Autoclaves > Classic line benchtop AHS-B-MD Series

Benchtop medical autoclaves with prevacuums and drying

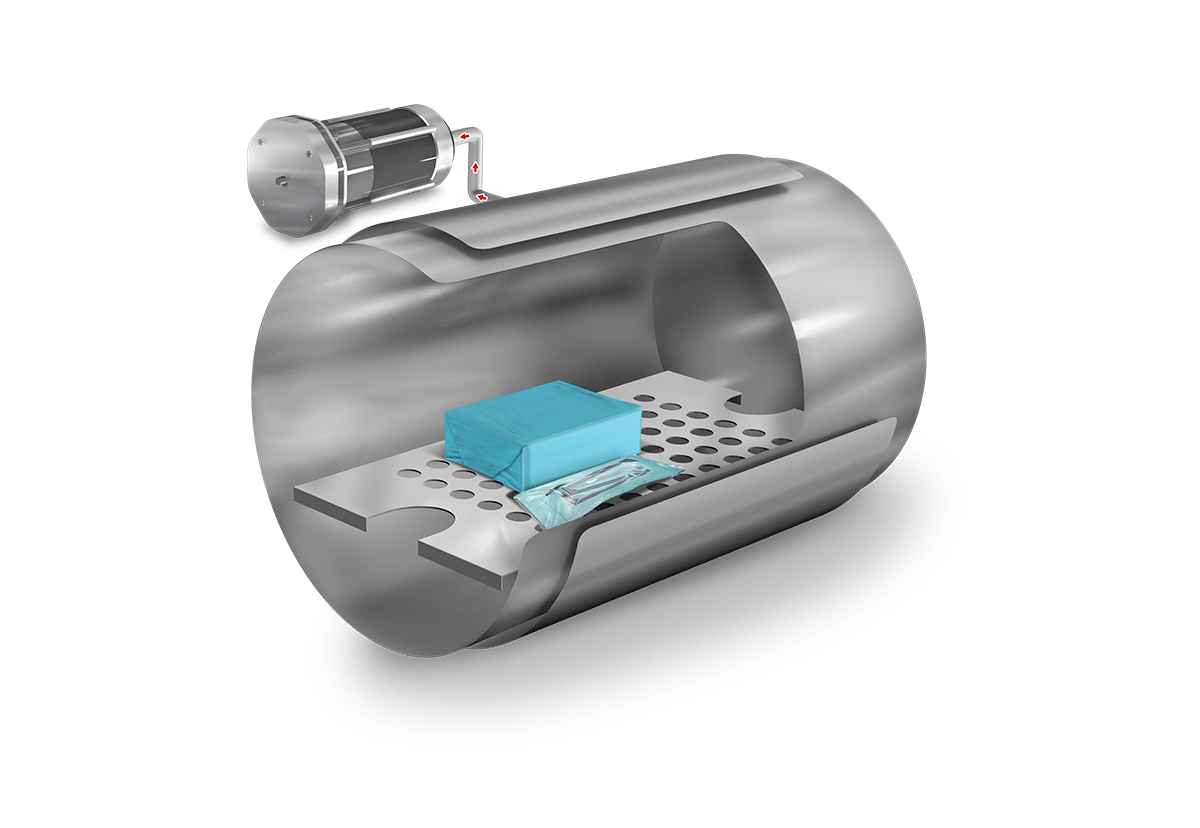

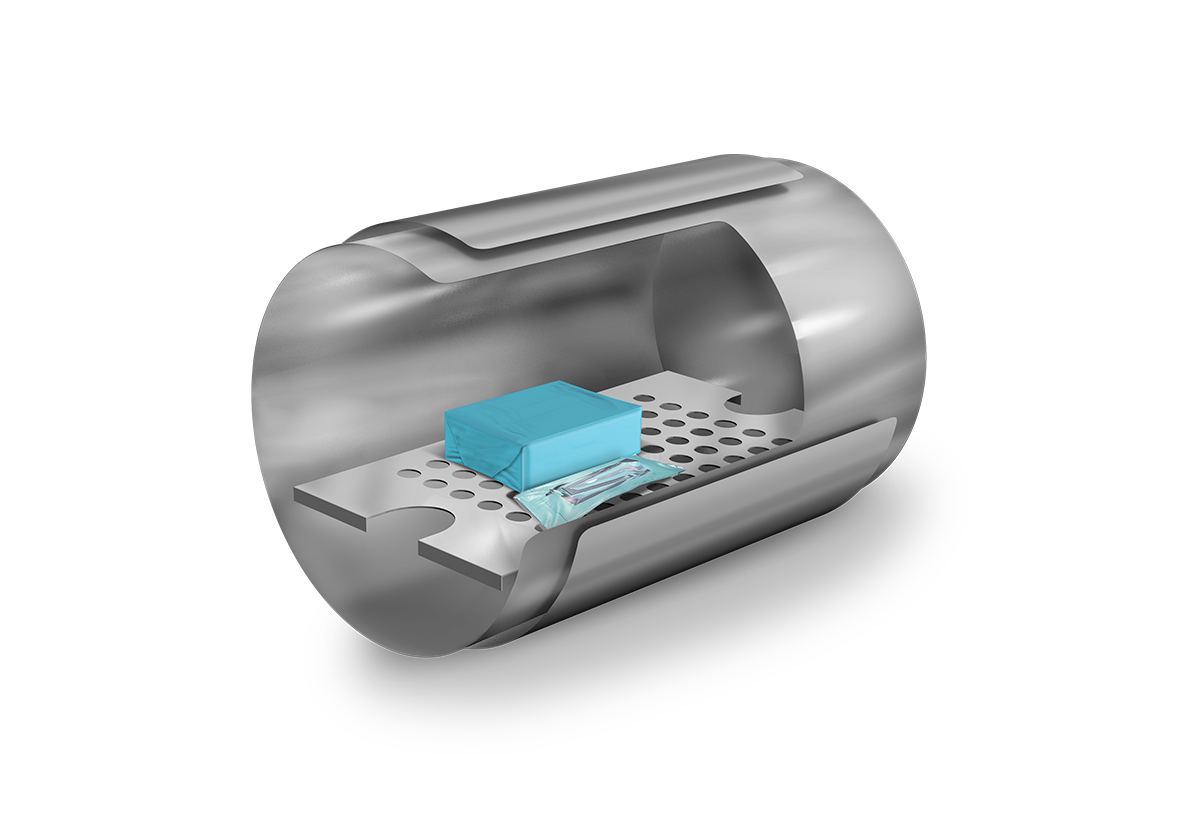

The AHS-B-MD Series benchtop medical autoclaves with prevacuums and drying are particularly suitable for sterilizing solid loads and objects with complex geometries.

- Advanced features and total versatility for multiple applications

- Solid loads are completely dry upon cycle completion

- Compact design and 5'' touchscreen with 50 programs

Benchtop medical autoclaves with prevacuums and drying

The AHS-B-MD Series benchtop medical autoclaves have advanced features to meet all the sterilization needs of medical facilities to increase productivity and process all types of loads.

They are specially optimized for processing loads that require a higher steam penetration capacity to be properly sterilized such as porous solids, packaged loads, objects with cavities, items with complex geometries as well as liquids.

