Autoclaves > Classic line benchtop AHS-N-MD Series

Front-loading benchtop medical autoclaves without drying

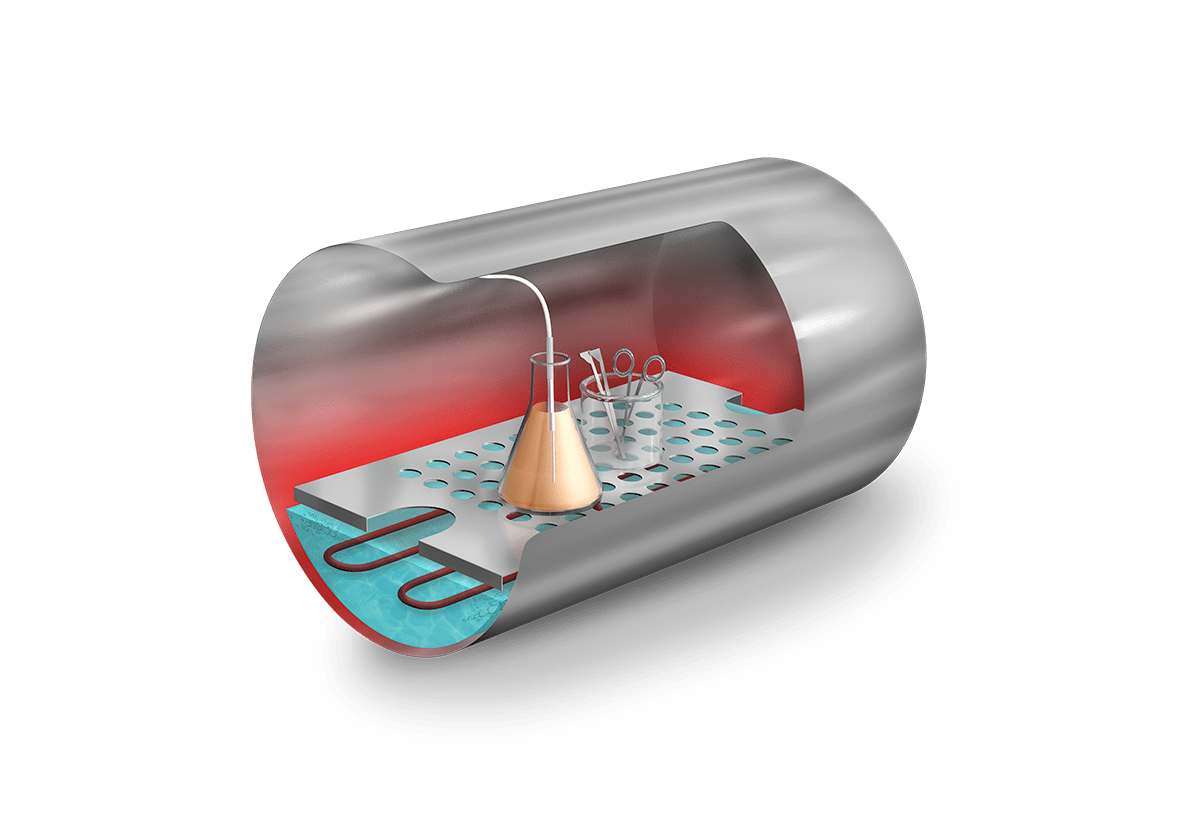

The AHS-N-MD Series front-loading benchtop medical autoclaves are designed to sterilize a wide variety of medical materials in an economical and straightforward manner.

- Economical, cost-effective, and with robust performance

- Limited consumption of resources

- Excellent construction materials

Front-loading benchtop medical autoclaves without drying

The AHS-N-MD Series benchtop medical autoclaves meet the fundamental sterilization needs of medical facilities to increase productivity and simplify sterilization operations.

