The importance of proper bioreactor sterilization

A bioreactor is a vessel or system in which the cultivation of a biological mass is carried out under strictly controlled environmental conditions. The most common use cases include the cultivation of microorganisms and animal or plant cells. These instruments are designed to control and manage optimal environmental conditions for growth, such as temperature, nutrient concentration, gas flow, dissolved oxygen concentration, pH and agitation.

Bioreactors are used in a wide variety of industries, ranging from the manufacturing of pharmaceuticals and vaccines for the pharmaceutical industry, the development of innovative oncological treatments such as CAR-T therapies through genetic engineering in hospital environments, to the cultivation of bacteria and fungi for the production of food and beverages in the food industry.

To ensure that cultures are not contaminated, it is essential that bioreactors are properly sterilized prior to initiating any cultivation process. The lack of complete sterilization of the bioreactor and its components can seriously compromise the quality and purity of the final product. This is due to several causes, such as competition for nutrients by microbiological contamination, modification of the properties of the culture media by the growth of other microorganisms, or even inhibition of the development of the desired strain. These factors can result in lower yields or failure of the process.

This is where RAYPA autoclaves with pre-vacuum and drying come into play, machines specifically designed for the sterilization of materials and instruments with complex geometries and cavities, such as bioreactors.

To properly sterilize objects of this nature, autoclaves must use a pre-vacuum system that completely removes cold air from inside the object before introducing saturated steam at high temperature and pressure. The effectiveness of an autoclave in sterilizing a bioreactor lies in its ability to first remove non-condensable gases and, subsequently, inject high-pressure steam. This steam is distributed evenly, reaching all surfaces and corners of the bioreactor, thus ensuring that both the object and its components are completely sterilized.

In addition, considering the high sensitivity of cellular and microbiological cultures, it is crucial to use autoclaves that generate high-quality steam from purified water. This ensures that minimal amounts of salts and contaminants are transferred during each bioreactor sterilization cycle.

Although bioreactors are available in industrial versions, laboratory-scale multipurpose models can be completely sterilized in autoclaves, just like all elements and substances that interact with the bioreactor, such as probes, tubes, culture media and solutions.

The process of sterilizing bioreactors by autoclaving

To effectively sterilize a bioreactor with an autoclave, a meticulous process is followed. Prior to sterilization, it is essential to verify that the bioreactor is clean and free of any residual matter. All components and liquids that can be removed and need sterilization are disassembled and prepared for the process, being thoroughly washed. Then, the bioreactor and its components are placed in the autoclave. It is crucial to ensure that steam circulates without obstructions around and inside the tubes and compartments of the device. For this, valves must be opened and pipelines kept clear.

Initially, the autoclave activates its pre-vacuum system, executing three vacuum pulses of -0.8 Bars to expel the air from the chamber and the interior of the object to be sterilized. After each vacuum pulse, the steam generator introduces saturated steam, balancing the internal pressure to atmospheric and, at the same time, raising the internal temperature and pressure to approximately 121°C (250°F) and 2.5 bars. This pre-vacuum and heating stage usually lasts between 20 and 30 minutes, although the time can vary depending on the size of the autoclave and the type of bioreactor.

Once the pre-vacuum and heating phase is completed, the autoclave begins the crucial stage: sterilization. It is vital that during this phase the temperature is kept stable and exact, without variations, as any change could compromise the effectiveness of the sterilization process. When sterilizing a bioreactor containing culture media, it is necessary to previously validate the process using temperature probes to assess lethality, in addition to chemical and biological indicators. It is important to consider that the sterilization of large liquid volumes requires longer exposure periods.

After completing the sterilization stage, the autoclave is cooled and, in the case of working with empty bioreactors, the drying phase begins. During this stage, the vacuum pump and the heating jacket are activated, expelling all water and moisture from the inside, resulting in a completely dry bioreactor. After concluding the process and once the autoclave has cooled to an appropriate temperature, the bioreactor and its components are removed and reassembled, preparing them for the cultivation process.

General recommendations for bioreactor sterilization using an autoclave

- Pre-sterilization cleaning: Before sterilizing, it is essential to disassemble and clean each component of the bioreactor with specific soaps and purified water, including the preparation and the supports used.

- Disassembly of specific components: Following the manufacturer’s recommendations, certain components such as the rotary motor and the condenser should be removed before proceeding with sterilization.

- Exclusive use for reusable bioreactors: Only bioreactors designed for multiple uses should be sterilized in an autoclave. Single-use models are not suitable for sterilization.

