Autoclaves > Classic line verticals CFS-V Series

Vertical autoclaves with pressure support for food processing

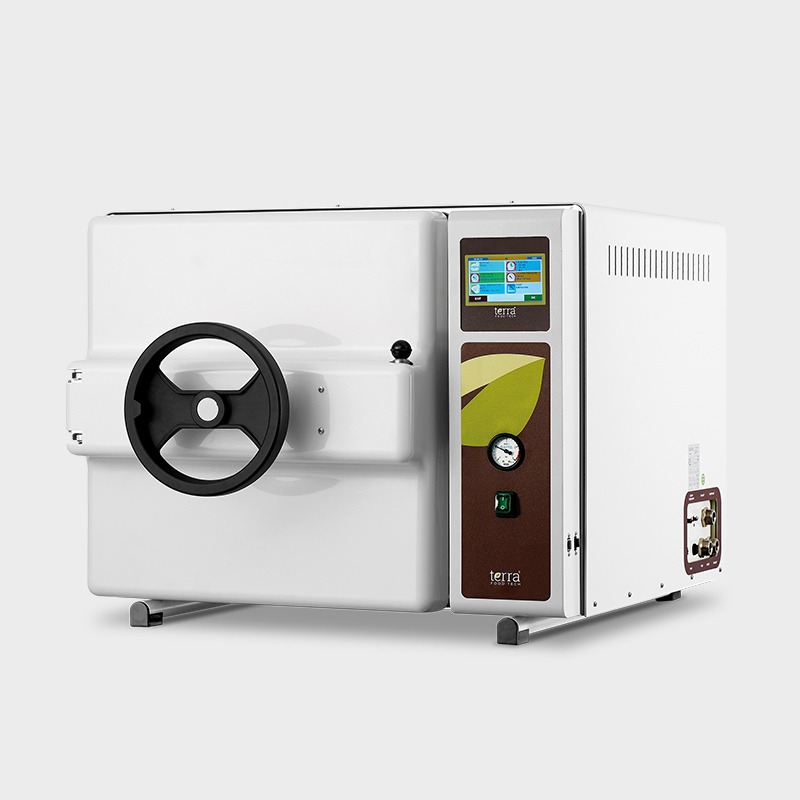

The CFS-V Series vertical autoclaves with back pressure are particularly suitable for processing packaged foods in the food industry.

- Adjustable temperature from 50 to 130ºC and temperature regulation by means of a flexible probe

- Adjustable pressure support up to 2.1 Barg and regulation by F₀ and P₀

- Programs with up to 5 initial segments and 5 final segments, independently adjustable for time, pressure and temperature

