks to their fast cooling system that includes pressure support.

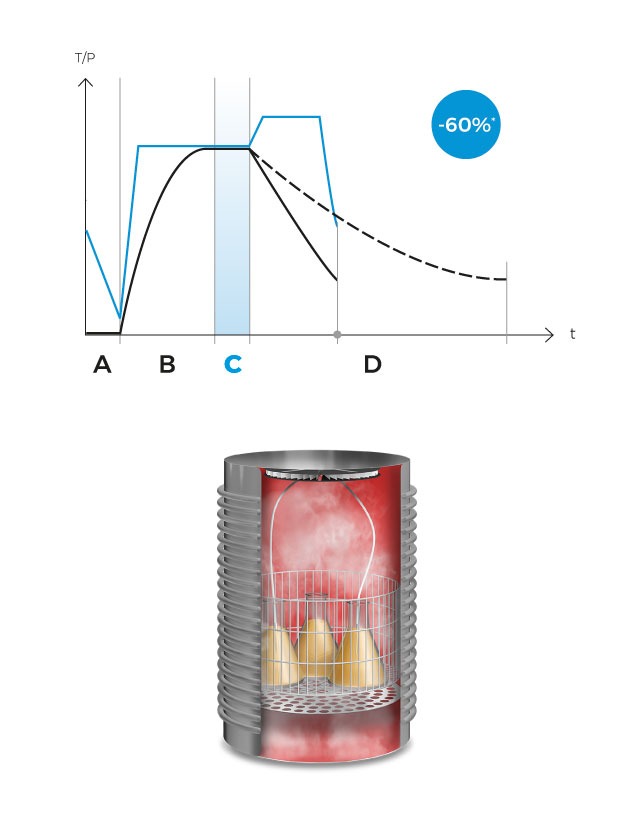

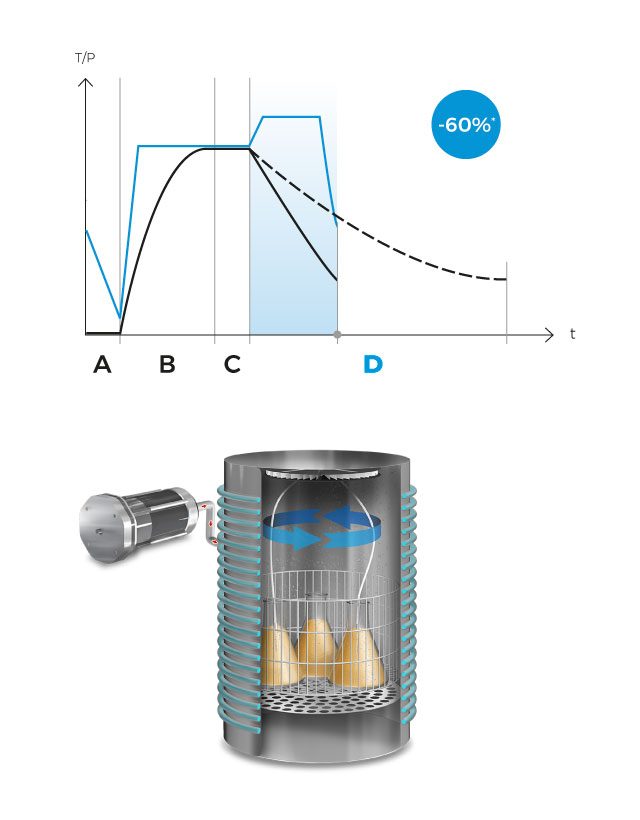

- Up to 60% faster sterilization of liquids

- Fully automatic, equipped with cutting-edge engineering and exceptional quality in every detail