- Comprehensive sterilization: Sterilization should cover not only the culture media but also all components of the bioreactor, including filters and valves, to ensure the absence of contaminants. In addition, relevant valves should be opened to allow free circulation of steam over all surfaces of the culture media.

- Selection of the appropriate autoclave: Although pre-vacuum autoclaves are generally preferred for this task, it is important to consider the manufacturer’s indications on the most suitable type of autoclave for each bioreactor.

- Handling of large bioreactors: For bioreactors of considerable size, we recommend the use of integrated cranes, whether fixed or mobile. Consult our range of cranes for bioreactor sterilization in autoclaves and the possibility of adapting our products to your specific sterilization needs.

Considerations for the validation of the sterilization process of bioreactors

- Compatibility and validation: Ensure that the bioreactor is compatible with the media’s formula, the inserted volume and the sterilization temperature and time parameters. Validate each combination empirically and draft the corresponding protocol, using physical and biological indicators at multiple points within the bioreactor to validate the adequacy of your protocol.

- Temperature control: When sterilizing a bioreactor filled with culture media, it is advisable to place a datalogger inside the media to validate the process. This device should record the media’s temperature during the initial validation cycles of the process to ensure that a minimum lethality of F0=20 is achieved, which is a sign of an effective sterilization process in most cases.

- Extension of exposure times: As explained, the sterilization of a bioreactor, whether filled or empty, varies greatly, especially because liquids require a much longer sterilization time. For example, research suggests that subjecting 10 liters of culture media in a 15-liter bioreactor to a temperature of 127°C for 75 minutes might not achieve a lethality of F0=20. In these circumstances, it is advisable to sterilize the culture media and the bioreactor independently.

- Risks of prolonged sterilization: A too-long sterilization period can cause the caramelization of sugars and the accumulation of salt deposits, which deteriorates the quality of the media. It is essential to understand the thermal sensitivity of the media and the impact of the sterilization process on it. In addition to properly adjusting the exposure time in the sterilization phase, it is advised to use an autoclave with fast cooling to minimize the cooling time and thus avoid prolonged exposure of the media to high temperatures during this phase.

- Equipment qualification and maintenance: It is fundamental to perform Installation (IQ), Operation (OQ) and Process (PQ) validations of both the autoclave and the sterilization process to ensure their efficiency and safety. Likewise, it is crucial to comply with the autoclave’s maintenance program to prevent performance issues or downtime.

Compatible bioreactors for sterilization in RAYPA autoclaves

One of the most commonly used types of autoclave for sterilizing bioreactors is the vertical autoclave with pre-vacuum and drying, especially for larger formats. In these, the entry of the bioreactor into the chamber is done from the top, and given the dimensions of some bioreactors that can weigh up to 40kg, it is common to need a crane for handling.

Our autoclaves allow the sterilization of bioreactors from the leading brands on the market. While we have clients working with multiple brands whom we have advised and helped to validate their processes, we always recommend contacting the bioreactor manufacturer to receive technical advice on the bioreactor specifications, how it should be placed in the autoclave, and the temperature and pressure tolerances allowed.

The bioreactor sector is very broad, but if you are looking for a manufacturer, we recommend considering the following leading brands: Sartorius’s Univessel® Glass, Eppendorf’s BioFlo®, INFORS HT’s Labfors 5, IKA’s Habitat, Getinge’s Applikon Bio, Major Science’s Winpact, and Solaris Biotech’s Elara.

Steam sterilization of Getinge’s Applikon Bio Bioreactors using an autoclave

Getinge is a Swedish medical technology company with over a century of experience, specializing in solutions for the healthcare and life sciences sectors, including infection control and intensive care. Among its most notable products are disinfectors, sterilization equipment, surgical tables, ventilators, extracorporeal circulation machines, anesthesia, digital hospital integration solutions and bioreactors.

Getinge’s Applikon Bio bioreactors stand out for their adaptability and efficiency. This glass bioreactor, designed for laboratory-scale cellular and microbial cultures, is compatible with autoclave sterilization, ensuring a sterile environment for safely conducting biotechnological assays. The combination of Getinge’s century-long experience in healthcare and life sciences solutions with the advanced technology equipped in Applikon Bio bioreactors makes them an excellent choice for applications and laboratories of all types.

Do you have a RAYPA autoclave and want to know how to sterilize your Getinge Applikon Bio bioreactor? Contact us and our experts will advise you on the best way to do it. We will be delighted to answer your questions about our equipment and offer our recommendations.

