Autoclaves for sterilization processes in the food industry

Within the food processing industry, autoclaves are instrumental in ensuring the sterilization and preservation of food products. This process encompasses the thermal treatment of both canned goods and broadly, any food products necessitating thermal processing at temperatures surpassing 100 degrees Celsius. The goal is always the same: to drastically reduce or altogether eliminate microbial populations within the product.

This process significantly extends the shelf life of canned or packaged food, to the extent that it can last for several years under optimal conditions. This is why most canned foods have such a long shelf life.

The operation of a food autoclave closely mirrors those employed in various other industrial sectors. Nonetheless, within the food industry, its utilization is mandated for the processing of a broad spectrum of food products packaged in glass and metal containers, such as canned seafood, fish, vegetables, fruits, or ready meals.

This requirement is instituted due to the fact that autoclave sterilization of packaged foods ensures the preservation of their contents by guaranteeing the comprehensive eradication of all microorganisms, thereby safeguarding consumer health and expanding substantially the shelf life of the food product.

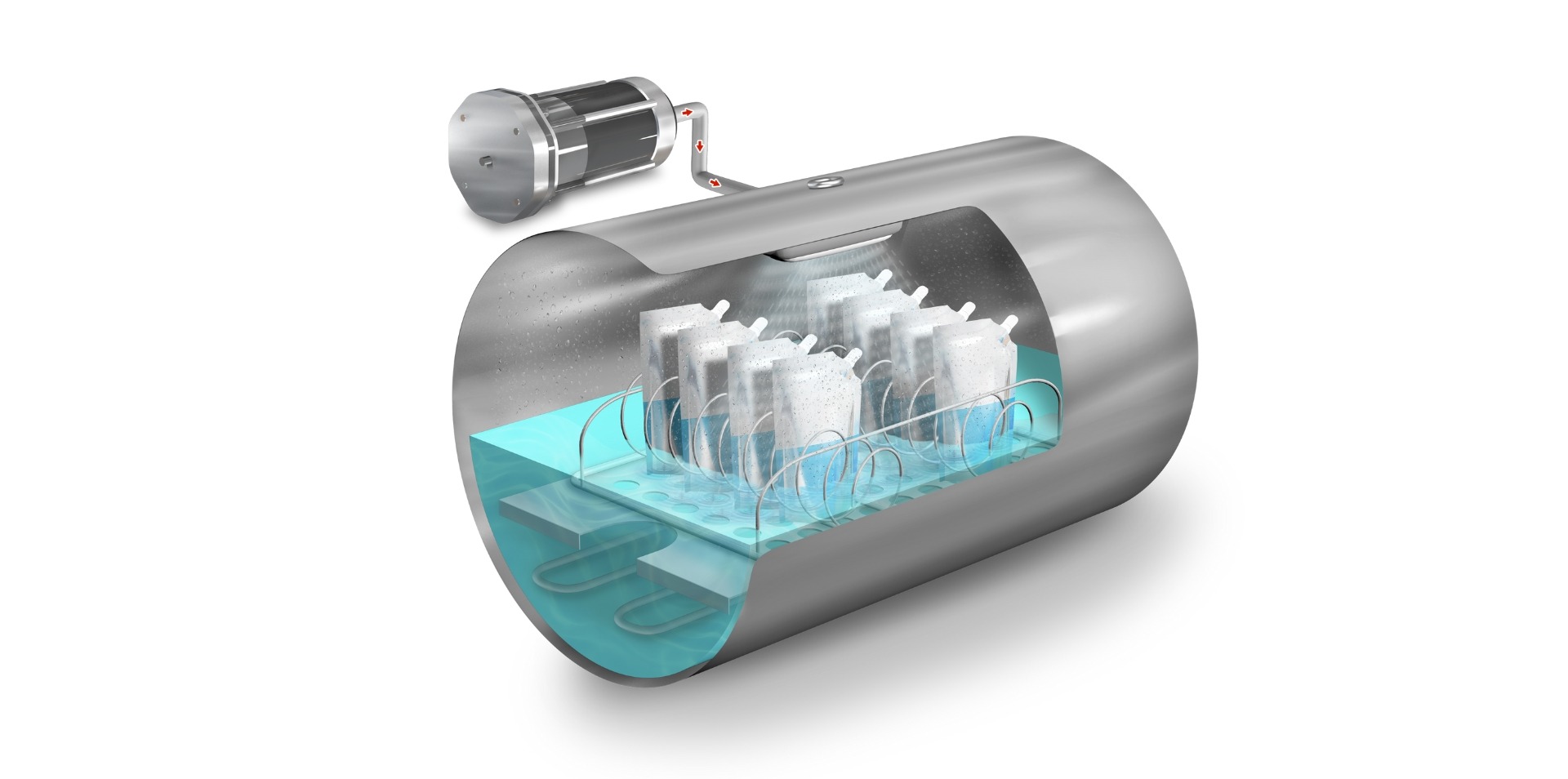

The operating principle of an autoclave involves the use of steam under pressure. When water is heated and turns into steam, it occupies a much larger volume than in its liquid state. By confining this steam in a sealed environment, such as that of an autoclave, a high pressure is induced. This increase in pressure, coupled with the fact that the steam can reach temperatures significantly higher than 100°C, facilitates an efficient transfer of energy to the material being sterilized, resulting in a rapid increase in the temperature of the load.

Steam generation constitutes an integral component of the sterilization process in autoclaves, achievable through various means such as integrated electric heating elements, an internal steam generator, or an external steam boiler, contingent upon the specific design and model of the autoclave. The process involves heating of water to the point where it becomes saturated steam, distinguished by its improved thermal characteristics that facilitate a quicker heat transfer.