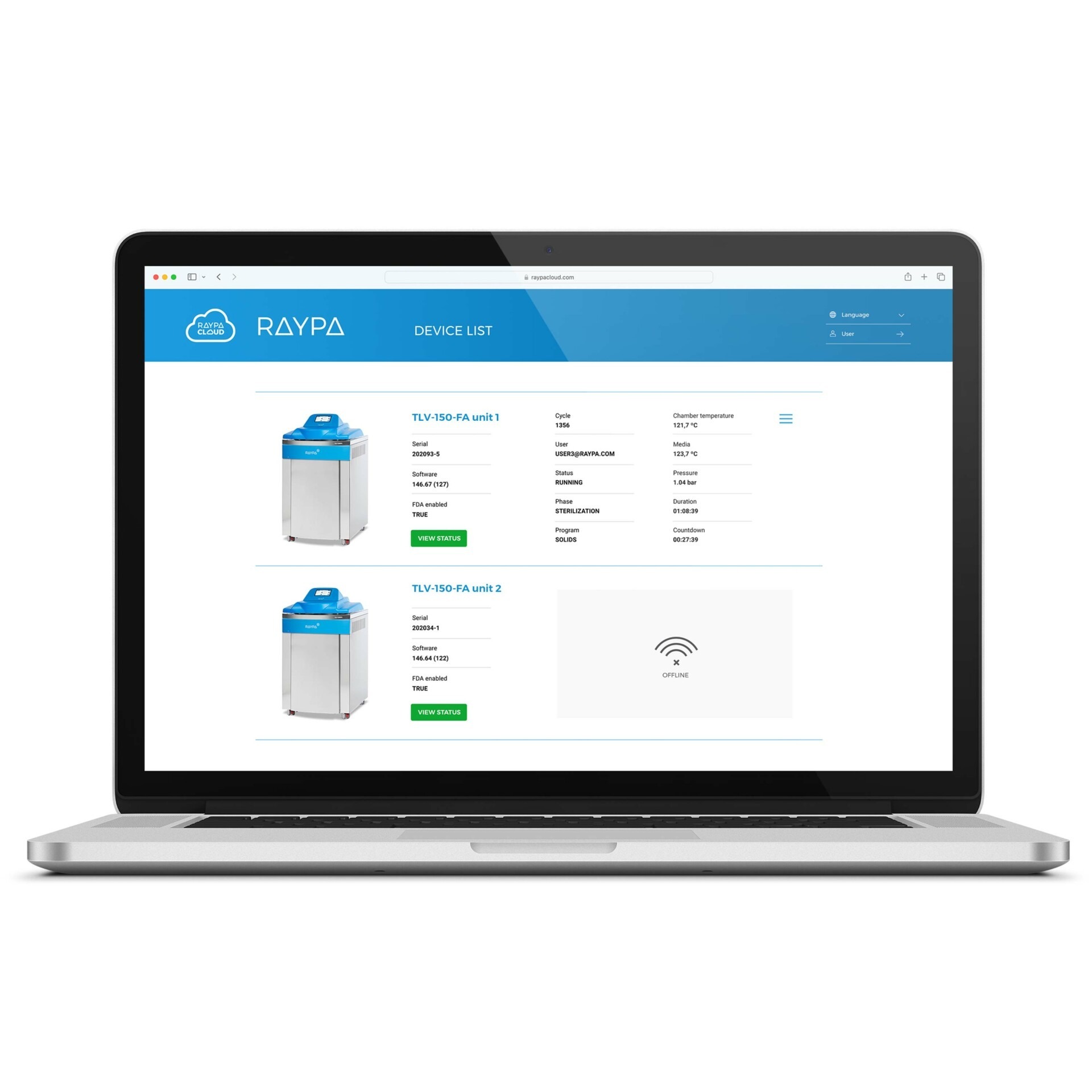

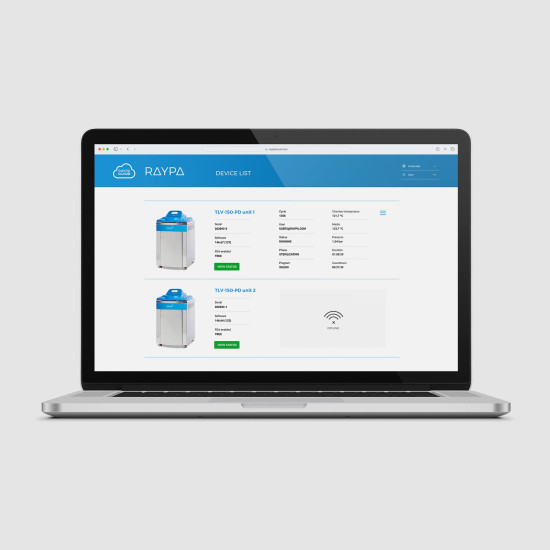

- Advanced cloud-based connectivity that complies with FDA, GMP, and GLP standards