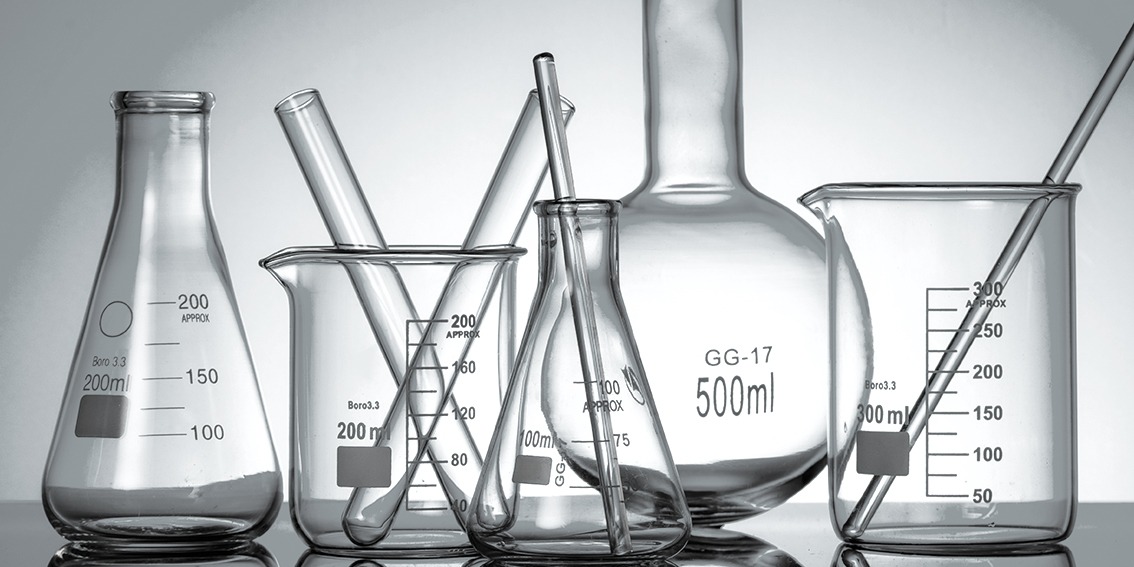

They are designed for sterilization of a wide range of solid and liquid loads, including glass, plastics, metal utensils, liquids and other medical items.

Suitable for medical use, they are optimized for easy operation, include many safety features to protect users in their daily routine and are easy to install as they are plug and play.

Economical, resilient and limited resource consumption

Built using high-quality construction materials, they feature a sterilization chamber made of exceptionally resistant AISI-316L stainless steel. The components are sourced from top-tier manufacturers. Limited consumption of water, energy and operator time.