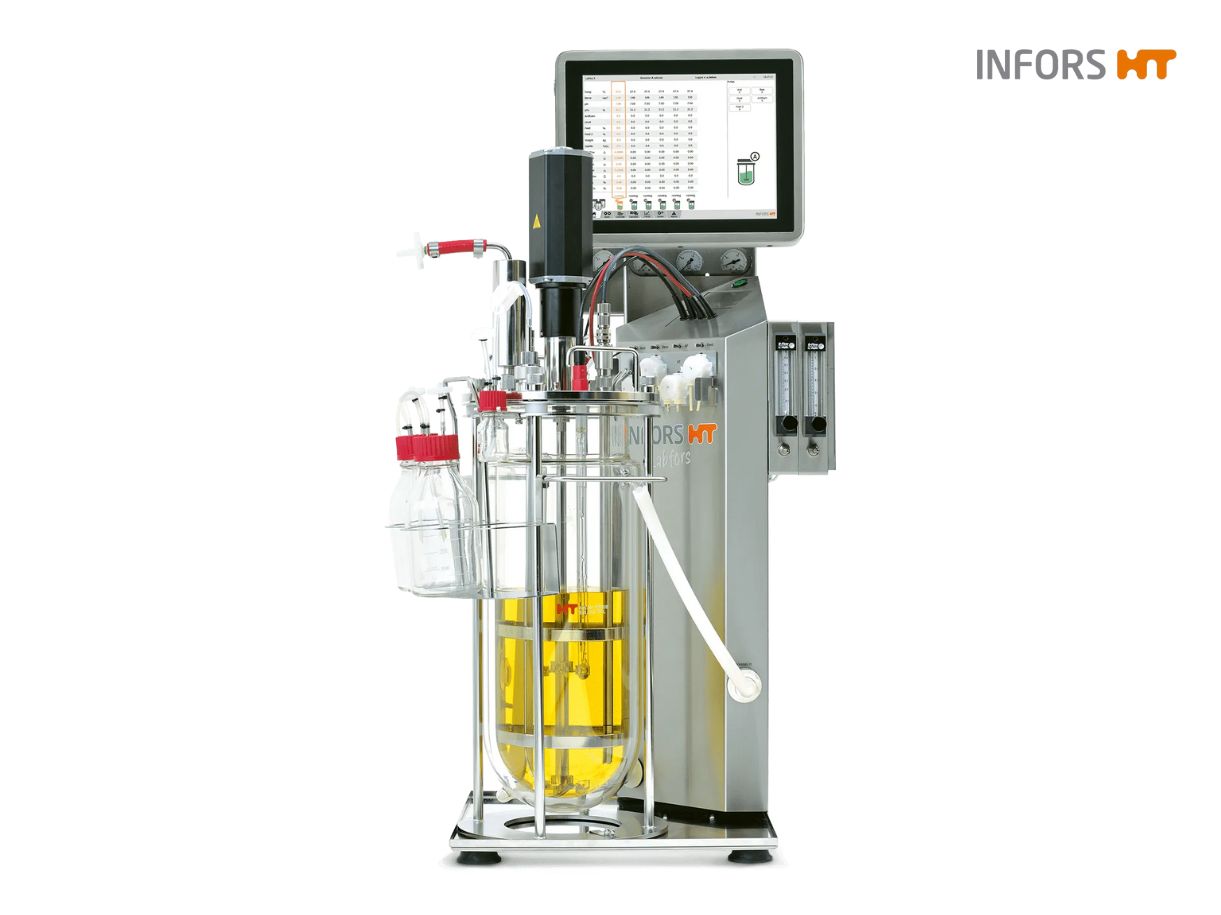

Steam sterilization of Infors HT’s Labfors 5 bioreactors using an autoclave

Infors HT, with over 55 years of history, has established itself as a benchmark in the development and manufacturing of advanced technological solutions for the biotechnology sector. The Swiss company specializes in bioreactors, shaker incubators, and bioprocess control software, significantly contributing to the advancement of research and production in biotechnology, biopharmaceuticals, food technology, cosmetics, agricultural technology, and research institutes globally.

Within the field of bioreactor sterilization, the Labfors 5 from Infors HT stands out as a versatile and effective solution for a wide range of biotechnological applications.

This benchtop bioreactor, designed to adapt to microbial, cellular, enzymatic and phototrophic cultures, is notable for its ability to adjust to different gasification and volume configurations. Moreover, it is designed to be compatible with a wide range of accessories and peripherals to meet the specific needs of each application, making it an ideal tool for researchers and scientists in the field of biotechnology.

Proper sterilization of equipment such as the Labfors using autoclaves is crucial to maintain the integrity and sterility of cultures, thus ensuring the reliability and accuracy of experimental results.

