Sterilizing pilot batches with an autoclave

In sectors such as pharmaceuticals and food manufacturing, new products undergo various tests to assess their behavior and stability, considering their composition, packaging, and components. It’s a standard procedure to produce several test batches with varied formulations to determine the optimal recipe.

In the case of both food and pharmaceutical items, tests on these batches occur before, during and after the process of sterilization or pasteurization. For those requiring sterilization, the use of an autoclave is typically the method of choice. It is worth noting, though, that while autoclaves are capable of pasteurization, there are specific devices better suited for this purpose in certain contexts.

These small-scale tests, aimed at saving resources, enable lab technicians to thoroughly assess different characteristics of the products, including taste, texture, color, and smell. In addition, the microbial stability of each version, like its shelf life or expiration date after sterilization, is carefully scrutinized. Upon identifying and gaining approval for a product variant with the best attributes, it can move forward to large-scale manufacturing.

An autoclave for pilot batches typically has a capacity of under 125 liters, adequate for the majority of testing requirements. Its compact design ensures it can be efficiently installed and operated even in laboratories where space is at a premium. Beyond their role in research and development, these autoclaves are crucial in a company’s quality assurance or production divisions, underscoring their wide-ranging utility and significance in the product development process.

Autoclaves for pilot batches of certified quality

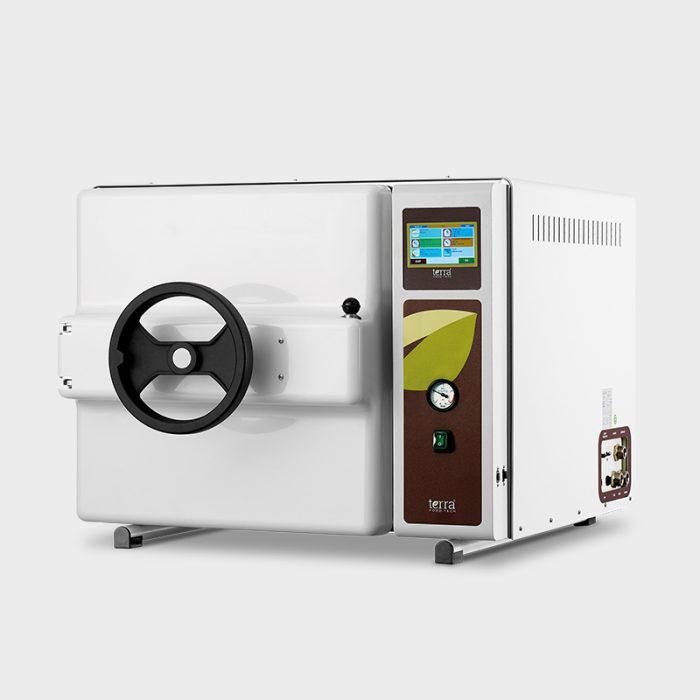

At RAYPA, we offer a wide selection of autoclaves for pilot batches. Our product catalog features an extensive variety of models, including the CFS-V and CFS-H Series from TERRA Food-Tech® and the TLV-FA Series from the Top Line range.

Their superior performance, versatility, robust construction and professional traceability make them an excepcional choice for pilot batches tests.

In addition to the diverse range of models, a comprehensive selection of accessories is offered, such as cloud-based management software, FDA compliance, up to two flexible probes, specific racks, qualification services and ticket printers. These tools enhance the ability to monitor and validate the effectiveness of sterilization processes conducted within the autoclave. This aspect is particularly crucial in stringently regulated fields like the pharmaceutical sector.

Trust in sterilization equipment is essential for conducting safe and successful experiments, as well as for upholding quality in laboratories and industrial settings. That is why for over 45 years, all our autoclaves for pilot batches have been designed and constructed at our facilities in Barcelona, reflecting our commitment to quality and our extensive experience.

This equipment undergoes extensive testing to ensure its quality and to comply with the most stringent regulations and standards, including the European Pressure Equipment Directive (PED).

Furthermore, they are capable of operating in FDA, GMP, and GLP environments and adhere to FDA 21 CFR Part 11. With this, we aim for the highest levels of excellence in production and guarantee the safety and traceability of our products.

At RAYPA, we provide comprehensive solutions tailored to meet our customers’ sterilization requirements. With our wide selection of autoclaves and the expert advice of our team, we assist you in finding the equipment that best suits your requirements.

For more detailed and customized guidance on choosing the ideal autoclave for your laboratory, do not hesitate to contact our experts. Working together, we can identify and provide a solution that ensures both efficiency and safety in all your sterilization operations.

Why RAYPA?

GLOBAL REACH

With half a century of experience, we have a lengthy list of satisfied customers around the world. Currently, we export 85% of our annual turnover and have a stable network of distributors in over 100 countries.

EFFICIENT TECHNICAL SERVICE

Our team of highly qualified technicians and engineers is expert in our products. If you experience a technical issue, it will be our priority to rectify it. When you purchase a RAYPA unit, you’re guaranteed top-level support and technical assistance.

EXPERT MANUFACTURER

RAYPA is a global leader in manufacturing laboratory autoclaves. Each of our autoclaves is designed and built entirely at our facilities in Barcelona, ensuring the highest levels of production excellence.

FULL AND CUSTOMIZABLE RANGE

We offer an extensive portfolio of laboratory autoclaves to cover multiple applications and market segments. Discover the combination of autoclave model and accessories that best fits your needs within our 11 series and 35 available models.

INNOVATION AND QUALITY

Our products feature advanced technology, ongoing innovation, superior construction quality, and are designed for a long service life. Our technical and engineering staff works tirelessly every day to optimize our products and exceed our customers’ expectations.

COMPREHENSIVE CONSULTATION

Our team of specialists assesses each project and provides guidance to clients on the option that best suits their requirements. After the sale, we offer training on the use and recommended maintenance of each unit to ensure its optimal operation and extend its lifespan.