The canning sterilization process by autoclaving

The canning industry plays a crucial role in the food sector, primarily focusing on ensuring the safety and longevity of its products. Sterilization stands out as a fundamental process in this field, directly influencing the quality and safety of preserved foods.

Canned products encompass a broad spectrum, from fruits and vegetables to meats and fish, packaged in various types of containers such as glass, tin, plastic, and innovative pouches. The hermetic sealing of these products necessitates stringent sterilization, particularly the need to achieve temperatures exceeding 110 degrees Celsius (230 degrees Fahrenheit) to effectively inactivate all microorganisms.

While pasteurization serves as a thermal method to reduce the microbial load in foods through heating, it falls short of completely eradicating all microorganisms, especially spores. On the other hand, commercial sterilization, typically conducted in autoclaves, provides a more thorough solution by entirely eliminating microorganisms and their spores, thereby ensuring the product’s safety over a significantly extended shelf life.

Autoclaves emerge as a crucial instrument in the sterilization process, utilizing steam under specific pressure and temperature to eradicate harmful microorganisms while largely maintaining the food’s sensory qualities.

It’s a misconception that autoclaves are solely for the use of large-scale canning operations. In reality, small enterprises, restaurants, and even small-scale or gourmet producers can significantly enhance their product quality and safety by incorporating autoclaves into their processes, irrespective of their production volume.

Beyond serving as a safeguard against pathogenic microorganisms, sterilization through autoclaves is often a legal mandate in numerous jurisdictions for the sale of canned goods. Non-sterilized products are not permitted for sale, a regulation put in place to ensure consumer safety by guaranteeing that all canned products are devoid of harmful microorganisms and are safe for consumption.

The application of autoclave sterilization allows canning businesses to significantly prolong the shelf life of their offerings, extending well past the conventional two months, and eliminates the need for refrigeration until the product is opened.

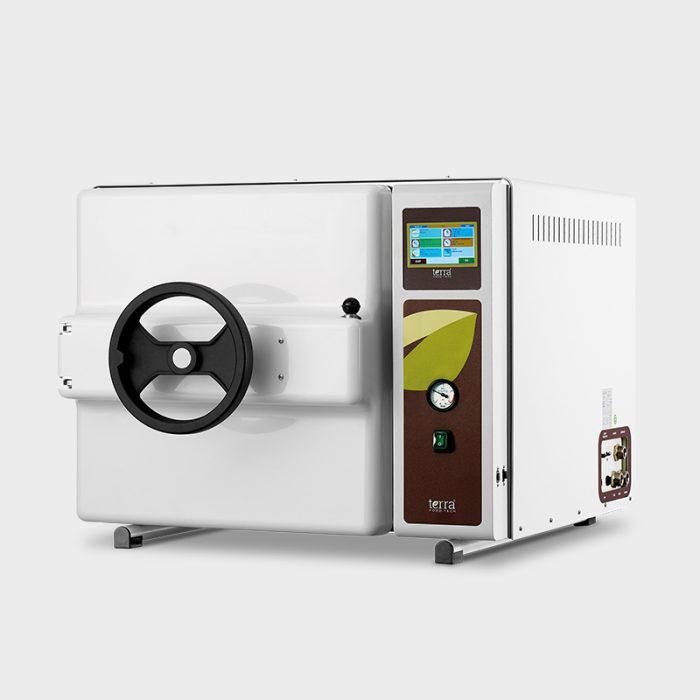

Certified quality autoclaves for canning

The selection of an autoclave for canning purposes is influenced by the unique requirements of each operation. Large-scale canneries might find top-loading vertical autoclaves more appropriate due to their capacity and efficiency, while front-loading autoclaves could be better suited for smaller enterprises, given their compact design and ease of use. Factors to consider include the volume of production, space constraints, setup needs, and the particular properties of the items being sterilized.

At RAYPA, our commitment is to provide a diverse array of high-quality autoclaves tailored for the canning industry. Our lineup includes models from the CFS-V and CFS-H Series trademarked under the brand TERRA Food-Tech®, designed to meet a wide range of sterilization needs.

These units are not only built to last but also offer excellent value and are designed for easy installation, making them a top choice for canning facilities of all sizes.

Beyond the autoclaves themselves, we supply a comprehensive range of accessories to enhance your sterilization setup. This includes customizable racks, a basket lifting crane for ease of handling, perforation kits suitable for various container types, a water softener to prolong the lifespan of the equipment, specialized software for operational precision, and ticket printers for record-keeping and compliance.

Reliability in sterilization equipment is crucial for both the safety and effectiveness of experiments. This reliability is also essential to ensure quality in laboratories and production areas. That is why for over 45 years, all our autoclaves for canning have been designed and constructed at our facilities in Barcelona, reflecting our commitment to quality and our extensive experience.

This equipment undergoes extensive testing to ensure its quality and to comply with the most stringent regulations and standards, including the European Pressure Equipment Directive (PED). By adopting this approach, we pursue the highest levels of production excellence and ensure the safety of our products.

At RAYPA, we provide comprehensive solutions tailored to meet our customers’ sterilization requirements. With our wide selection of autoclaves and the expert advice of our team, we assist you in finding the equipment that best suits your requirements.

For more detailed and customized guidance on choosing the ideal autoclave for your laboratory, do not hesitate to contact our experts. Working together, we can identify and provide a solution that ensures both efficiency and safety in all your sterilization operations.

Why RAYPA?

GLOBAL REACH

With half a century of experience, we have a lengthy list of satisfied customers around the world. Currently, we export 85% of our annual turnover and have a stable network of distributors in over 100 countries.

EFFICIENT TECHNICAL SERVICE

Our team of highly qualified technicians and engineers is expert in our products. If you experience a technical issue, it will be our priority to rectify it. When you purchase a RAYPA unit, you’re guaranteed top-level support and technical assistance.

EXPERT MANUFACTURER

RAYPA is a global leader in manufacturing laboratory autoclaves. Each of our autoclaves is designed and built entirely at our facilities in Barcelona, ensuring the highest levels of production excellence.

FULL AND CUSTOMIZABLE RANGE

We offer an extensive portfolio of laboratory autoclaves to cover multiple applications and market segments. Discover the combination of autoclave model and accessories that best fits your needs within our 11 series and 35 available models.

INNOVATION AND QUALITY

Our products feature advanced technology, ongoing innovation, superior construction quality, and are designed for a long service life. Our technical and engineering staff works tirelessly every day to optimize our products and exceed our customers’ expectations.

COMPREHENSIVE CONSULTATION

Our team of specialists assesses each project and provides guidance to clients on the option that best suits their requirements. After the sale, we offer training on the use and recommended maintenance of each unit to ensure its optimal operation and extend its lifespan.