Do you have a RAYPA autoclave and want to know how to sterilize your Infors HT Labfors bioreactor? Contact us and our experts will advise you on the best way to do it. We will be delighted to answer your questions about our equipment and offer our recommendations.

Steam sterilization of Sartorius Bioreactors using autoclaves

Sartorius, with a history spanning over 150 years, has established itself as a benchmark in the life sciences sector, especially in the biopharmaceutical industry. The German company specializes in supporting its clients in the development and production of biotechnological medicines and vaccines, from the initial idea in the laboratory to commercial production. They are undoubtedly one of the foremost experts in this segment and therefore offer a wide range of solutions and products related to this application.

In the context of bioreactor sterilization, the Univessel® Glass, Ambr®, and Biostat® bioreactors from Sartorius represent multipurpose and autoclavable solutions for both research and biotechnological production. They are distinguished by their innovative design, extensive market experience, the wide variety of sizes available, ease of cleaning, and their ability to adapt to various needs within the biotechnological field. The correct use of these bioreactors becomes a fundamental tool for the progress of both the biopharmaceutical industry and scientific research.

Do you have a RAYPA autoclave and want to know how to sterilize your Sartorius Univessel® Glass bioreactor? Contact our experts and they will advise you on the best way to do it. We will be delighted to answer your questions about our equipment and offer our recommendations.

Sterilization of Eppendorf’s BioFlo® bioreactors using autoclaves

Eppendorf is a global leader in the development, manufacturing, and distribution of laboratory equipment and consumables for scientific and clinical research. Founded in 1945 in Hamburg, Germany, Eppendorf offers a wide range of innovative products, such as centrifuges, pipettes, thermal cyclers and incubators, designed to meet the needs of laboratories worldwide.

Among its product portfolio is the BioFlo® bioreactor, designed to meet the research and development needs in biotechnology. These bioreactors are offered with a rounded bottom made of stainless steel for rapid heat transfer, as well as in traditional vessels with a water jacket for smoother temperature control. Each type of vessel is available in four sizes, with multiple agitation options and interchangeable options for top magnetic drive and direct drive.

Sterilizing the BioFlo® bioreactor in an autoclave significantly contributes to ensuring the proper functioning of cultivation processes. This translates into maintaining a sterile and reliable cultivation environment, crucial for ensuring the integrity and viability of cultures.

Do you have a RAYPA autoclave and want to know how to sterilize your Eppendorf BioFlo® bioreactor? Contact us and our experts will advise you on the best way to do it. We will be delighted to answer your questions about our equipment and offer our recommendations.

Sterilization of Solaris Biotech’s IO, JUPITER and ELARA ST bioreactors using autoclaves

Solaris Biotech is an Italian company specialized in bioreactors, fermenters and filtration systems for research and development (R&D) and production purposes. Since its foundation, it has evolved to serve a wide range of sectors, standing out for its commitment to innovation and quality in biotechnology, thus contributing to the advancement of science and productive efficiency.

The bioreactors IO, JUPITER and ELARA ST, developed by Solaris Biotech, are presented as equipment for the field of biotechnology, covering needs in research, process development and small-scale production. These autoclavable devices have been designed to withstand autoclave sterilization processes, which facilitates maintaining the sterile conditions necessary for the performance of cultures.

The autoclavability of these systems is highlighted as a relevant feature to ensure closed aseptic operations, contributing to the integrity and viability of cultures in research and biotechnological applications.

Do you have a RAYPA autoclave and want to know how to sterilize your Solaris Biotech bioreactor? Contact us, and our experts will advise you on the best way to do it. We will be delighted to answer your questions about our equipment and offer our recommendations.

Sterilization of Major Science’s Winpact bioreactors using autoclaves

Major Science is a company specialized in supplying equipment and products for research and biotechnology laboratories. They offer a wide range of solutions that include molecular biology equipment, electrophoresis, DNA/RNA purification, incubation, and shaking, among others. Based in Taiwan and with a global presence, Major Science is committed to providing high-quality products and advanced technology to meet the needs of its customers in the scientific community.

Among their products are the Winpact bioreactors, designed to offer advanced solutions in fermentation and cell culture at an affordable price. These systems are distinguished by their adaptability to various biotechnological applications, allowing precise control of cultivation parameters.

Sterilizing Winpact bioreactors with autoclaves ensures the effective elimination of microbial contamination, securing the integrity and sterility of cultures for research and production processes.

Do you have a RAYPA autoclave and want to know how to sterilize your Winpact bioreactor? Contact us, and our experts will advise you on the best way to do it. We will be delighted to answer your questions about our equipment and offer our recommendations.