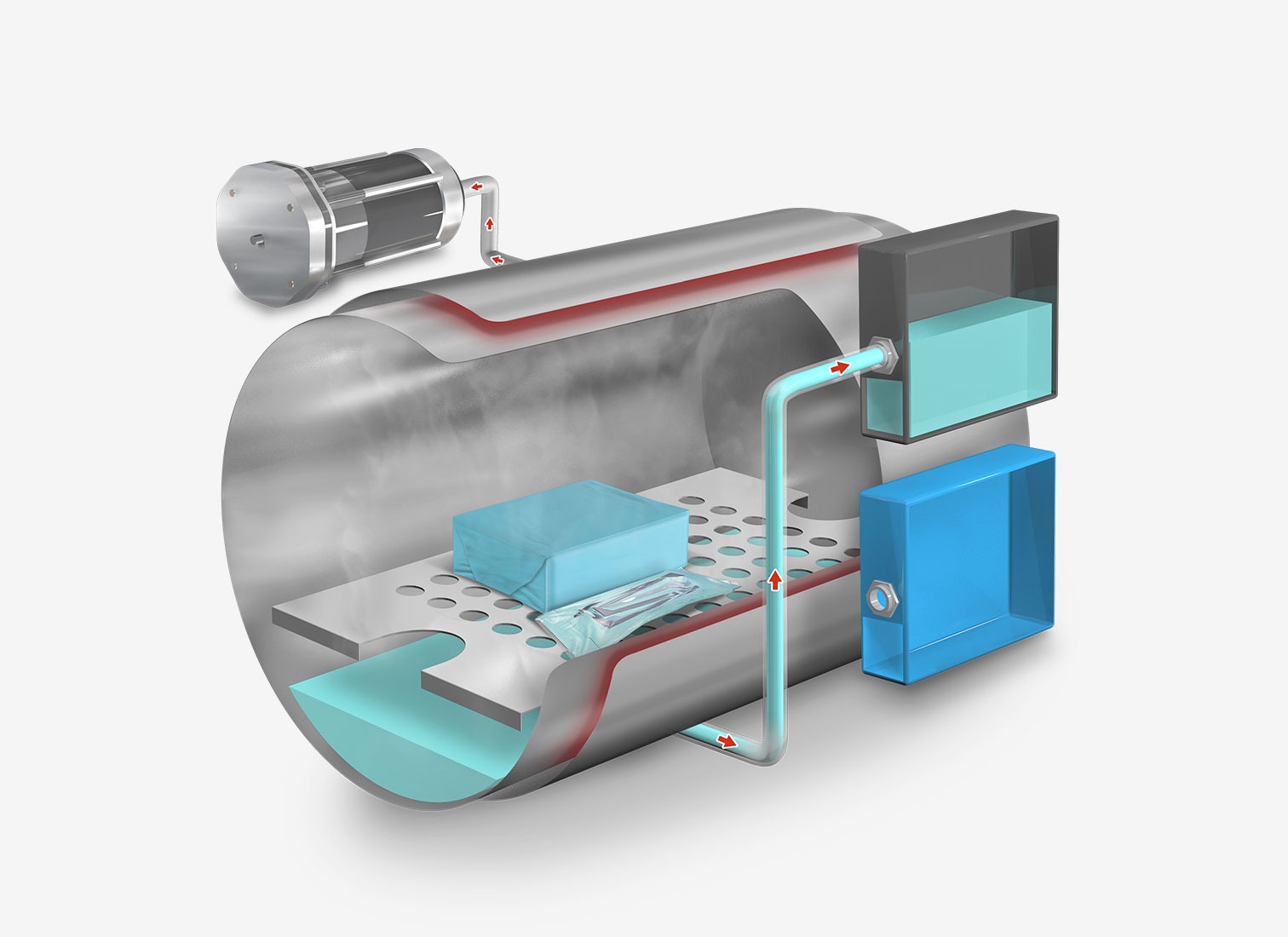

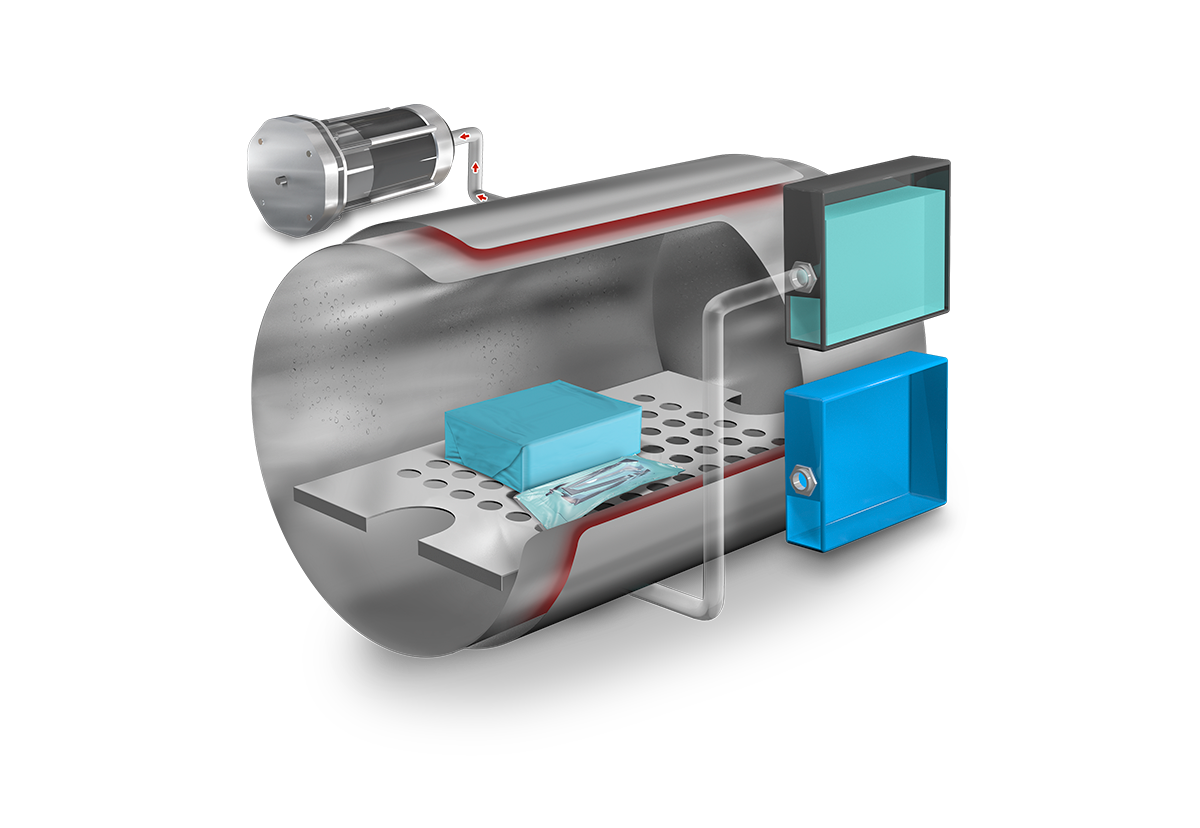

Thanks to their outstanding versatility in sterilizing all types of loads, the integrated independent steam generator, touchscreen display, separate clean water tank, initial prevacuum pulses, final vacuum drying, and direct water discharge, these autoclaves excel in performing everything from the simplest to the most demanding applications.