Compact design and easy installation

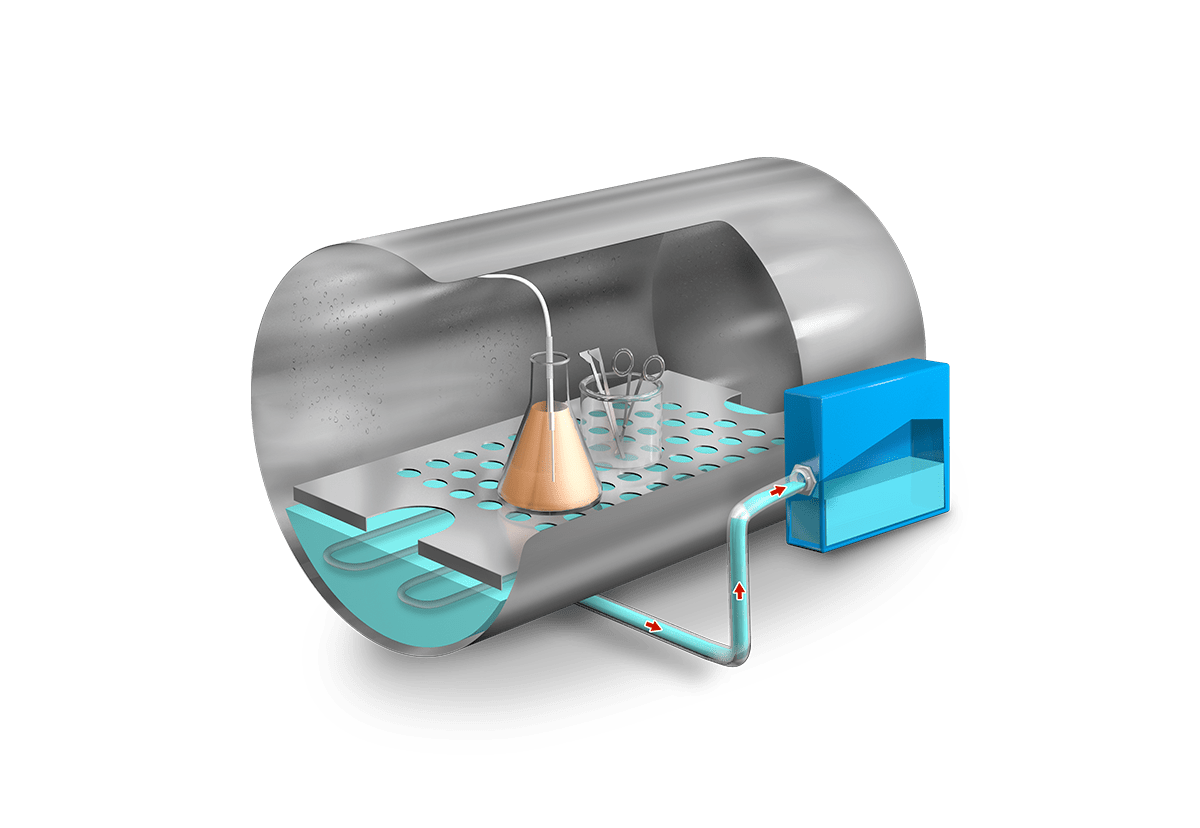

Compact and desktop design. They have an integrated independent water tank. No specific connections are required for their installation, they are plug and play equipment, they simply need an electrical connection.

Customize with a range of accessories

Choose the model and type of support that best suits your needs. Install a flexible probe for more accurate and safe sterilization of liquids. Record and analyze your processes with dedicated software or an embedded printer.