Vertical laboratory autoclaves with fast cooling system

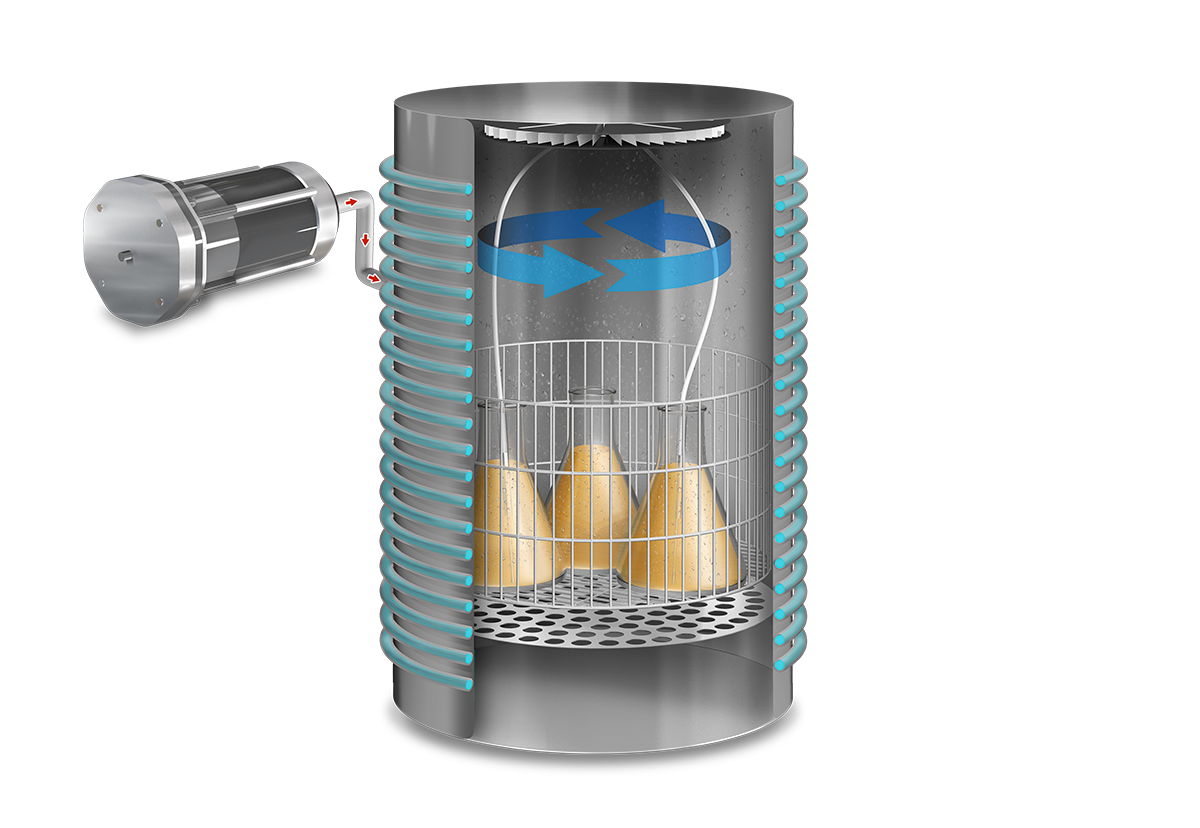

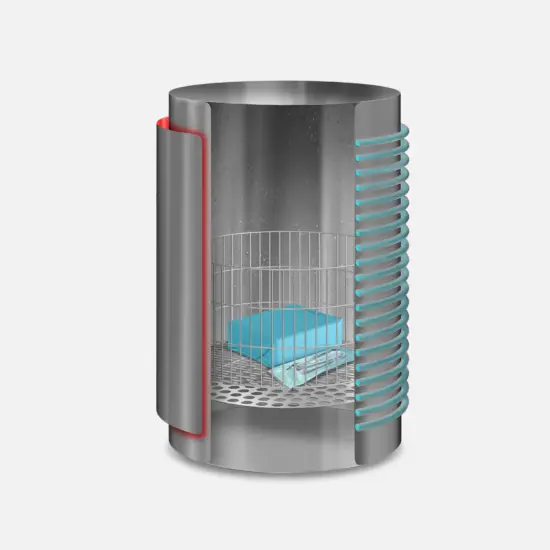

The TLV-FA Series vertical autoclaves are equipped with a fast cooling system including water coil, air compressor, internal fan and flexible probes. They are specially designed to provide advanced liquid sterilization in industrial and research environments in the pharmaceutical, chemical and biotechnology industries sterilizing aqueous solutions, liquid agar, lysogenic broth or pre-filled syringes. They can also process solid loads.

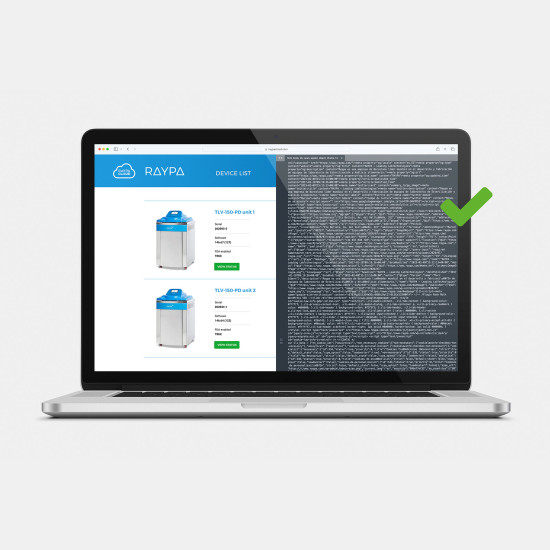

Top line vertical autoclaves enable fully digital operation. All models are equipped with the most advanced connectivity on the market and comply with the latest advances in electronic records and data control to be able to work under FDA, GMP and GLP environments.