Once the appropriate steam is generated, it completely surrounds the food in its respective containers, ensuring that heat is uniformly transmitted to every corner. The superior effectiveness of moist heat in sterilization processes stems from the steam’s ability to transfer heat more efficiently than dry heat.

Achieving precise control over pressure and temperature is fundamental in the operation of autoclaves, which are outfitted with sensors and valves designed for the real-time monitoring and adjustement of these critical parameters. The increase in pressure directly affects the thermal properties of steam, leading to a rise in its temperature and a consequent reduction in the required exposure time, a crucial factor for the complete inactivation of all microorganisms without compromising the quality of the processed food. It is important to note that the specific settings for the duration and temperature of the sterilization cycle are intricately tailored to the particularities of the food item being sterilized, the size and shape of the container, and the resilience and characteristics of the target microorganisms, to achieve optimal sterilization efficacy.

A critical yet frequently underestimated component of the sterilization process, specially in porous items or wrapped objects, is the elimination of cold air from the chamber prior to sterilization. The presence of air can serve as an insulating barrier, hindering the efficient transfer of heat. Certain models of our autoclaves are capable of performing a prevacuum phase designed to address this issue. During this step, air is evacuated from the chamber before steam introduction, thereby facilitating even and consistent sterilization throughout the load.

Subsequent to the exposure of food to predefined temperature and pressure conditions for a designated duration, it is essential to cool down the food as fast as possible to prevent overcooking and maintain its organoleptic attrbiutes. This rapid cooling process in the autoclave is achieved through a shower water system and a counterpressure system. The interaction between these two mechanisms facilitates efficient cooling of the load while preventing the risk of container breakage.