Operation

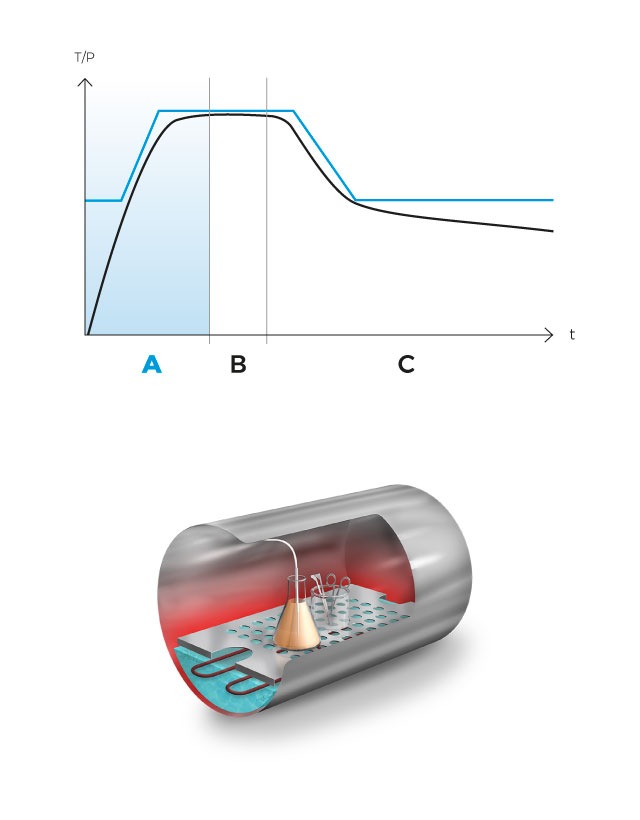

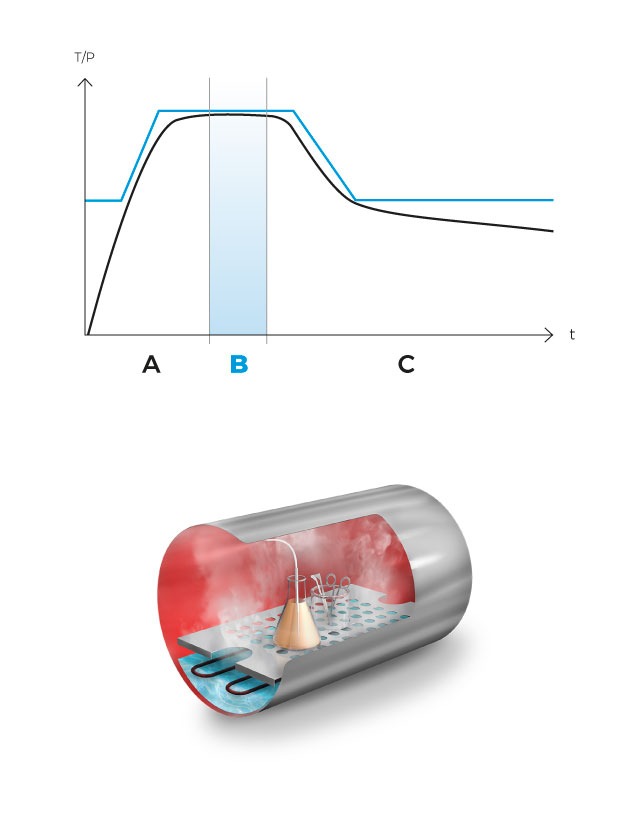

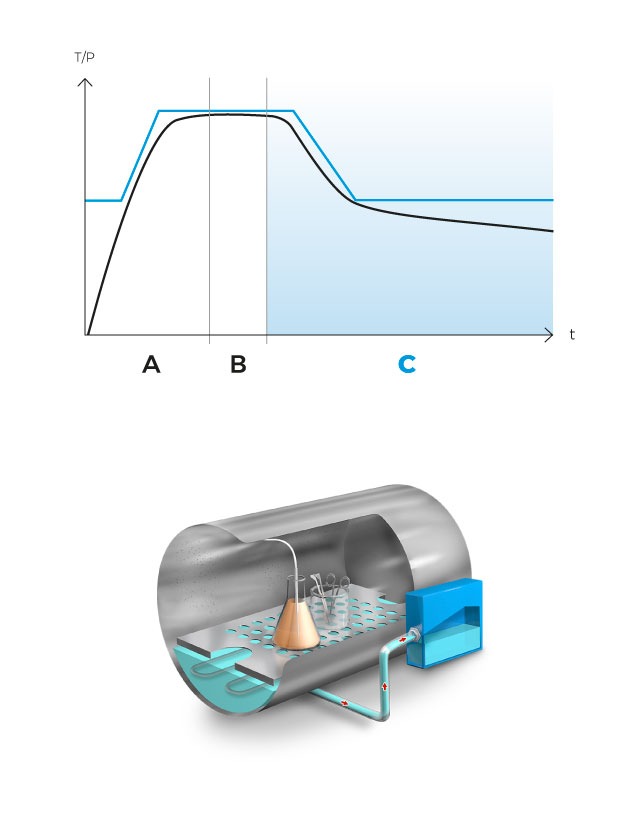

In the heating phase, powerful electric heating elements dramatically heat the water to produce saturated steam. When the sterilization temperature is reached, the sterilization phase begins and the temperature is accurately maintained during the sterilization time.

At the end of the sterilization phase, a natural cooling phase begins. In the solids programs, the discharge can be forced manually by means of a push button to reduce the duration of this phase. In the programs for liquids there is the possibility to regulate the cycle by heart probe and to use the agar mode to maintain a constant chamber temperature and avoid gelling of the culture medium.