Vertical autoclaves with pressure support for the food industry

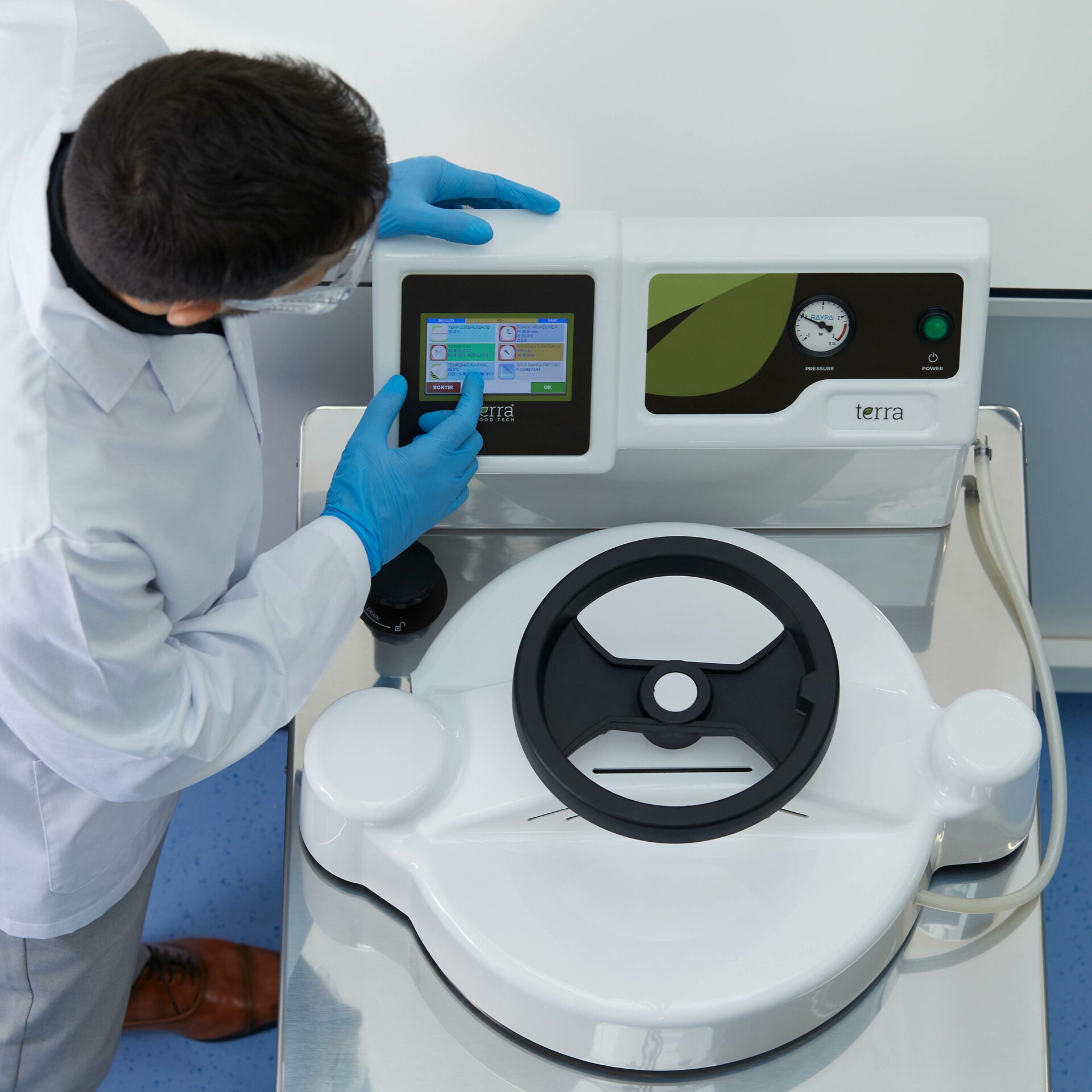

TERRA Food-Tech® autoclaves have been designed to cook, pasteurize or sterilize packaged foods at temperatures between 50 and 130ºC using saturated steam generated by the heating elements mounted inside the sterilization chamber. The temperature is regulated by chamber probe or by the F₀/P₀ values by means of a core probe placed inside a reference sample. This allows a perfect control of the process while preserving the organoleptic properties and minimizing possible changes in the nutritional values of the final product. Choose your model from a wide range of chamber volumes, either in vertical or benchtop configuration. In addition, all units can be supplied with different accessories for specific applications.

The CFS-V Series autoclaves are used in a wide variety of applications and sectors such as commercial production, scientific research in universities, product development in the food industry, research in the packaging industry, and for training purposes at trade schools.

High productivity for small manufacturers of packaged food

It allows the food to be cooked during the same process. Fast cooling to avoid overcooking the packaged product. Time optimization thanks to direct control over the F₀ - P₀ value, guaranteeing the correct pasteurization or sterilization. It respects the organoleptic and nutritional characteristics of the product.

Easy to use, with color touchscreen and memory for up to 50 programs

Adjustable temperature between 50 and 130ºC. Programs with up to 5 initial segments and 5 final segments, independently adjustable by time, pressure and temperature.

Outstanding safety and traceability measures

Our autoclaves have been designed and built to ensure user safety. All sterilization parameters are continuously monitored and recorded to ensure correct operation of the equipment.