State-of-the-art technology for advanced liquid sterilization

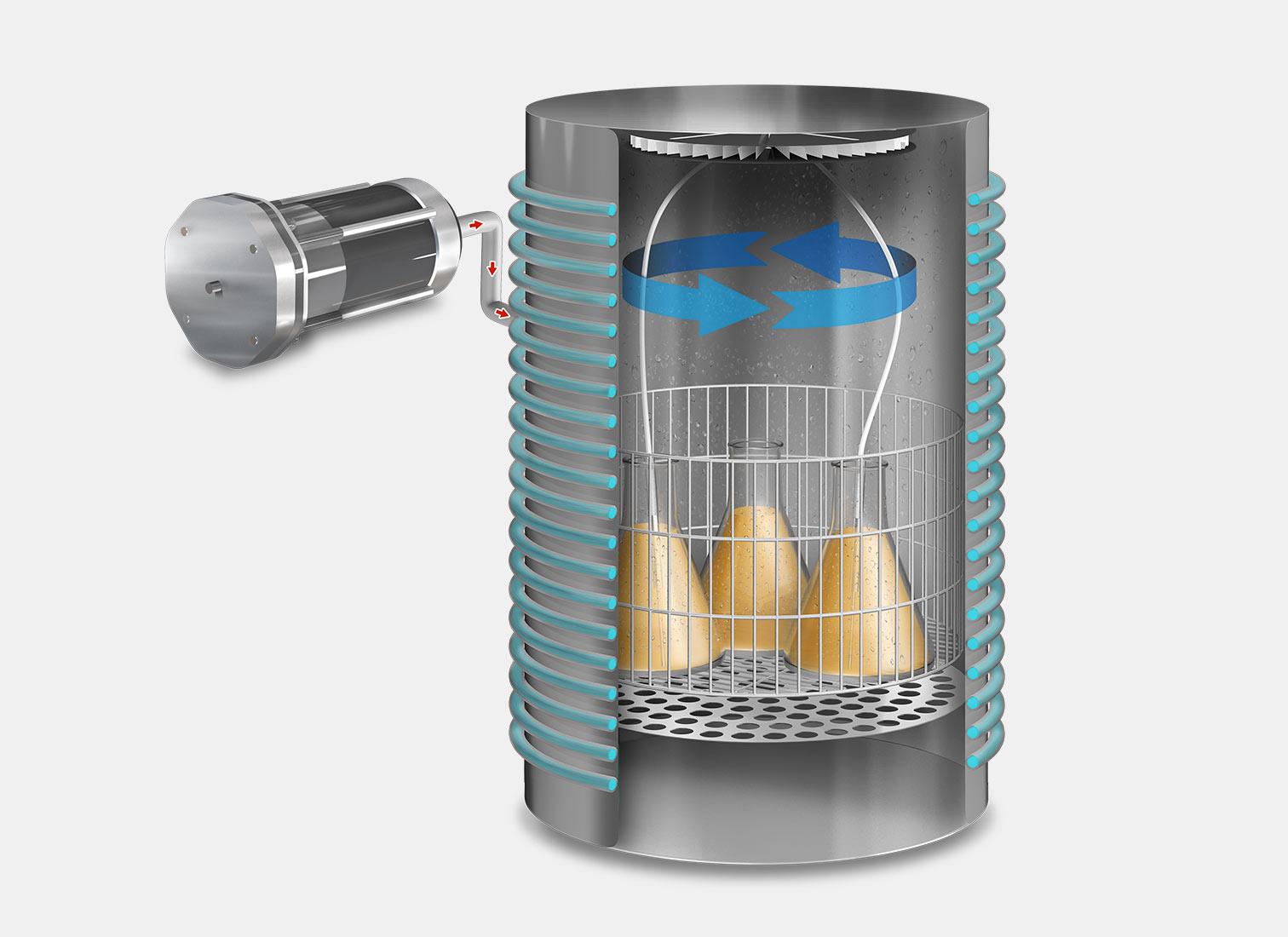

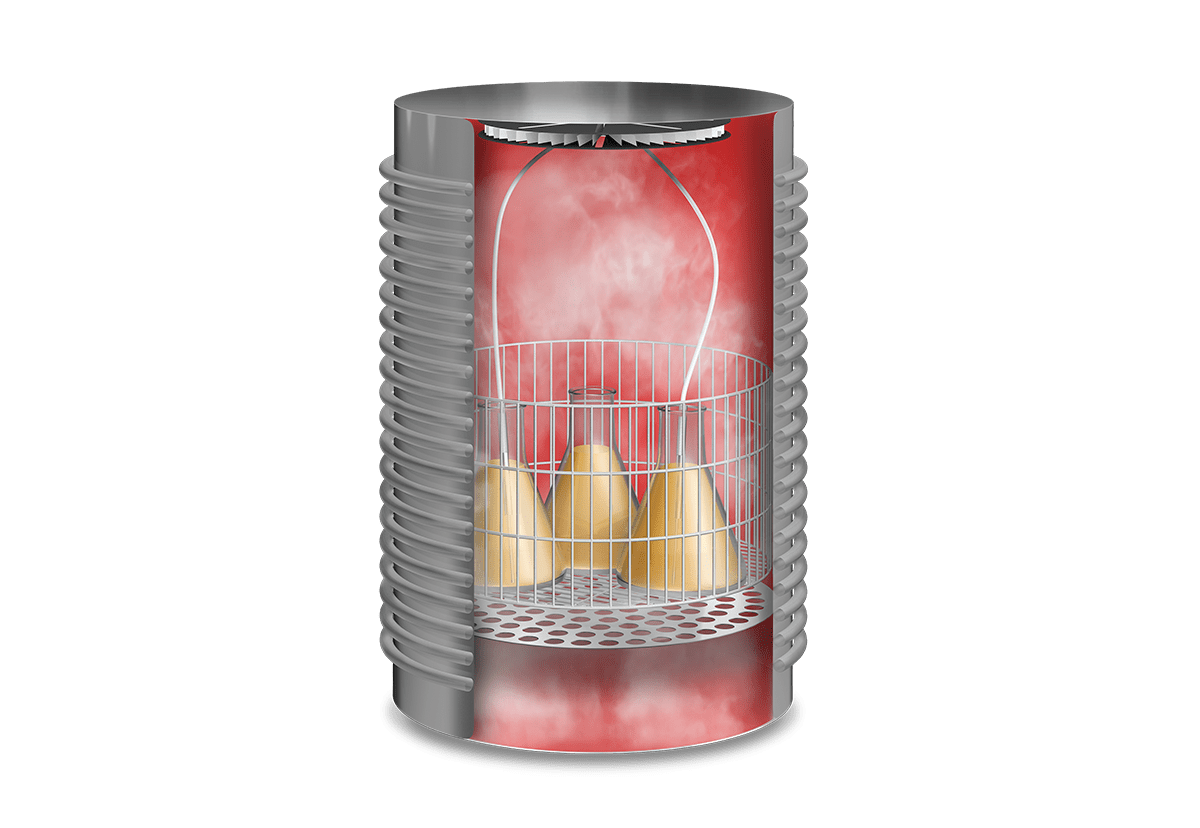

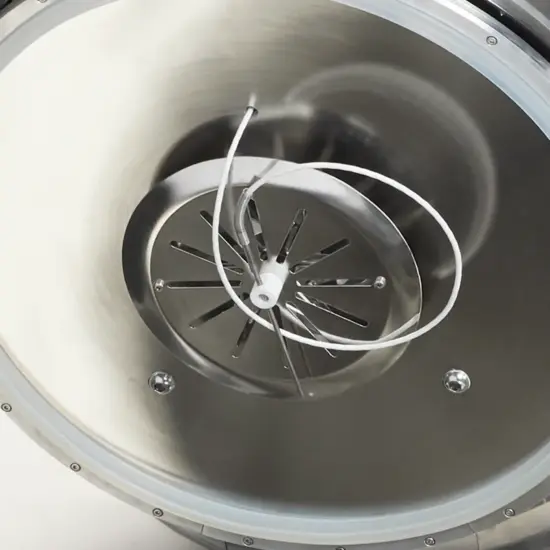

Thanks to its fast cooling system consisting of a radial fan, water coil and air compressor, you will be able to sterilize liquid loads more quickly. Install up to 2 flexible probes and conduct F₀-controlled sterilizations.