Fast sterilizations with deep steam penetration

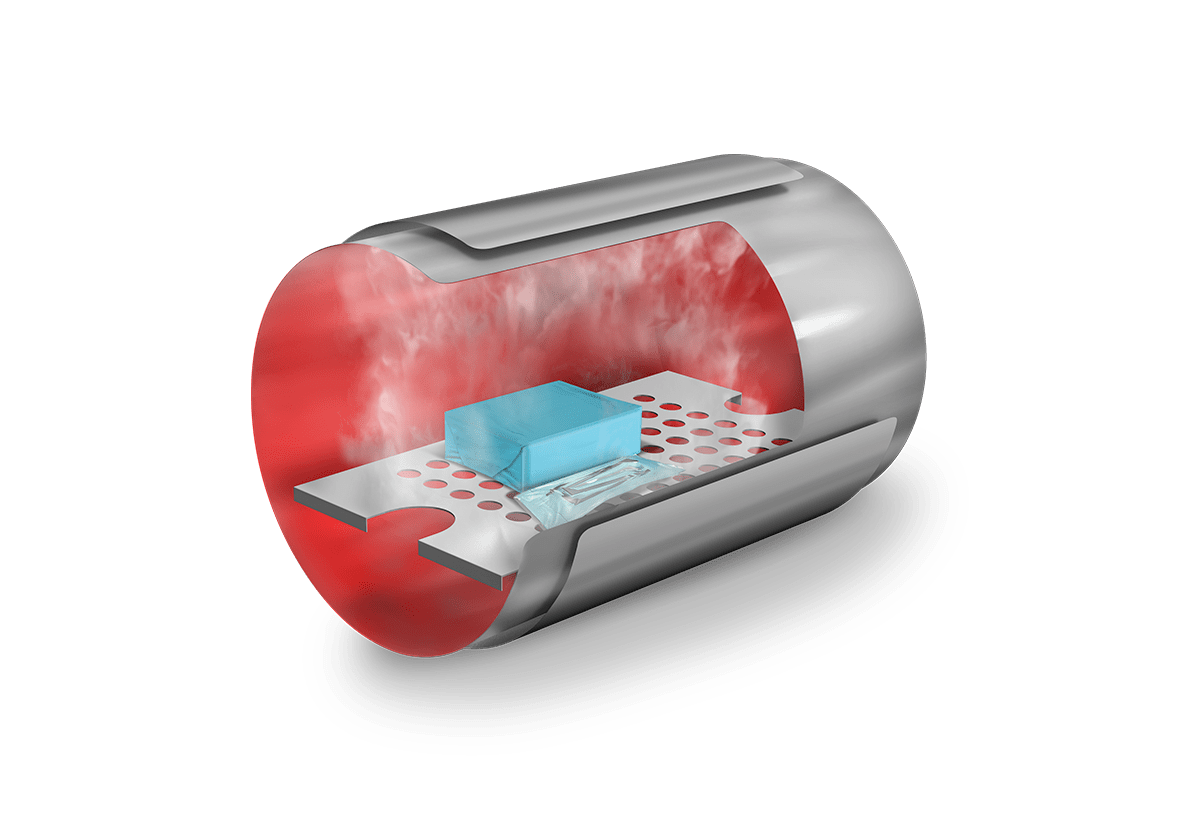

Achieve fast cycle times with instant steam production from the built-in steam generator. The pre-vacuum phase, featuring multiple vacuum pulses, thoroughly removes air pockets, ensuring effective sterilization of all types of loads.