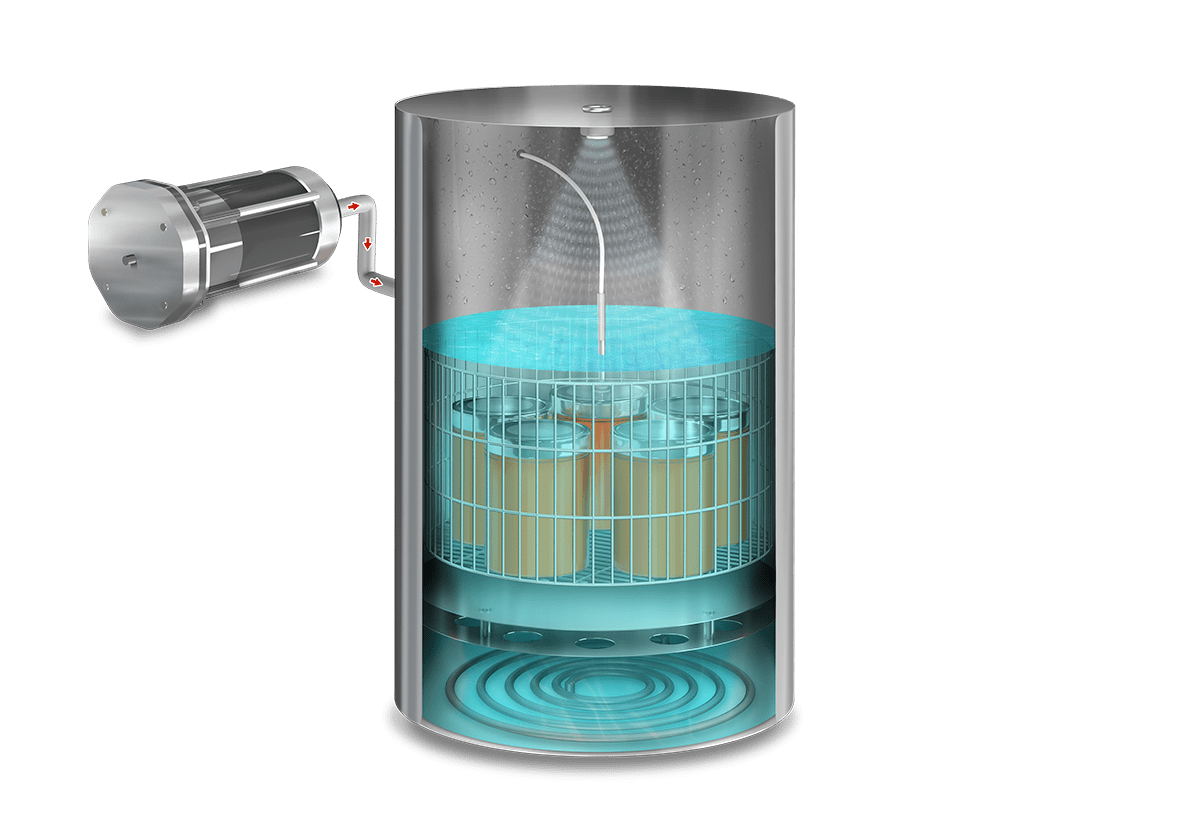

Operation

Temperature

Pressure

Operation

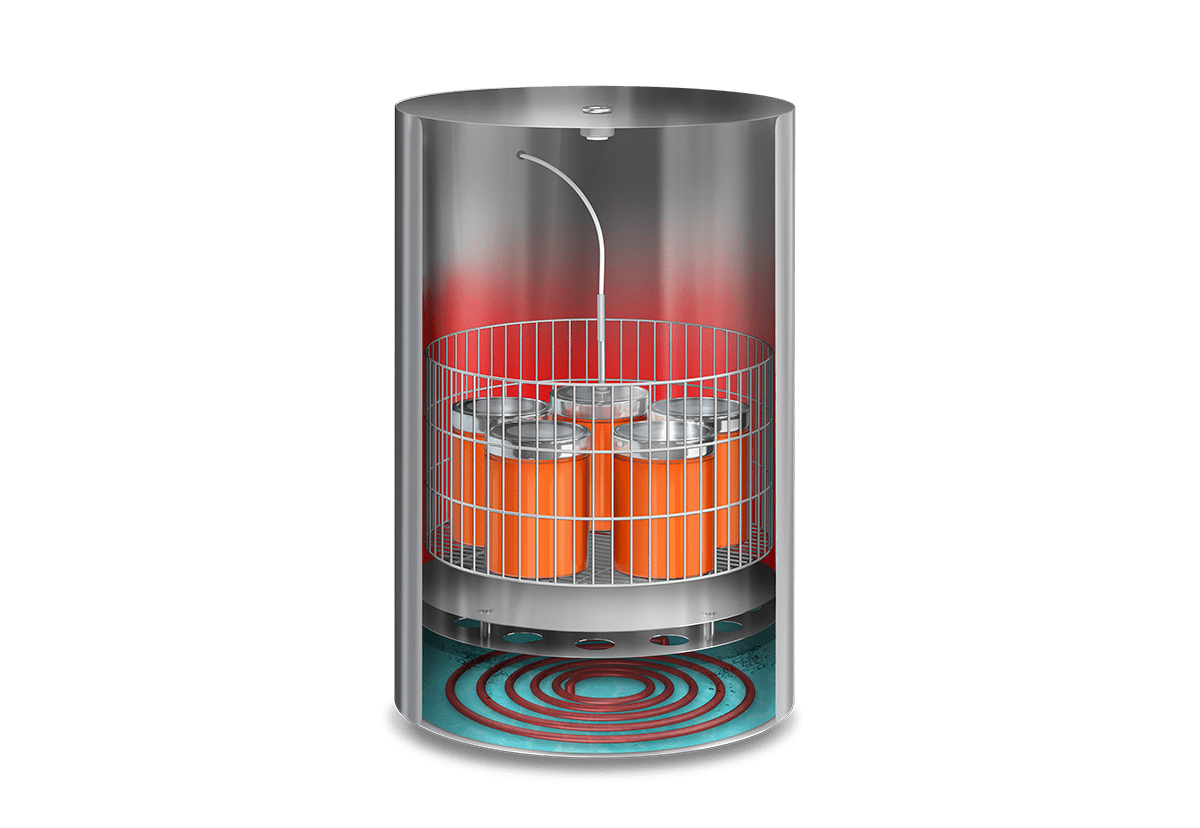

In this initial step, the heating elements mounted at the bottom of the sterilization chamber heat up dramatically, transferring energy to the water to produce steam.

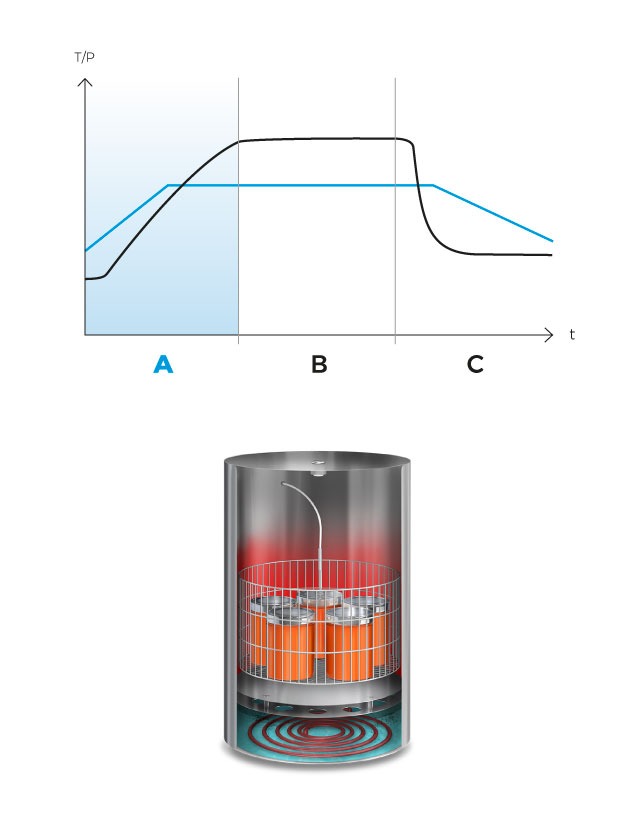

Temperature

Pressure

At 100ºC sterilization begins and the autoclave starts to calculate the F₀ reached in real time. Upon reaching the target processing temperature, the temperature is maintained for the duration of this phase until the reference sample reaches the target F₀. In some acidic products, sterilization occurs at temperatures below 100ºC. This crucial step is controlled by two PT-100 Class A temperature probes located on the wall of the sterilization chamber and inside the reference sample.