Modern design and fully automatic

State-of-the-art technology. Push-button-controlled mechanically assisted door. Instant steam production by the built-in steam generator. Air inlet and outlet fitted with a bacteriological filter. Equipped with a vacuum pump and an air compressor. High-performance fast cooling system composed of water cooling coils, internal radial fan and pressure support. Automatic filling from the water network. Water-cooled direct discharge.

Cloud-based connectivity and advanced technical support

Advanced technical support: Book and request technical assistance directly from the controller, use TeamViewer® for screen sharing, and authorize a remote diagnosis of the equipment's status. Additionally, enjoy centralized management for several autoclaves with tailored reports, handle notifications across multiple devices, and ensure automatic traceability for audits, all protected with SSL encryption. The cloud-based management software is adaptable for integration on a private server through Docker, Active Directory, or LIMS.

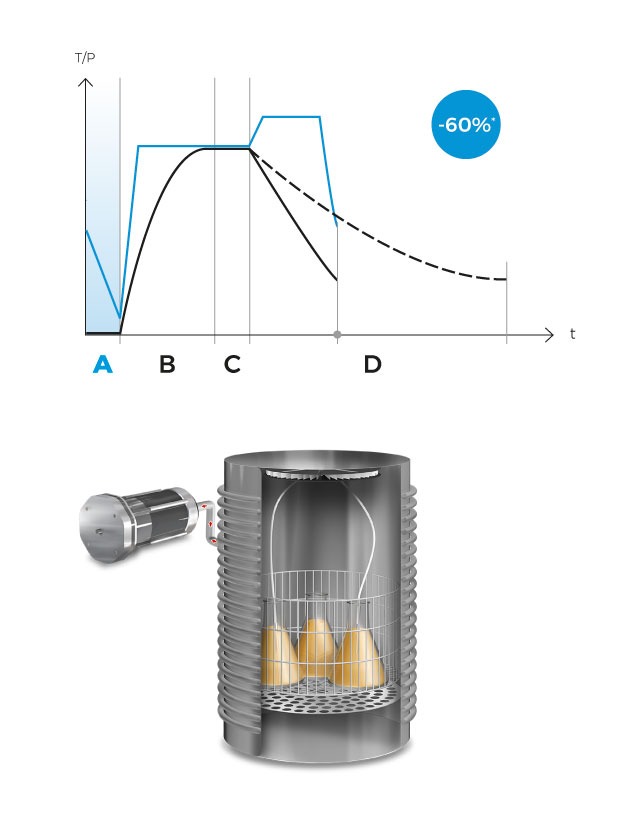

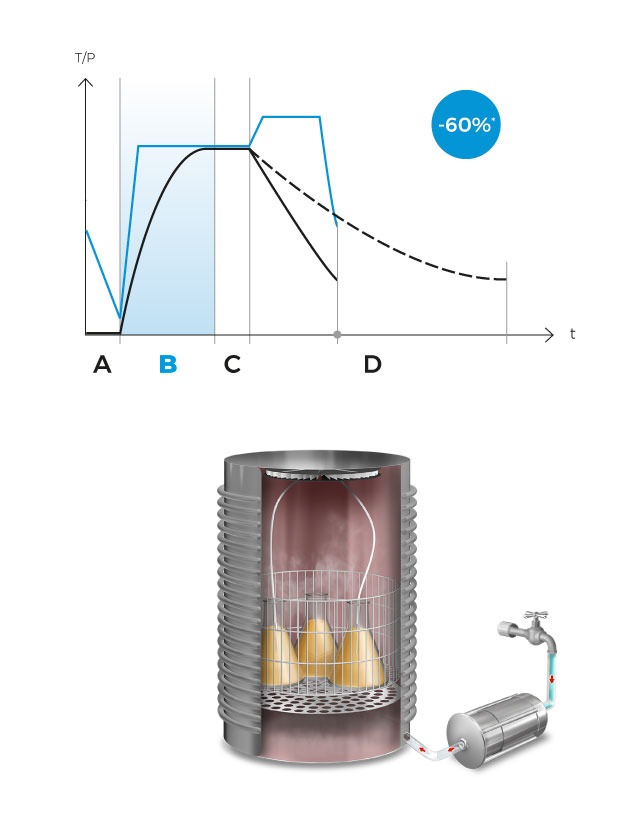

Operation

Temperature

Pressure

Operation

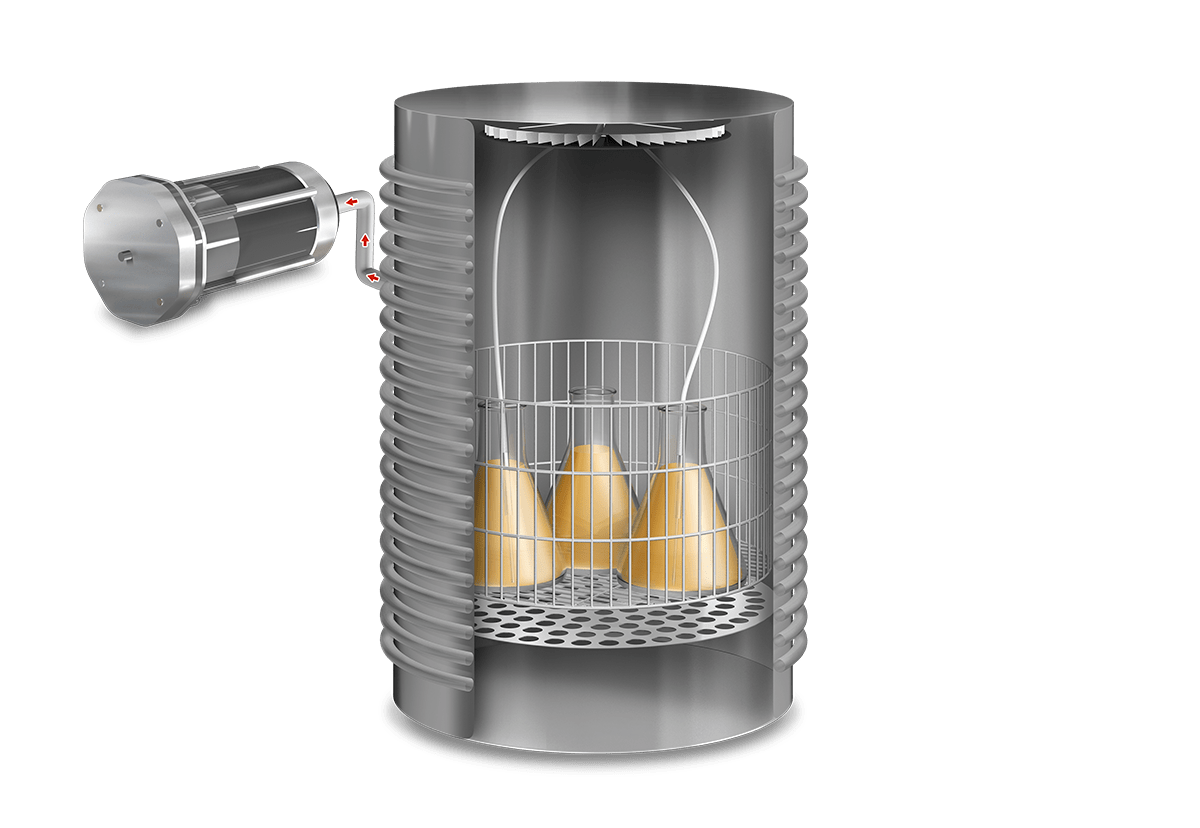

In this phase the cold air in the chamber is mechanically purged to the outside by means of a vacuum pulse, reducing the presence of non-condensable gases and facilitating the penetration of steam throughout the load.

Temperature

Pressure

After completing the first vacuum pulse, the steam generator is activated and will inject saturated steam into the sterilization chamber until the sterilization temperature is reached.

Temperature

Pressure

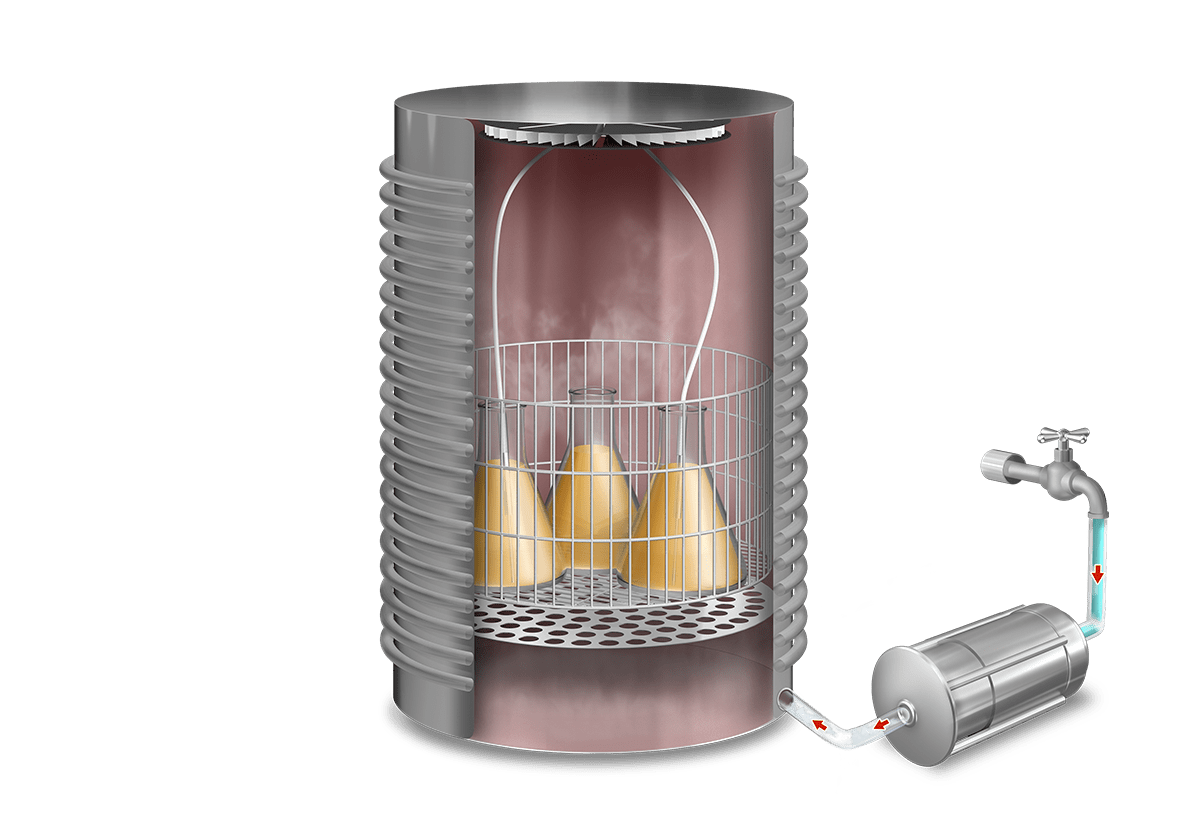

Upon reaching the sterilization temperature in the medium, the sterilization phase begins and the temperature is accurately sustained for the predefined duration.