Thoroughly dries the load with the final drying function

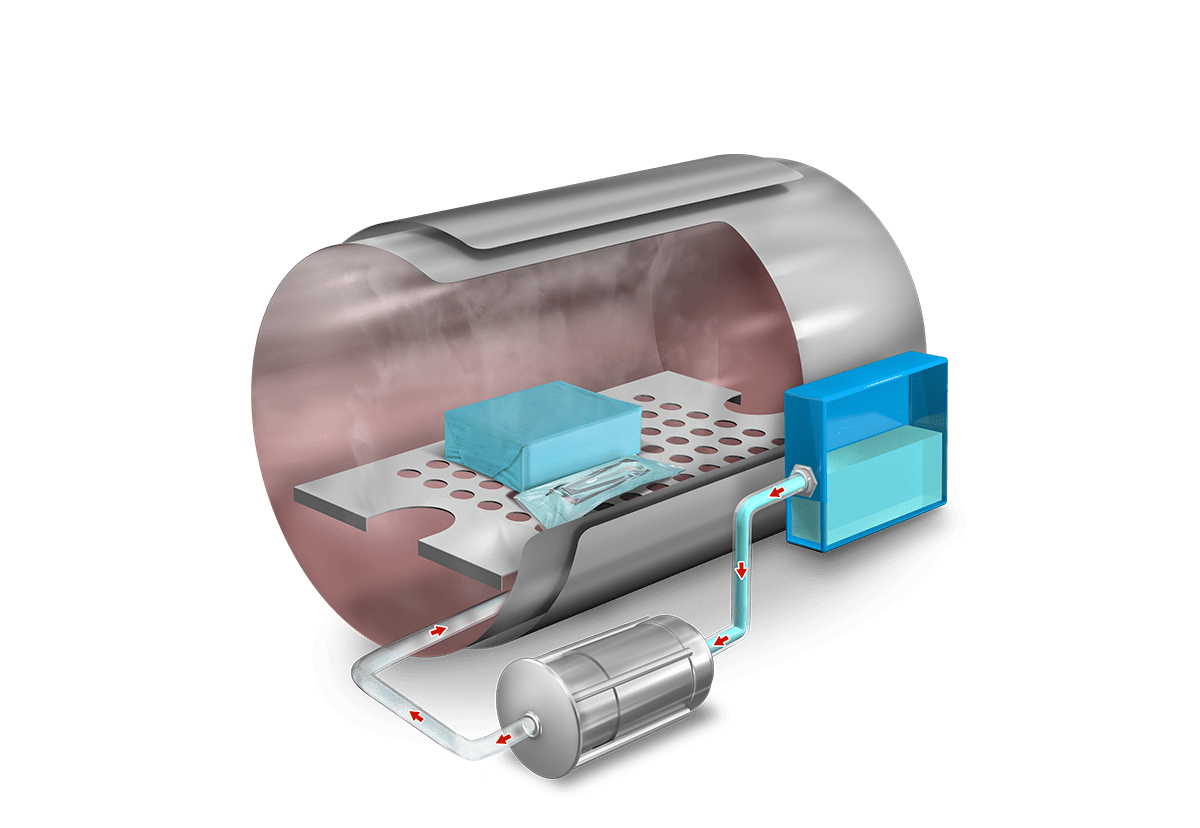

Thanks to its final drying function using a heating jacket and vacuum pump, the load will be completely dry at the end of the cycle, ensuring safe processing of porous solids and packaged objects. There is no need to dry the load in an external oven.

Advanced features and fully automatic

Touchscreen display with up to 50 programs, mechanical purge and integrated steam generator. Includes bacteriological filter and water tanks. Filling with purified water can be automated. Includes bacteriological filter and water tanks. Filling with purified water can be automated.