Autoclaves for the food industry of certified quality

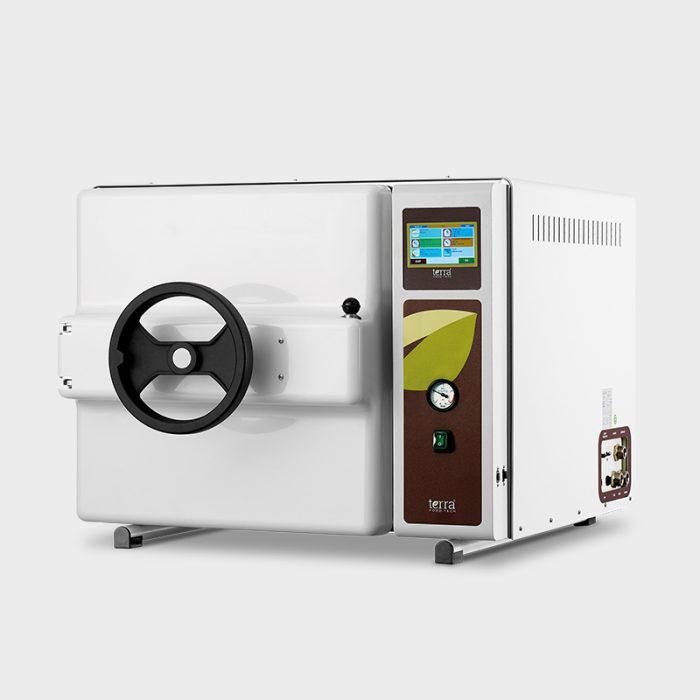

While TERRA Food-Tech® autoclaves for food production are outfitted with the necessary technology to pasteurize or sterilize all types of packaged food items, ensuring their suitability for food production applications. Conversely, RAYPA autoclaves are tailored for the sterilization of laboratory essentials such as utensils, glassware, culture media, and laboratory waste. These functions are particularly vital in research and development (R&D) laboratories and quality control departments prevalent in the food industry sector.

At RAYPA and TERRA Food-Tech®, we have a wide variety of autoclaves of certified quality. Our product catalog includes an extensive range of models for the food industry, belonging to the AES, AE-DRY, AHS-N, CFS-V and CFS-H series from the Classic Line range.

Their robust construction, outstanding value and straightforward installation make them an exceptional choice for laboratories of the food industry.

In addition to a diverse range of models, we provide a wide selection of accessories for the food sector, including custom baskets and trays, additional flexible probes, specific racks, transport carts and lifting cranes, among others.

The reliability of sterilization equipment is crucial for both process safety and effectiveness. This reliability is also fundamental to ensure quality in both production and the resulting product. That is why for over 45 years, all our autoclaves for the food industry have been designed and constructed at our facilities in Barcelona, reflecting our commitment to quality and our extensive experience.

This equipment undergoes extensive testing to ensure its quality and to comply with the most stringent regulations and standards, including the European Pressure Equipment Directive (PED). By adopting this approach, we pursue the highest levels of production excellence and ensure the safety of our products.

At RAYPA, we provide comprehensive solutions tailored to meet our customers’ sterilization requirements. With our wide selection of autoclaves and the expert advice of our team, we assist you in finding the equipment that best suits your requirements.

For more detailed and customized guidance on choosing the ideal autoclave for your laboratory, do not hesitate to contact our experts. Working together, we can identify and provide a solution that ensures both efficiency and safety in all your sterilization operations.

Why RAYPA?

GLOBAL REACH

With half a century of experience, we have a lengthy list of satisfied customers around the world. Currently, we export 85% of our annual turnover and have a stable network of distributors in over 100 countries.

EFFICIENT TECHNICAL SERVICE

Our team of highly qualified technicians and engineers is expert in our products. If you experience a technical issue, it will be our priority to rectify it. When you purchase a RAYPA unit, you’re guaranteed top-level support and technical assistance.

EXPERT MANUFACTURER

RAYPA is a global leader in manufacturing laboratory autoclaves. Each of our autoclaves is designed and built entirely at our facilities in Barcelona, ensuring the highest levels of production excellence.

FULL AND CUSTOMIZABLE RANGE

We offer an extensive portfolio of laboratory autoclaves to cover multiple applications and market segments. Discover the combination of autoclave model and accessories that best fits your needs within our 11 series and 35 available models.

INNOVATION AND QUALITY

Our products feature advanced technology, ongoing innovation, superior construction quality, and are designed for a long service life. Our technical and engineering staff works tirelessly every day to optimize our products and exceed our customers’ expectations.

COMPREHENSIVE CONSULTATION

Our team of specialists assesses each project and provides guidance to clients on the option that best suits their requirements. After the sale, we offer training on the use and recommended maintenance of each unit to ensure its optimal operation and extend its lifespan.