Temperature

Pressure

Finally, a fast cooling phase begins, featuring pressure support along with the activation of the water cooling coils and internal radial fan to quickly cool the load. Optionally, the agar mode can be configured to maintain a constant temperature.

Temperature

Pressure

Applications

LIQUIDS AND CULTURE MEDIA

The fast cooling system saves a lot of time. Additionally, you can perform F₀-controlled sterilizations and without the need to hurry when removing the load thanks to the agar mode.

PLASTICS AND METAL OBJECTS

Sterilize plastics and metal objects conveniently with faster cycles thanks to the steam generator

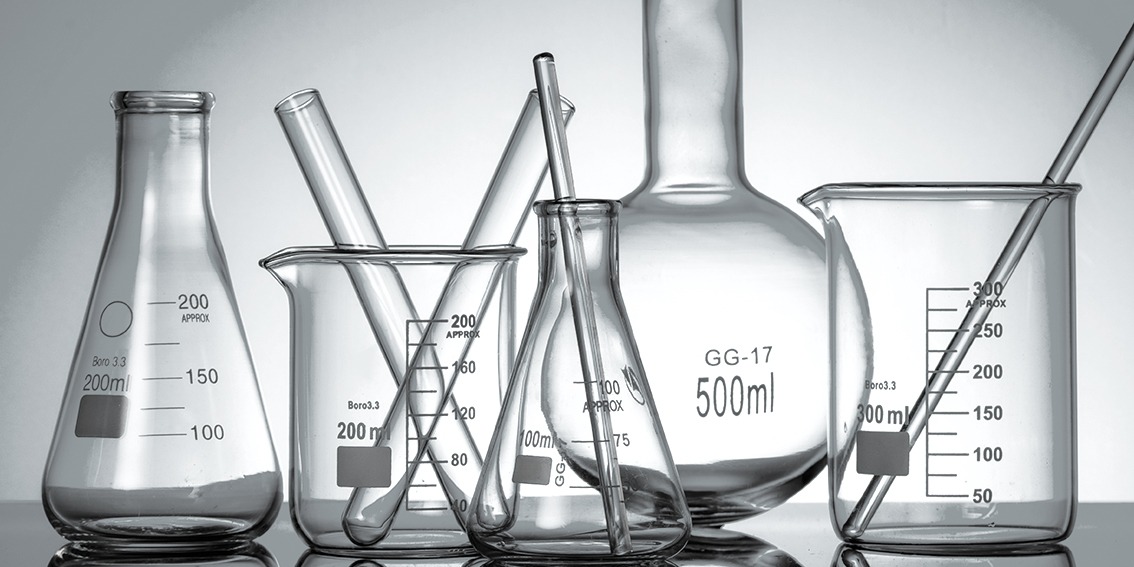

GLASSWARE

Ensure the purity of your glass instruments thanks to the steam generator that produces high-quality steam, which minimizes salt transfer during processing.

LABORATORY WASTE BAGS

Thanks to the initial prevacuum pulse and the steam generator, you can sterilize waste bags without any problems.

BIOHAZARDOUS WASTE

The bacteriological filter at the air inlet and outlet of the chamber allows the processing of biohazardous loads.

PRE-FILLED SYRINGES AND HERMETICALLY SEALED OBJECTS

Effectively sterilize pre-filled syringes and sealed objects using pre vacuum technology and uniform steam, ensuring the integrity of the materials.

Technical data

| References |

|---|

| Total/usable volume of the chamber (L) |

| Usable dimensions of the chamber (Ø x H mm) |

| External dimensions (L x D x H mm) |

| Loading height (mm) |

| Net weight (Kg) |

| Power (W) |

| Voltage* (V) |

| Frequency (Hz) |

| TLV-50FA |

| 58/56 |

| 400 x 450 |

| 610 x 870 x 1060 |

| 815 |

| 140 |

| 3600 |

| 230 |

| 50/60 |

| TLV-75FA |

| 83/81 |

| 400 x 650 |

| 610 x 870 x 1110 |

| 865 |

| 151 |

| 3600 |

| 230 |

| 50/60 |

| TLV-110FA |

| 124/118 |

| 500 x 600 |

| 710 x 980 x 1160 |

| 915 |

| 205 |

| 9000 |

| 400 |

| 50/60 |

| TLV-150FA |

| 169/155 |

| 500 x 850 |

| 710 x 980 x 1310 |

| 1065 |

| 220 |

| 9000 |

| 400 |

| 50/60 |

| *Other voltages and electrical configurations available on request. |

Accessories

RAYPACLOUD

License to access the cloud-based management platform, enabling all remote connectivity and diagnostic functions.

Activation of FDA on the controller

Activates all the necessary functions to comply with FDA and GMP regulations: audit trail, automatic backups, electronic signatures, etc.

Internal radial fan

Internal radial fan that significantly reduces cooling time, especially in autoclaves equipped with cooling water coil.

TLV-DUAL Series adaptation kit

Prepares any Top line autoclave for future conversion to the TLV-DUAL Series, allowing the incorporation of super-drying and/or fast cooling systems when necessary.