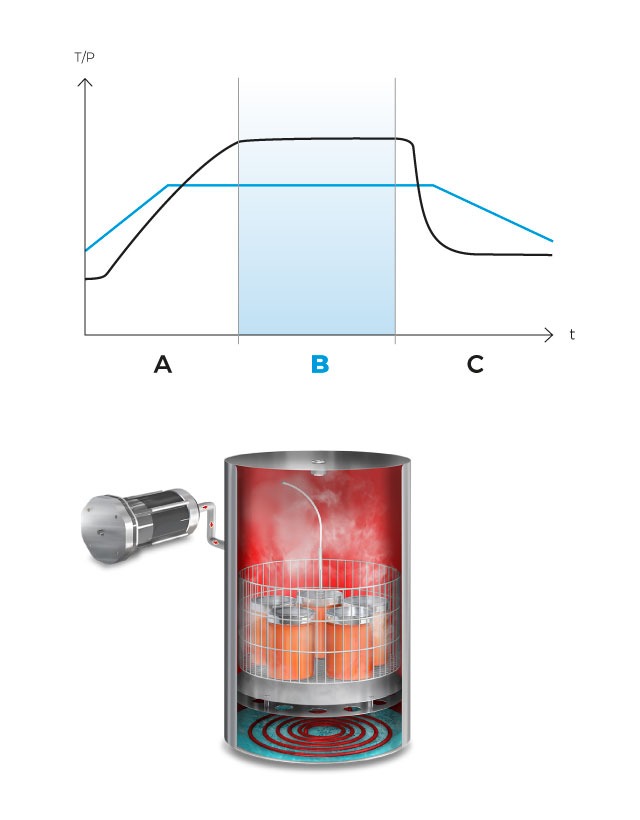

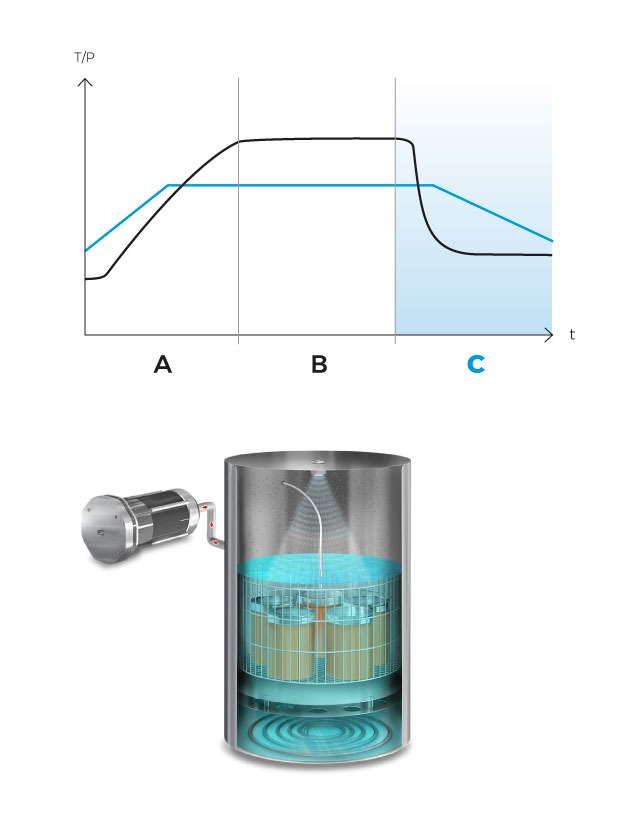

Temperature

Pressure

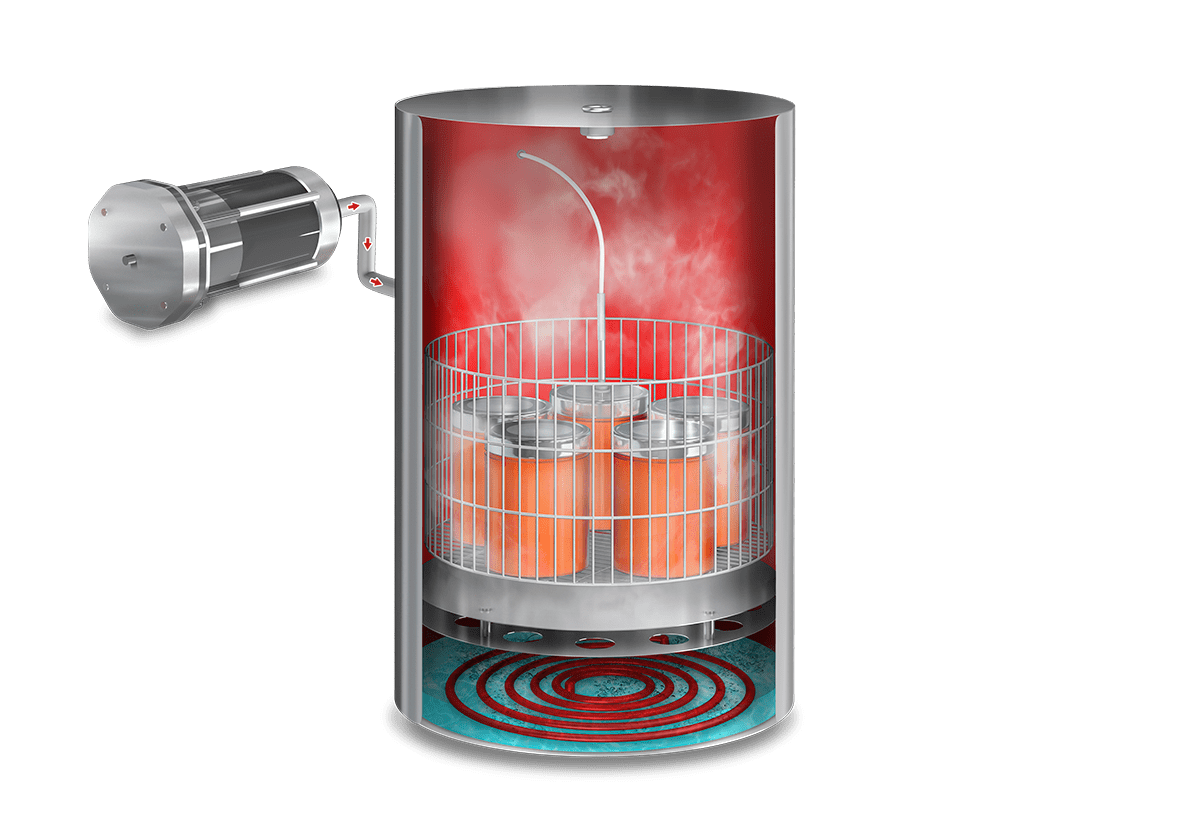

When the target F₀ value is reached, the fast cooling phase begins, with water being rapidly injected into the chamber while the pressure support is activated. Pressure control is essential to avoid damage or breakage of the containers due to the thermal shock caused by the injection of cold water into the chamber. The number and duration of water chamber fillings can be adjusted. The temperature at which the door can be opened can also be adjusted.

Temperature

Pressure

Applications

FOOD INDUSTRY

You will be able to realize versatile and more flexible production lines. Also trials and pilot batches without the need to alter the manufacturing rhythm or travel to the plant to use the production autoclaves.

PACKAGING INDUSTRY

Researchers and quality technicians can safely, and easily perform stress tests and longevity studies with new packaging and materials. Additionally, it facilitates the implementation of quality controls in production lines.

TRAINING IN PROFESSIONAL SCHOOLS

Vocational schools, cooking schools and universities that want to train their students. Our autoclaves can simulate commercial thermal processing, have full control of multiple parameters and make subsequent analysis of the results easy.

RESTORATION

Restaurants, chefs, catering companies, central kitchens, hotel chains and cooking schools that want to prepare gourmet preserves and ready meals in a convenient, safe and simple way.