Temperature

Pressure

Operation

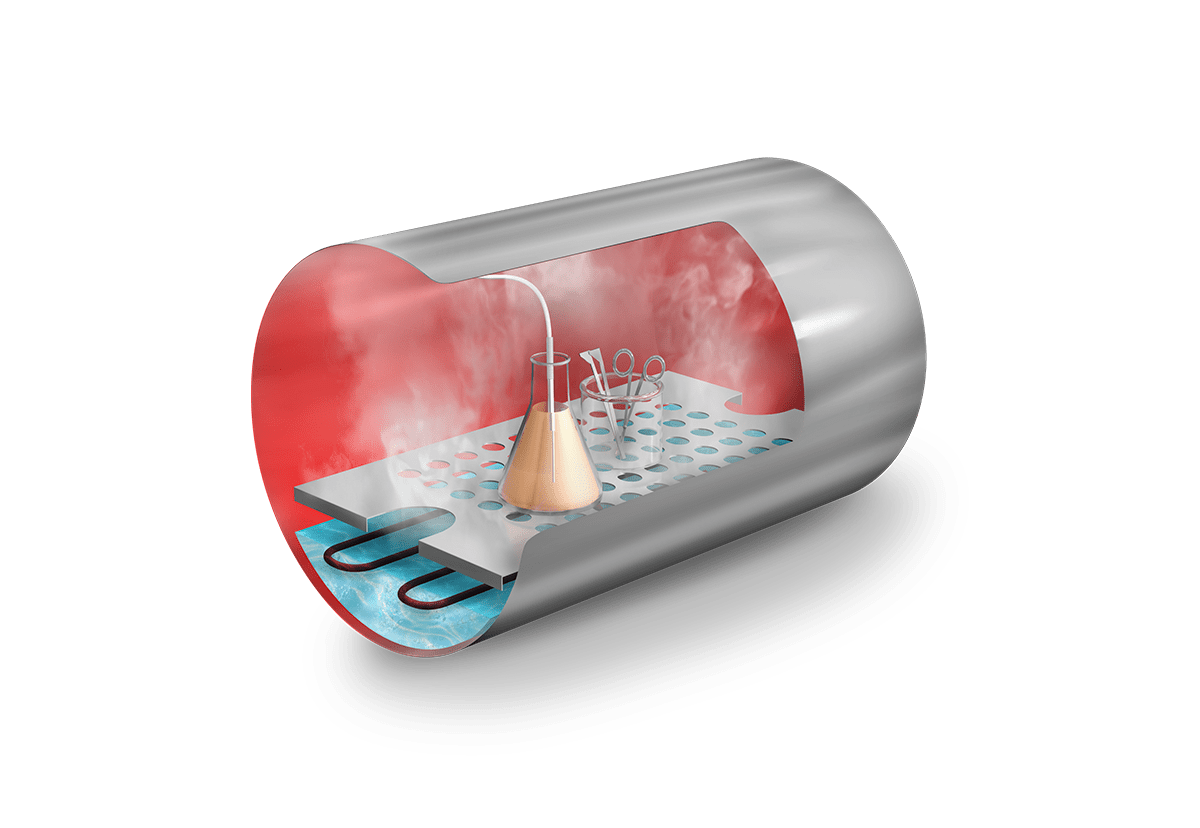

The heating elements heat up water to produce saturated steam, which expels the cold air outward until the sterilization temperature is achieved in the chamber.

Temperature

Pressure

Upon reaching the sterilization temperature in the medium, the sterilization phase begins and the temperature is accurately sustained for the predefined duration.

Temperature

Pressure

After completion of sterilization, a final natural cooling phase begins until a safe temperature is reached. Optionally, the agar mode can be configured to maintain a constant temperature.

Temperature

Pressure

Applications

METALLIC OBJECTS

For a faster cooling phase in solids sterilization cycles, a quick unsteaming can be carried out through a manual valve and thus shorten the duration of the cooling phase.

PLASTICS

Activating the rapid steam release button allows for faster cooling in solid loads.

GLASSWARE

Activating the rapid steam release button allows for faster cooling in solid loads.

SANITARY WASTE

For this application, the sterilization time should be extended and chemical and/or biological tests should be used to validate the correct sterilization of the load.

LIQUIDS AND CULTURE MEDIA

The agar mode maintains the temperature and prevents the culture media from gelling. Installing a flexible probe allows for more precise sterilization of liquid loads.

Technical data

| References |

|---|

| Total/usable volume of the chamber (L) |

| Usable dimensions of the chamber (Ø max. x D mm) |

| Volume of the built-in water tank (L) |

| External dimensions (L x D x H mm) |

| Maximum number of trays |

| Tray size (L x D mm) |

| Net weight (Kg) |

| Power (W) |

| Voltage* (V) |

| Frequency (Hz) |

| AH-21-N2-MD |

| 22/21 |

| 210 x 430 |

| 6 |

| 560 x 680 x 425 |

| 4 or 5 |

| 190 x 350 |

| 45 |

| 2000 |

| 230 |

| 50/60 |

| AHS-50-N-MD |

| 55/50 |

| 360 x 400 |

| 10 |

| 805 x 805 x 650 |

| 5 |

| 315 x 330 |

| 93 |

| 2800 |

| 230 |

| 50/60 |

| AHS-75-N-MD |

| 79/75 |

| 360 x 600 |

| 10 |

| 805 x 1005 x 650 |

| 5 |

| 315 x 530 |

| 110 |

| 3200 |

| 230 |

| 50/60 |

| *Other voltages and electrical configurations available on request. |

Accessories

Flexible probe

Add a flexible probe to improve the sterilization of liquid loads.

Integrated thermal printer

It prints the program number, cycle number, evolution of parameters in the course of the cycle, date and time of execution and error messages.

Water distiller

Forced air water distiller with stainless steel interior, 4L capacity and 1,5L/h distillation volume.

Wire trays

Wire trays suitable for sterilization of all types of loads.

Rack for trays

Rack compatible with up to 5 trays.

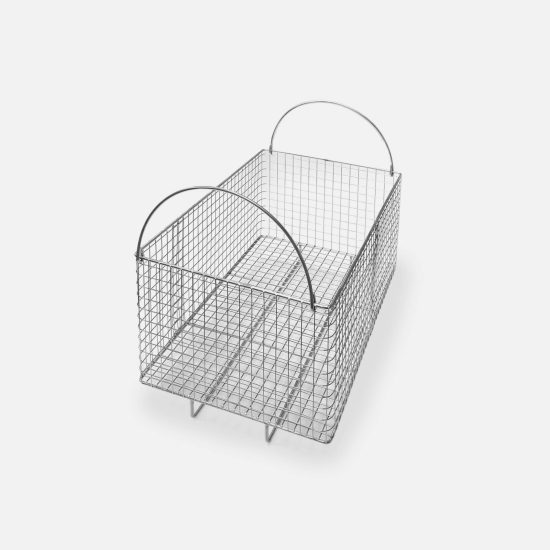

Horizontal wire baskets

Basket suitable for the sterilization of heavy and bulky loads.