Sterilization of Bioreactek™ BIOF bioreactors using autoclaves

Bioreactek™, established in 2010 as part of Labfreez®, is a company specialized in supplying equipment and solutions for bioprocesses and biotechnology. Its main focus is on offering high-quality bioreactors and fermentation systems for research, development, and production applications at an affordable price.

Based in China, the company stands out for its commitment to innovation and quality, providing products that meet the most demanding industry standards. BioReactek also offers consulting services and technical support to ensure the success of its clients in the implementation and operation of their equipment.

Their BIOF series offers a versatile solution for fermentation and cell culture, adapting to the needs of research and development. The BIOF bioreactors, ranging in capacity from 1L to 15L, are designed to be efficiently sterilized in autoclaves, thus ensuring maximum safety and sterility in biotechnological processes.

Do you have a RAYPA autoclave and want to know how to sterilize your Bioreactek™ BIOF bioreactor? Contact us and our experts will advise you on the best way to do it. We will be delighted to answer your questions about our equipment and offer our recommendations.

Why choose our autoclaves for bioreactors?

At RAYPA, we offer a wide variety of autoclaves suitable for the sterilization of bioreactors, with certified quality. Within our range of models, we recommend the top loading autoclaves from the AE-B Series and the TLV-PD Series, belonging to the Classic Line and Top Line ranges, respectively.

Our autoclaves are easy to operate, feature intuitive controls, and possess advanced safety features. Moreover, all of them are available in a vertical standing format, and the larger models have sterilization chambers with large diameter and depth. Below is a summary table of their dimensions.

| Reference | Usable dimensions of the chamber (Ø x H mm) |

|---|---|

| AE-50-B | 300 x 710 |

| AE-75-B | 400 x 600 |

| AE-110-B | 400 x 850 |

| AE-150-B | 500 x 760 |

| TLV-50PD | 400 x 450 |

| TLV-75PD | 400 x 650 |

| TLV-110PD | 500 x 600 |

| TLV-150PD | 500 x 850 |

Their robust construction, outstanding value and straightforward installation make them an exceptional choice for bioreactor sterilization.

In addition to the variety of models, we offer a wide range of accessories available to be equipped, such as bioreactor lifting cranes. These electric cranes can be integrated into the side of the autoclave or be independent and mobile. Both options are equipped with wheels to facilitate the loading and unloading of the bioreactor.

The reliability of sterilization equipment is crucial for both process safety and effectiveness. as well as for upholding production quality in laboratories and workplace settings. That is why all our autoclaves for bioreactor sterilization have been designed and manufactured entirely in our facilities in Barcelona for more than 45 years, a testimony of our commitment to quality and expertise.

This equipment undergoes extensive testing to ensure its quality and to comply with the most stringent regulations and standards, including the European Pressure Equipment Directive (PED). By adopting this approach, we pursue the highest levels of production excellence and ensure the safety of our products.

At RAYPA, we provide comprehensive solutions tailored to meet our customers’ sterilization requirements. With our wide selection of autoclaves and the expert advice of our team, we assist you in finding the equipment that best suits your requirements.

For more detailed and customized guidance on choosing the ideal autoclave, do not hesitate to contact our experts. Working together, we can identify and provide a solution that ensures both efficiency and safety in all your sterilization operations.

Why RAYPA?

GLOBAL REACH

With half a century of experience, we have a lengthy list of satisfied customers around the world. Currently, we export 85% of our annual turnover and have a stable network of distributors in over 100 countries.

EFFICIENT TECHNICAL SERVICE

Our team of highly qualified technicians and engineers is expert in our products. If you experience a technical issue, it will be our priority to rectify it. When you purchase a RAYPA unit, you’re guaranteed top-level support and technical assistance.

EXPERT MANUFACTURER

RAYPA is a global leader in manufacturing laboratory autoclaves. Each of our autoclaves is designed and built entirely at our facilities in Barcelona, ensuring the highest levels of production excellence.

FULL AND CUSTOMIZABLE RANGE

We offer an extensive portfolio of laboratory autoclaves to cover multiple applications and market segments. Discover the combination of autoclave model and accessories that best fits your needs within our 11 series and 35 available models.

INNOVATION AND QUALITY

Our products feature advanced technology, ongoing innovation, superior construction quality, and are designed for a long service life. Our technical and engineering staff works tirelessly every day to optimize our products and exceed our customers’ expectations.

COMPREHENSIVE CONSULTATION

Our team of specialists assesses each project and provides guidance to clients on the option that best suits their requirements. After the sale, we offer training on the use and recommended maintenance of each unit to ensure its optimal operation and extend its lifespan.