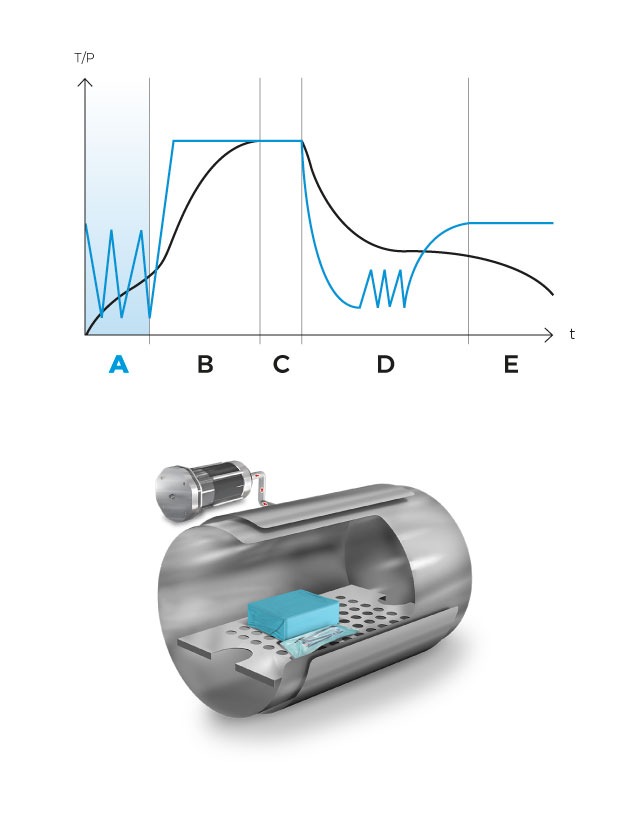

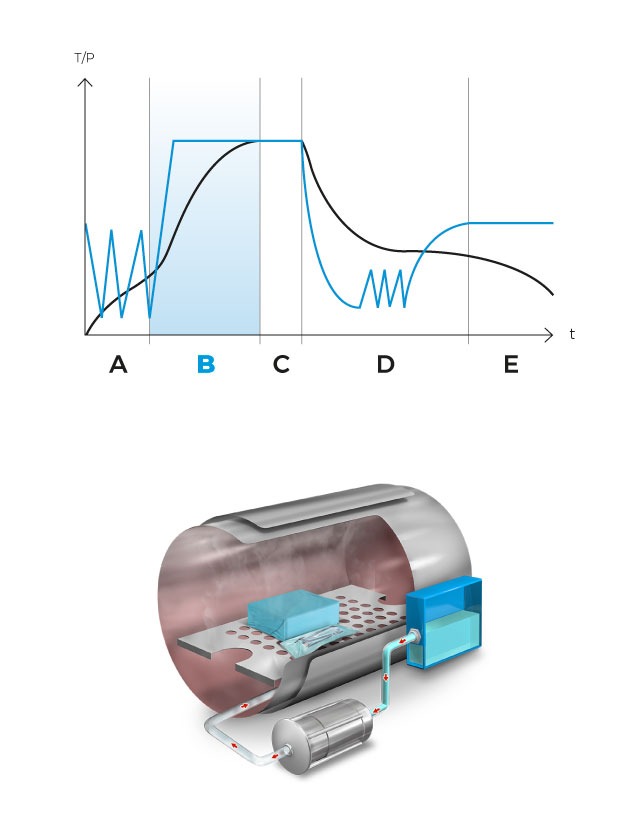

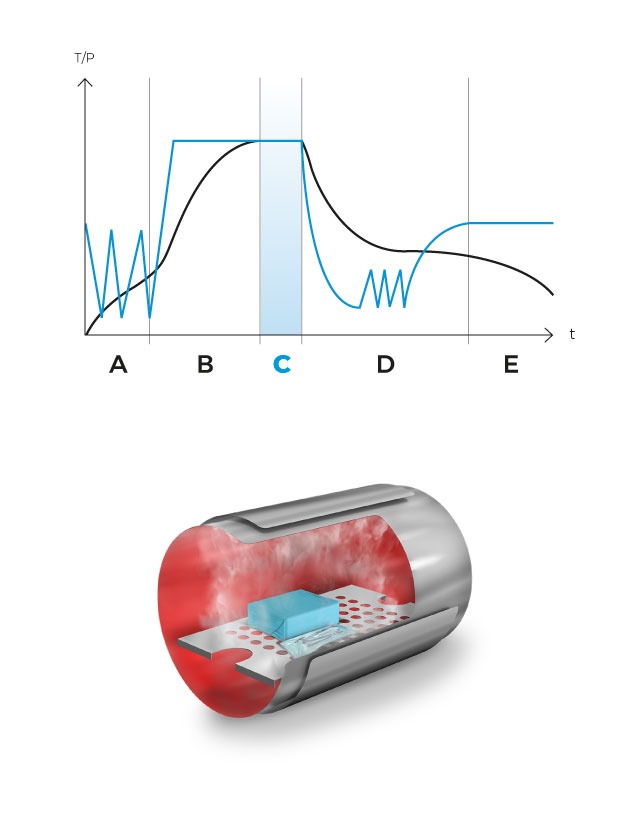

Operation

Temperature

Pressure

Operation

In the prevacuum phase, the cold air in the chamber is mechanically purged through multiple vacuum pulses. At the same time, the steam generator is activated, injecting saturated steam into the chamber. This process removes non-condensable gases from inside the chamber, eradicating the presence of cold air pockets and facilitating steam access to any surface of the load.

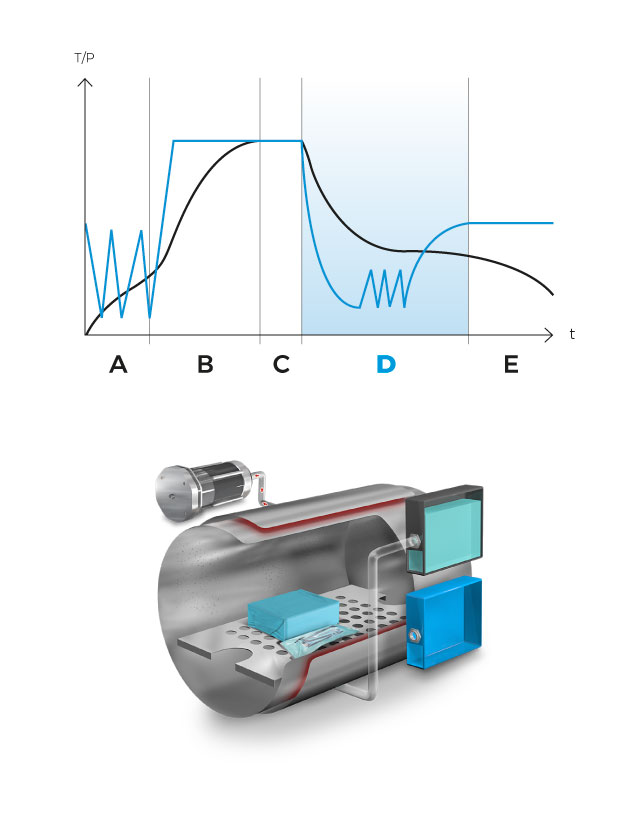

Temperature

Pressure

In this phase, the steam generator continues to inject saturated steam into the chamber until the sterilization temperature is reached.

Temperature

Pressure

Upon reaching the sterilization temperature in the medium, the sterilization phase begins and the temperature is accurately sustained for the predefined duration.

Temperature

Pressure

In programs for solid loads, after the sterilization phase is completed, the vacuum pump and heating jacket are simultaneously activated to expel all moisture and completely dry the load through the use of multiple vacuum pulses. However, in programs for liquid loads, this phase is not carried out.

