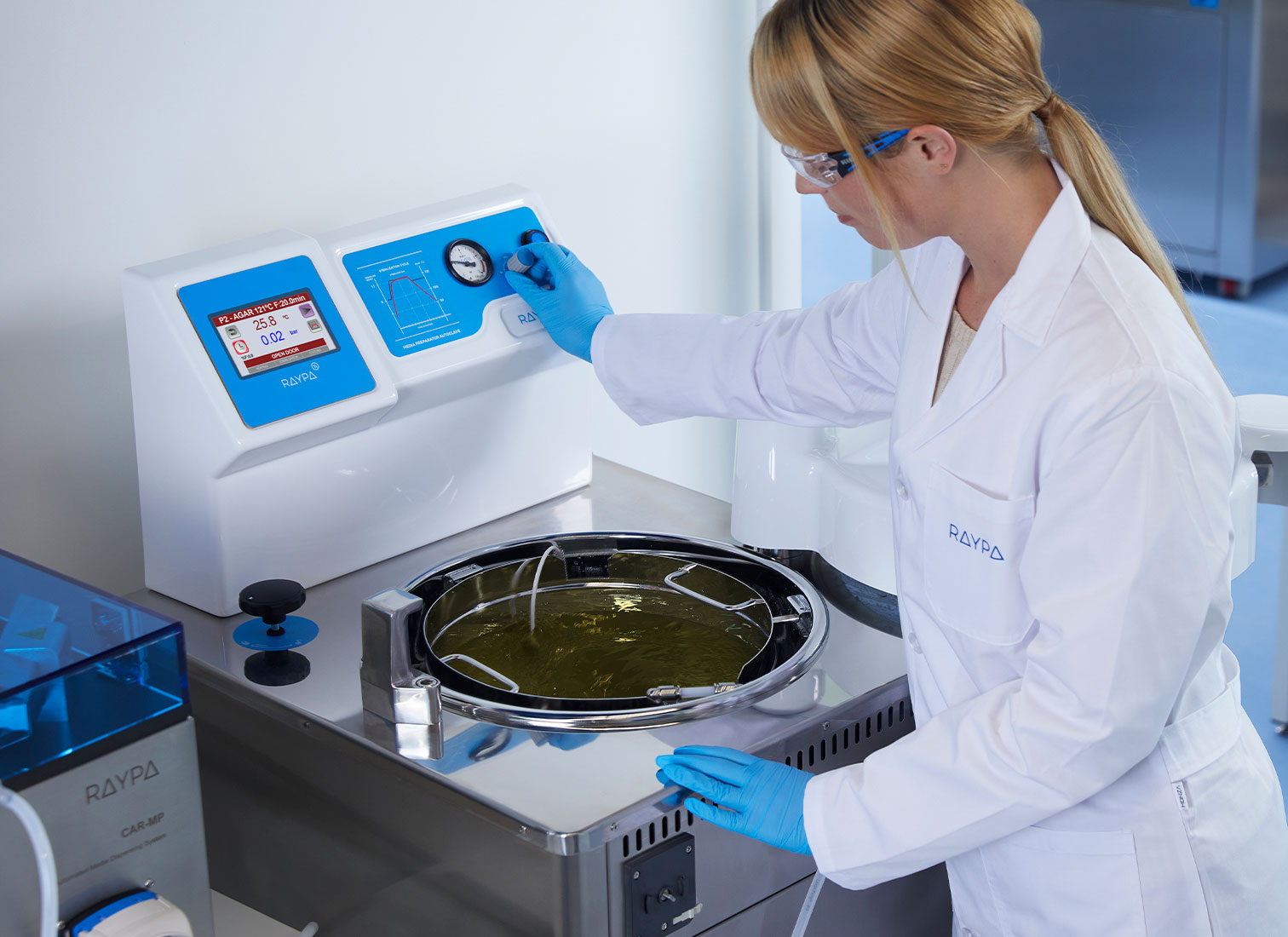

RAYPA media preparators

Our AE-MP and TLV-MP Series media preparators streamline the operative workflow in microbiology and plant tissue culture laboratories. They are designed to reduce the total turnaround time and provide large volumes of sterile culture media thanks to their efficient heating system and fast cooling phase at the end of the sterilization process.

View models

Automatic self-cleaning and disinfection of the dispensing lines

All our models include multiple automatic cleaning processes to save time, minimize the risk of cross-contamination. Thanks to our innovative system of steam injection that internally runs through the dispensing lines, cleaning becomes much simpler and gelation issues of the media are avoided. This system allows for cleaning and disinfecting the dispensing lines before and after each cycle, avoiding the need to clean and autoclave the dispensing lines at each rotation Moreover, during dispensing air pressure can be injected to empty the dispensing lines, allowing for the interruption and resumption of dispensing at another time without problems.

Download brochure

5 processes streamlined in 1 solution

Experience a breakthrough in efficiency with our all-in-one multifunctional device. It merges five key processes: from preparation to dispensing and cleaning. Achieve flawless consistency with fast heating and cooling, meticulous control, and top-tier sterilization offering full traceability. It also provides swift and easy dispensing with an adjustable temperature setting, and concludes with an automatic cleaning of the lines. Streamline your workflow and achieve optimal results with our all-in-one equipment.

Request a quote

FAQS

What is the production capacity of a media preparator?

What are the typical applications of the media preparator?

What options are available for dispensing culture media?

What utilities are required for the installation of a media preparator?

Why RAYPA?

GLOBAL REACH

With half a century of experience, we have a lengthy list of satisfied customers around the world. Currently, we export 85% of our annual turnover and have a stable network of distributors in over 100 countries.

EFFICIENT TECHNICAL SERVICE

Our team of highly qualified technicians and engineers is expert in our products. If you experience a technical issue, it will be our priority to rectify it. When you purchase a RAYPA unit, you’re guaranteed top-level support and technical assistance.

EXPERT MANUFACTURER

RAYPA is a global leader in manufacturing laboratory autoclaves. Each of our autoclaves is designed and built entirely at our facilities in Barcelona, ensuring the highest levels of production excellence.

FULL AND CUSTOMIZABLE RANGE

We offer an extensive portfolio of laboratory autoclaves to cover multiple applications and market segments. Discover the combination of autoclave model and accessories that best fits your needs within our 11 series and 35 available models.

INNOVATION AND QUALITY

Our products feature advanced technology, ongoing innovation, superior construction quality, and are designed for a long service life. Our technical and engineering staff works tirelessly every day to optimize our products and exceed our customers’ expectations.

COMPREHENSIVE CONSULTATION

Our team of specialists assesses each project and provides guidance to clients on the option that best suits their requirements. After the sale, we offer training on the use and recommended maintenance of each unit to ensure its optimal operation and extend its lifespan.