Flexible probe

Add a second flexible probe for improved sterilization of liquid loads.

Integrated crane

Mobile crane integrated into the side of the autoclave, designed to assist in the loading and unloading of heavy items.

Independent crane

Crane with integrated battery, mobile and independent, designed to assist in the loading and unloading of heavy items.

Wire baskets

Baskets suitable for the sterilization of all types of clean loads.

Wire basket tray

Tray designed to be used in conjunction with wire baskets to collect liquids.

Unperforated baskets

Baskets suitable for sterilization of dirty loads and those at risk of spillage.

Schimmelbusch Drum

Drum suitable for sterilization of medical instruments and biohazardous loads.

Height adjustable tray support

For sterilization of instruments, small bags and other small objects that must be placed straight up.

Integrated ticket printer

Prints program number, cycle number, temperature, date and hour of the run and error messages.

Desktop ticket printer

Prints program number, cycle number, temperature, date and hour of the run and error messages.

Label printer

Allows printing of individual labels with customizable barcode design according to GLP.

Barcode scanner

Allows to read individual labels of each processed load and identify each batch according to GLP.

Eco-efficient water purifier

Eco-efficient direct-flow water purifier without water storage, capable of filtering 1.3L/min with an LED display.

Purified water tank

25L bottle for storing purified water, which will be used to supply the autoclave. This is to be used in conjunction with our water purifier.

Water softener

Prevents scale deposits inside pipes, the cooling system, and the sterilization chamber.

Bacteriological filter for air outlet

Filter that guarantees the sterility of the air expelled by the autoclave, ensuring a safe environment for the personnel and the treated material.

Transport trolley

Auxiliary trolley to assist in loading and unloading the autoclave.

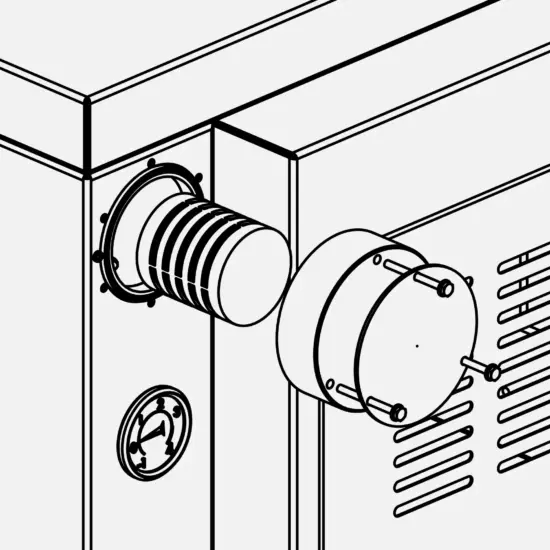

Cable gland

Cable gland allowing access for up to 8 probes for calibration and validation operations.

Temperature recorder

Disk-shaped datalogger for monitoring the temperature inside a load.

Sterilization control tape

Class 1 indicator for steam sterilization.

Integration of the management platform on the client's local server

Integration of the management platform into a local area network via Docker.

Integration within Active Directory

Integration of administrator management, user management and password policies within Active Directory.

IQ-OQ Documentation

Delivery of documentation and IQ/OQ protocol for third party autoclave qualification.

IQ-OQ-PQ qualification

IQ/OQ/PQ autoclave qualification service performed by RAYPA.

FDA validation of the controller

Validation service that the controller complies with FDA 21 CFR Part 11.

FDA validation of the cloud connectivity

Validation service that the cloud-based connectivity or private server complies with FDA 21 CFR Part 11.

Private server

Private cloud server communicating with the autoclave through the local laboratory network with optional FDA and GMP compliance.

On-site commissioning & training

On-site guided start-up that includes the verification of the correct operation and installation of the equipment, complemented by a training session on its operation and maintenance for users.

Remote commissioning & training

Remote start-up including a training session on the use and maintenance of the equipment.

Maintenance contract

A schedule of regular inspections that encompasses technical assessments, probe calibration, and adherence to the preventative maintenance plan, along with discount rates.

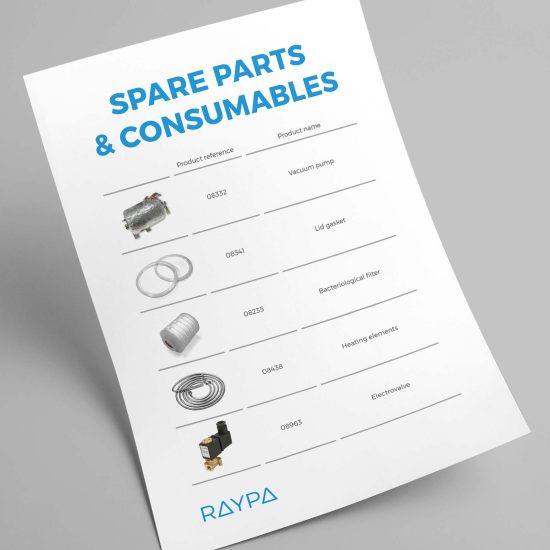

Set of consumables, spare parts and essential components

Set of original spare parts, consumables, and components, chosen specifically to adhere to each model's maintenance plan, intended to maximize equipment longevity and minimize downtime in the event of a malfunction.

Warranty extension

Extended warranty up to a total of 3 years.

You may also be interested in

Vertical autoclaves with super-drying system

- TLV-PD Series

- Top Line

Vertical autoclaves with super-drying and fast cooling system

- TLV-DUAL Series

- Top Line

Subscribe to our newsletter

"*" indicates required fields