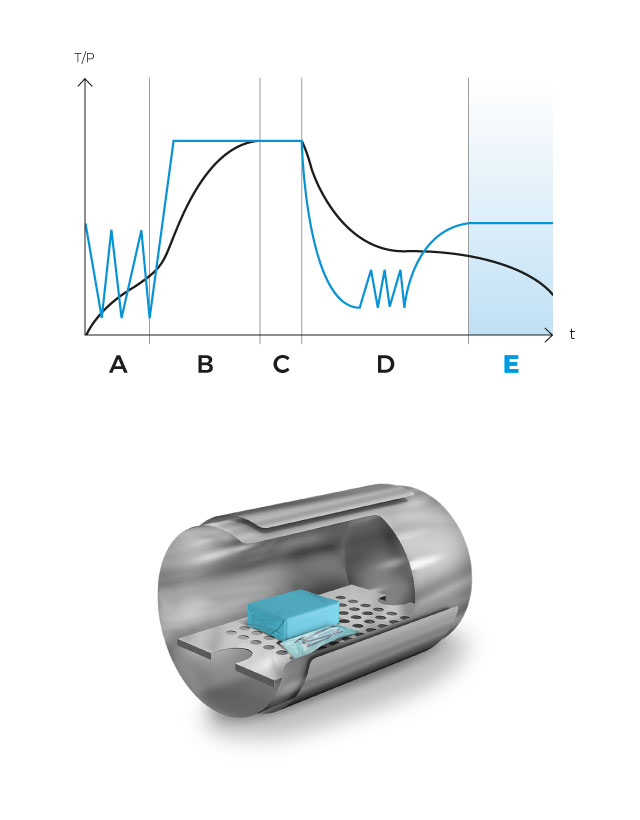

Temperature

Pressure

After the load is fully dry, a natural cooling phase begins, ending once the temperature drops to a level that's safe for handling the load without burning oneself. Then, the door can be unlocked, and the load can be taken out. In programs with agar mode activated, the preset temperature is maintained indefinitely.

Temperature

Pressure

Applications

POROUS SOLIDS AND WRAPPED OBJECTS

The mechanical purge of air using the vacuum pump facilitates the posterior penetration of steam, facilitating the sterilization of bagged items. Moreover, at the end of the cycle, they will be dry thanks to the drying function.

GLASSWARE

In programs for solid loads, the heating jacket and vacuum pump are activated at the end of the sterilization phase to completely dry the load.

OBJECTS WITH COMPLEX GEOMETRIES

The multiple initial prevacuum pulses, in conjunction with the steam generator, ensure deep steam penetration across all surfaces. Moreover, the load will be dry upon cycle completion.

SANITARY WASTE

The mechanical purge of air using the vacuum pump facilitates the posterior penetration of steam, facilitating the sterilization of bagged items. Moreover, at the end of the cycle, they will be dry thanks to the drying function.

PLASTICS AND METAL OBJECTS

In programs for solid loads, the heating jacket and vacuum pump are activated at the end of the sterilization phase to completely dry the load.

LIQUIDS AND CULTURE MEDIA

Specific programs for liquid loads. Installing a flexible probe allows for more precise sterilization of liquid loads.

Technical data

| References |

|---|

| Total/usable volume of the chamber (L) |

| Usable dimensions of the chamber (Ø max. x D mm) |

| Volume of the built-in clean water tank (L) |

| Volume of the built-in waste water tank (L) |

| External dimensions (L x D x H mm) |

| Maximum number of trays |

| Tray size (L x D mm) |

| Net weight (Kg) |

| Power (W) |

| Voltage* (V) |

| Frequency (Hz) |

| AH-21-B-MD |

| 22/21 |

| 210 x 430 |

| 6 |

| 2,6 |

| 560 x 660 x 425 |

| 5 |

| 190 x 350 |

| 65 |

| 2000 |

| 230 |

| 50/60 |

| AHS-50-B-MD |

| 55/50 |

| 360 x 400 |

| 10 |

| 6 |

| 805 x 805 x 650 |

| 5 |

| 315 x 330 |

| 114 |

| 3600 |

| 230 |

| 50/60 |

| AHS-75-B-MD |

| 79/75 |

| 360 x 600 |

| 10 |

| 6 |

| 805 x 1005 x 650 |

| 5 |

| 315 x 530 |

| 132 |

| 3600 |

| 230 |

| 50/60 |

| *Other voltages and electrical configurations available on request. |

Accessories

Flexible probe

Add a flexible probe to improve the sterilization of liquid loads.

Integrated thermal printer

It prints the program number, cycle number, evolution of parameters in the course of the cycle, date and time of execution and error messages.

Automatic water filling

Water pump designed to automate the supply of the independent water tank with purified water.

Eco-efficient water purifier

Eco-efficient direct flow water purifier without water accumulation capable of filtering 1.3 L/min with LED display.

Wire trays

Wire trays suitable for sterilization of all types of loads.

Rack for trays

Rack compatible with up to 5 trays.

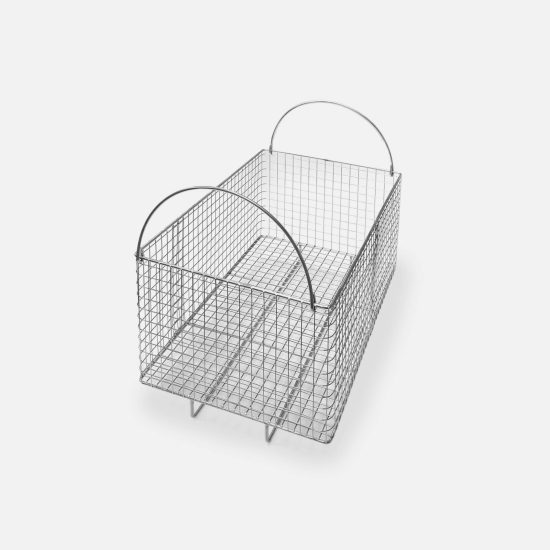

Horizontal wire baskets

Basket suitable for the sterilization of heavy and bulky loads.