Bag support

Support suitable for the sterilization of packaged objects and bags.

Desktop dot matrix printer

Prints program number, cycle number, temperature, time, dates and time of each sterilization and error messages.

SW7000 Software

Software to analyze and record cycles

Autoclave table

Stainless steel table with wheels with brakes. Designed to place benchtop autoclaves.

Transport trolley

Auxiliary trolley to assist in loading and unloading the autoclave.

Cable gland

Cable glands for calibration and validation operations

Sterilization control tape

Sterilization indicator on adhesive tape

IQ-OQ Documentation

Delivery of documentation and IQ/OQ protocol for third party autoclave qualification.

IQ-OQ-PQ Qualification

IQ/OQ/PQ autoclave qualification service performed by RAYPA.

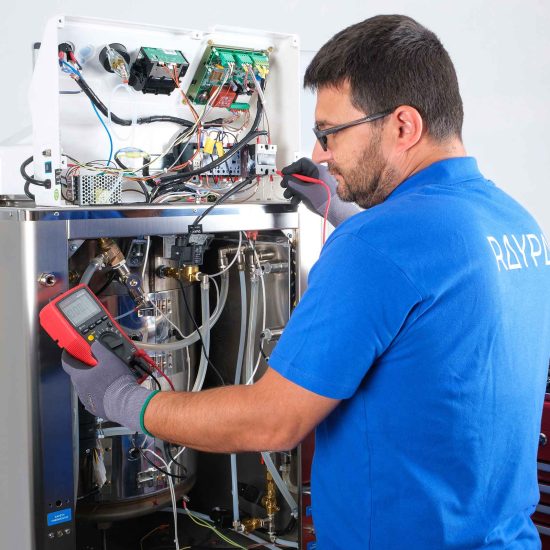

On-site commissioning & training

On-site commissioning, which includes verification of the correct operation and installation of the equipment and a training session for users on the use and maintenance of the equipment.

Remote commissioning & training

Guided remote start-up including a training session for users on the operation and maintenance of the equipment.

Maintenance contract

Regular inspection plan that includes technical inspection, probe calibration and compliance with the preventive maintenance plan, as well as tariff discounts, all performed by our expert technicians.

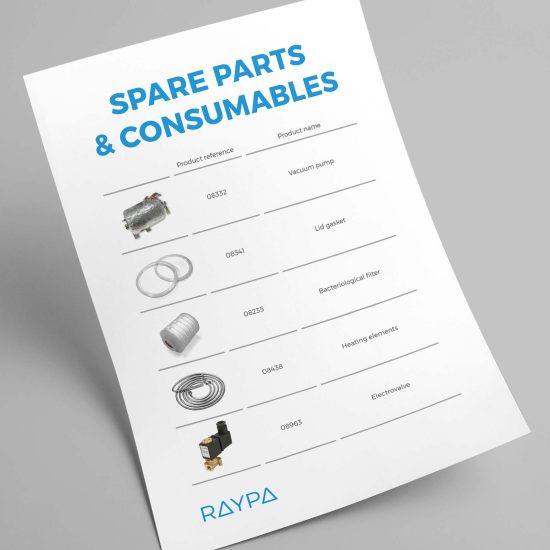

Set of consumables, spare parts and essential components

Set of original spare parts, consumables, and components, chosen specifically to adhere to each model's maintenance plan, intended to maximize equipment longevity and minimize downtime in the event of a malfunction.

Warranty extension

Extended warranty up to a total of 3 years

You may also be interested in

Front-loading Benchtop Medical Autoclaves with Drying

- AHS-DRY-MD Series

- Classic Line

Benchtop medical autoclaves with prevacuums and drying

- AHS-B-MD Series

- Classic Line

Vertical medical autoclaves without drying

- AES-MD Series

- Classic Line

Vertical medical autoclaves with prevacuums and drying

- AE-B-MD Series

- Classic Line

Vertical medical autoclaves with drying

- AE-DRY-MD Series

- Classic Line

Subscribe to our newsletter

"*" indicates required fields