ENTREPRENEURS

Micro-entrepreneurs, agro-tourism, farmers, cooperatives, small bakeries and associations wishing to prepare and market packaged foods such as gourmet, artisanal or organic preserves.

Technical data

| References |

|---|

| Total/usable volume of the chamber (L) |

| External dimensions (L x D x H mm) |

| Net weight (Kg) |

| Power (W) |

| Voltage* (V) |

| Frequency (Hz) |

| CFS-28V |

| 33 / 30 |

| 505 x 580 x 1110 |

| 90 |

| 3200 |

| 230 (1P+N) |

| 50/60 |

| CFS-50V |

| 55 / 48 |

| 505 x 580 x 1290 |

| 110 |

| 3200 |

| 230 (1P+N) |

| 50/60 |

| CFS-75V |

| 79 / 73 |

| 610 x 700 x 1185 |

| 140 |

| 6000 |

| 400 (3P+N) |

| 50/60 |

| CFS-110V |

| 115 / 104 |

| 610 x 700 x 1435 |

| 180 |

| 6000 |

| 400 (3P+N) |

| 50/60 |

| CFS-150V |

| 175 / 150 |

| 750 x 820 x 1400 |

| 265 |

| 9000 |

| 400 (3P+N) |

| 50/60 |

| *Other voltages and electrical configurations available on request. |

Accessories

Basket lifting crane

Reinforced integrated basket extraction crane.

Integrated thermal printer

Thermal printer capable of automatically printing tickets with details.

Autoclave software for packaged foods

SWTERRA software facilitates viewing, recording, analysis and printing of data for each cycle, with real-time monitoring.

Water softening system

Water softener with ion exchange resins and intelligent programming, designed to prevent scale deposits in autoclaves.

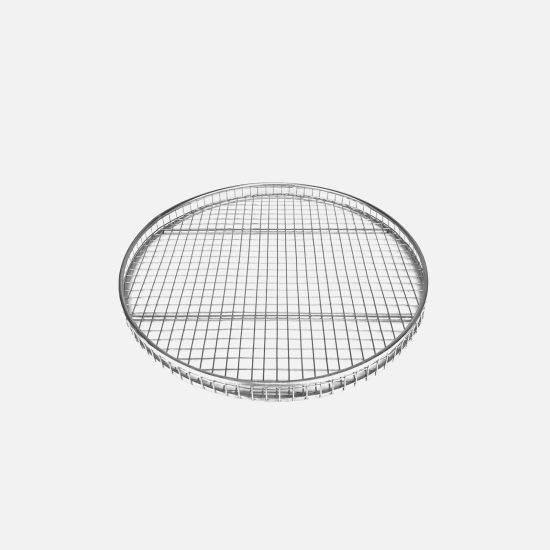

Wire basket

Baskets suitable for the sterilization of all types of clean loads.

Reinforced wire basket

Reinforced stainless steel wire basket for heavy loads.

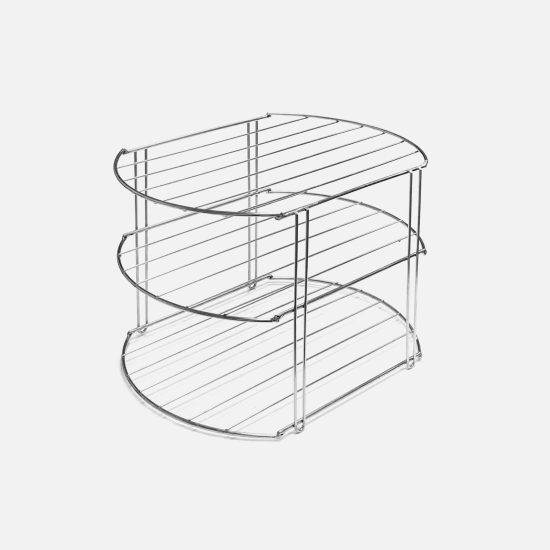

Customized frame

Customized stainless steel frames for flexible packaging.

Additional flexible probe

Additional flexible probe that provides secondary readings for comparison with the main probe.