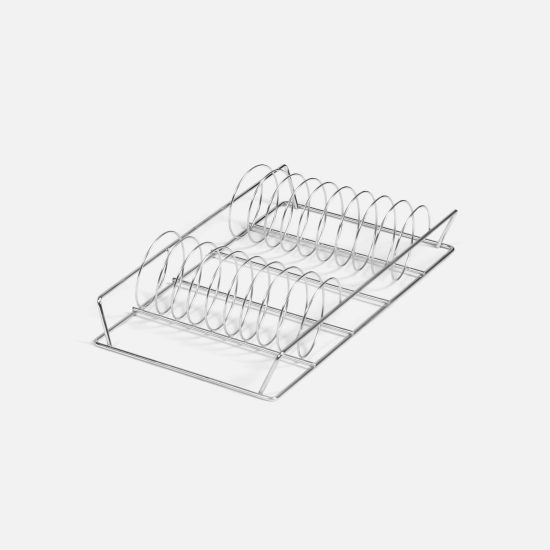

Bag support

Support suitable for the sterilization of packaged objects and bags.

Container with filter in the lid

Containers suitable for sterilization of instruments and biohazardous loads.

Desktop dot matrix printer

Prints program number, cycle number, temperature, time, dates and time of each sterilization and error messages.

SW8000 Software

Communication software between the equipment and the PC for display and recording in real time or display after each cycle.

Autoclave table

Stainless steel table with wheels with brakes. Designed to place benchtop autoclaves.

Transport trolley

Auxiliary trolley to assist in loading and unloading the autoclave.

Cable gland

Cable gland for calibration and validation procedures.

Sterilization control tape

Sterilization indicator on adhesive tape.

Pack of Bowie-Dick tests

Class B indicator printed with non-toxic inks and laminated. Tests for a proper steam penetration in porous loads.

IQ-OQ Documentation

Delivery of documentation and IQ/OQ protocol for third party autoclave qualification.

IQ-OQ-PQ Qualification

IQ/OQ/PQ autoclave qualification service performed by RAYPA.

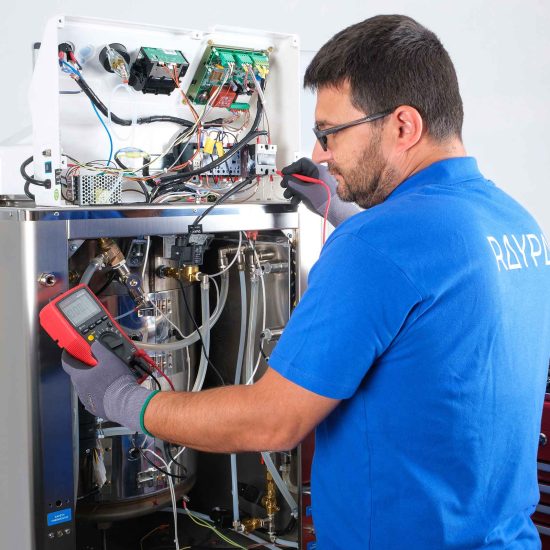

On-site commissioning & training

On-site commissioning, which includes verification of the correct operation and installation of the equipment and a training session for users on the use and maintenance of the equipment.

Remote commissioning & training

Guided remote start-up including a training session for users on the operation and maintenance of the equipment.

Maintenance contract

Regular inspection plan that includes technical inspection, probe calibration and compliance with the preventive maintenance plan, as well as tariff discounts, all performed by our expert technicians.

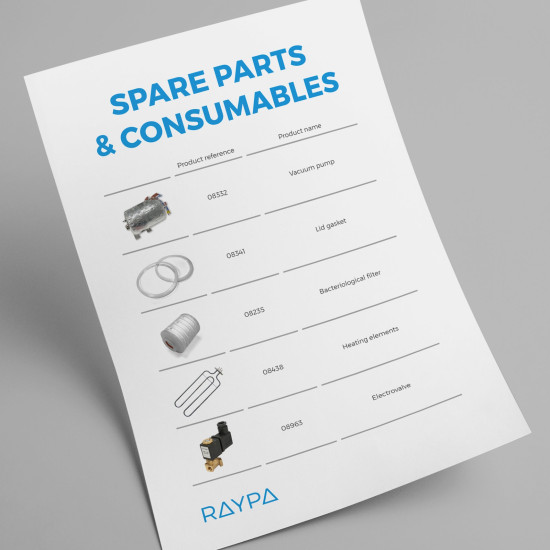

Set of consumables, spare parts and essential components

Set of original spare parts, consumables, and components, chosen specifically to adhere to each model's maintenance plan, intended to maximize equipment longevity and minimize downtime in the event of a malfunction.

Warranty extension

Extended warranty up to a total of 3 years.

You may also be interested in

Vertical medical autoclaves with prevacuums and drying

- AE-B-MD Series

- Classic Line

Vertical medical autoclaves with super-drying system

- TLV-PD-MD Series

- Top Line

Subscribe to our newsletter

"*" indicates required fields