Temperature data logger

Temperature data logger ideal for monitoring processes in containers where a core probe cannot be used, such as doypacks or plastic trays.

Datalogger connection base

Datalogger connection base with USB cable.

Basket lifting crane

Integrated basket extraction crane.

Independent crane

Crane with integrated battery, mobile and independent, designed to assist in the loading and unloading of heavy items.

Silicone separator

Silicone separator to protect containers from physical defects.

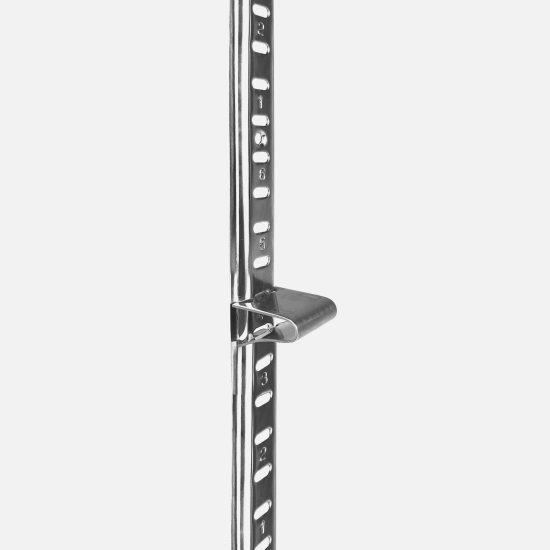

Height adjustable tray support

For sterilization of instruments, small bags and other small objects that must be placed straight up.

Additional tray

Additional tray for SRA.

Set of clips for SRA

Set of clips for SRA - includes 30 units.

External temperature probe adapter

Adapter for continuous validation processes.

Cable gland

Cable gland allowing access for up to 8 probes for calibration and validation operations.

Drilling kit

Perforator kit for containers with metal lids.

Drilling kit

Sleeve with gasket for all types of containers.

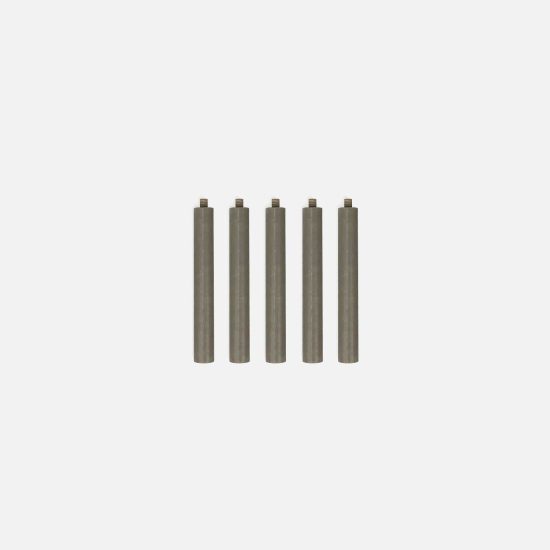

Replacement of 5 separators

Replacement of 5 spacers for 20, 30, 40, 50, 60, 60, 70, 80 or 90 mm probe.

Consulting services

Longer advisory service for experienced customers.

IQ-OQ Documentation

Delivery of documentation and IQ/OQ protocol for third party autoclave qualification.

IQ-OQ-PQ Qualification

IQ/OQ/PQ autoclave qualification service performed by RAYPA.

On-site commissioning & training

On-site guided start-up that includes the verification of the correct operation and installation of the equipment, complemented by a training session on its operation and maintenance for users.

Remote commissioning & training

Guided remote start-up including a training session for users on the operation and maintenance of the equipment.

Maintenance contract

A schedule of regular inspections that encompasses technical assessments, probe calibration, and adherence to the preventative maintenance plan, along with discount rates.

Set of consumables, spare parts and essential components

Set of original spare parts, consumables, and components, chosen specifically to adhere to each model's maintenance plan, intended to maximize equipment longevity and minimize downtime in the event of a malfunction.

Warranty extension

Extended warranty up to a total of 3 years.

You may also be interested in

Benchtop autoclaves with pressure support for research

- CFS-H Series

- Classic Line

Subscribe to our newsletter

"*" indicates required fields